If planning to upgrade or replace your nameplate from the stable, the variety of materials available, including stainless steel and aluminum, may be daunting. While both stainless steel and aluminum are used most often for nameplates, brass is a favorite choice. Brass, being its good appearance and infinite practical advantages, turns out to be the ideal material for stable nameplates. The synergy of beauty and utility value makes brass the optimum choice for this use.

1. What Is a Brass Name Plate?

Brass name plate is a durable identification or name plate made of copper–zinc alloy known as brass. Brass name plates are employed to display names, serial numbers, company logos, product information, or commemorative messages. Brass is a valuable metal that combines the golden appearance with mechanical strength and resistance to corrosion. Therefore, it is one of the most sought-after material for utilitarian as well as decorative name plates.

Structurally, a brass name plate is typically a flat brass sheet engraved, etched, or printed with desired text or images. Depending on the intended use, the surface may be polished to mirror finish, brushed to satin finish, or lacquered or clear enamelled for oxidation protection. Mounting holes, adhesive tapes, or threaded inserts can be added to the plate to enable direct mounting on walls, doors, machines, or show racks.

Also, it is color stable and dimensionally correct even in exterior or industrial usage, and thus well-suited to long-term signage, equipment identification, and memorial plaques.

Finally, brass name plate is more than a tag of information; it’s a marriage of engineering utility and aesthetics. Used in architectural signage, corporate identification, or historic signage, brass plates convey a level of heritage, professionalism, and weight that few materials can match.

2. Overview of Name Plate Materials and Selection Principles

Choosing the appropriate material is one of the critical processes in manufacturing a high-quality name plate. The selection impacts not just how the plate appears but also how durable it will be, how resistant it is to corrosion, and how much money it will take to produce. Different materials possess their strengths and best applications, thus knowing the difference enables the optimum outcome for any project.

Some of the popular materials for the manufacture of name plates include brass, stainless steel, aluminum, plastic, and composite materials.

Brass offers a classic golden appearance and a commanding sense of elegance. It is a combination of hardness with decent weight and exceptional corrosion resistance, making it suitable for ornamental and professional purposes.

Stainless steel is very resistant and resilient to water, heat, and chemicals. It is ideal for machinery used in industry, marine environments, and external signage exposed to severe weather conditions.

Aluminum is lightweight and inexpensive. It is easy to machine and anodize, and this allows it to be possible for multiple color finishes, and therefore it is very common in mass production or light use.

Plastic materials such as acrylic or PVC are color- and shape-adaptable and often will be interior signs or short-term identification.

Composite plates wed multiple layers, often a metal surface over plastic core, offering a balance between cost and longevity.

When materials are judged based on how they perform, a number of factors are considered.

- Among all the materials on durability, stainless steel and brass are the most resilient, being able to stand physical touch and resisting exposure. Aluminum is relatively durable, while plastic scratches and deforms easily.

- In terms of resisting corrosion, stainless steel stands out, followed by brass. Aluminum resists rust but oxidizes in extreme durations, and plastic degrades or warps when exposed to UV light.

- As for expense, plastic and aluminum are the most affordable and brass and stainless steel are slightly expensive due to their material and finishing requirements.

- For machinability, brass and aluminum are easiest to cut, engrave, or polish but stainless steel requires more advanced equipment. Plastic is easiest to mold but lacks the upscale feel of metal.

- When it comes to appearance, brass stands out with its golden warm color, stainless steel with its shiny silver look, and aluminum with a matte clean finish. Plastic and composites can reproduce any of these but usually not with the same texture or weight.

| Material | Durability | Corrosion Resistance | Cost Level | Machinability | Appearance Characteristics | Typical Applications |

| Brass | High | High | Medium to High | Easy to moderate | Warm golden tone, elegant and classic | Decorative plaques, name plates, awards, signage |

| Stainless Steel | Very High | Excellent | High | Difficult | Modern silver tone, industrial style | Outdoor signs, industrial labels, marine use |

| Aluminum | Medium | Moderate | Low to Medium | Very easy | Matte metallic look, lightweight | Office plates, product labels, bulk production |

| Plastic (Acrylic, PVC) | Low to Medium | Moderate | Low | Very easy | Colorful, lightweight, versatile | Indoor signs, temporary displays |

| Composite Materials | Medium to High | Good | Medium | Easy | Metal-like surface with lightweight core | Cost-effective durable signage |

There are several situations where brass must be the best choice. It is most suitable for decorative signs, memorial plates, door plates, awards, and historical signs where performance in terms of visibility and durability is most important. Brass is also suitable in more premium commercial settings such as hotels, offices, and department stores where it adds to the brand image with the perception of luxury. Further, for indoor applications where there may be moisture or less outdoor exposure, brass does not suffer from loss of luster due to degradation.

Short and sweet, selection of name plate materials needs to strike a balance between look, durability, and cost. Brass offers the ideal balance of looks and strength, and hence is one of the best options if both look and long-term value are involved.

3. Why is brass the perfect material for permanent name plates?

Brass nameplates are renowned for their higher strength and endurance. Brass is the only material that possesses the unique feature of standing the test of time without weakening its structural integrity and visual appeal, even in extreme conditions. Tough enough to survive different types of weather, indoor and outdoor, brass nameplates become a valuable choice for organizations and businesses seeking permanent signage products.

1) Superior Durability

Brass is a zinc and copper alloy that has been found to be hard and highly durable. That natural resistance, then, is such that the brass name plates can stand water exposure, sunshine, heat, and cold as well. With the composition of brass, the name plates are suitable for placement in factories, offices, and open spaces since they yield clarity and resistance for a very long time without frequent replacement.

2) Durability in Harsh Conditions

Brass, copper-zinc alloy that is strong and hard-wearing, is greatly cherished for its hardness and durability. Such natural toughness renders brass nameplates immune to exposure to water, sun, heat, and cold without suffering any compromise in integrity.

Being made of brass, these nameplates are best suited for industrial settings, commercial buildings, and outdoor spaces, as they remain clean and intact for a very long time, and hence become a long-lasting and uniform choice.

3) Aesthetic Appeal and Versatility

The agelessness of brass nameplates lies in their longevity and stunning appearance. Adopting either old-world or modern design themes, brass can easily complement both themes with its warm tone and reflective finish. Its longevity allows it to glow on classic settings as well as modern interior designs, providing the overall aesthetic value of any place.

4) Timeless Elegance

Brass exudes refined elegance outside of trend cycles, so it is one that can be harmonized with any style trend. Its reddish orange to orange color adds a warm and energetic ambiance to any room.

No matter where installed to wrap around walls, doors, cups, or keychains for branding, wayfinding, or identification purposes, brass creates sophistication and personality that engages observers.

5) Design Flexibility

The strongest advantage of nameplates is that they allow creative freedom for persons who seek out brass nameplates. These nameplates are their own canvas in which personalized logo and typography may be featured, reflecting the business brand and marketing message to consumers.

With engravings like engraving, etching, and embossing, every nameplate becomes custom-made to be different with a special, unique aspect placed on each individual one.

6) Corrosion and Weathering Resistance

The better corrosion resistance and superior weather of brass nameplates gives them an added advantage to endure outdoor conditions where degradation is sure to occur. Unlike steel or aluminum, that rusts or corrodes on exposure to humid or wet situations, brass nameplates are always durable and legible.

It ensures the high quality and proper functioning of the nameplates within and outside as well.

7) Corrosion Resistance

Corrosion resistance of brass is because brass has a unique composition. Brass, when it is exposed to oxygen or water, develops an oxide layer over it that acts as a protective coating to prevent corrosion of the metal. The protective coating is so efficient that it prevents any subsequent oxidation or corrosion and makes brass nameplates rust- and tarnish-resistant even if left outdoors in rain, snow, or humidity.

8) Weathering Resistance

Brass nameplates are highly weather-resistant and can withstand sun, UV, and temperature fluctuation. They are not like plastic or acrylic ones that become distorted and degrade over time and become illegible. Brass nameplates are readable and look good as they are heat- and humidity-resistant.

This resilience renders brass nameplates extremely well-suited to weathering, as in applications like building signage and outdoor plaques, where they can endure a great number of types of weather and hold together.

9) Customization Options and Personalization

Brass nameplates are offered in several customization options depending on personal need and preference. Engraving and etching, as well as color filling, are available design techniques. These design techniques allow for logos, text, and graphics use, allowing the nameplate to express the individual identity of the entity it carries.

This level of tailoring ensures that all nameplates are crafted to particularly meet specific requirements and embody the essence of the organization it represents.

10) Versatile Design Possibilities

The designs are endless with brass nameplates. Engraving techniques are commonly applied to create patterns, company identification with names and logos, or simply text in a unique style. Etching allows detailed and fine lines and artistic designs to be created.

Besides, color filling can also be employed to create highlights on specified areas over the brass surface, inducing depth and visual appeal to the whole design.

11) Personalized Branding

For those businesses seeking to improve their brand reputation through personalization by means of branding, brass nameplates are a great choice. With logos of businesses, slogans, and mission statements inscribed on the nameplates, businesses can assert their identity and values publicly to the general audience and visitors alike.

Such attention does not simply demonstrate professionalism but also makes the brand image stronger, leaving a lasting impact on anyone it meets.

12) Tailored Solutions for Specific Needs

From door plaques for the office to nameplates and commemorative plates, brass nameplates can be crafted specifically to meet specific requirements. Brass nameplates can be manufactured to a standard size and shape by companies or custom-created to the company’s specifications.

A level of such customization implies that each nameplate serves its purpose as well as contributes to the aesthetic of the space it occupies.

4. Brass Name Plate Design and Production Essentials

Design takes precedence to create an aesthetically appealing and functional name plate. An effective brass name plate applies the correct proportion, lettering style, engraving method, and surface finish to convey brief information and lasting beauty. The following are the top considerations to create professional outcomes.

1. Size and Shape Selection

The size and shape of the brass name plate must be suitable for its use and mount location. For office doorplates or business signs, a rectangle or oval with related dimensions looks nice and professional. Circular or custom plates are also often used for decorative or artistic functions. The size must be large enough for all the text and graphics and remain legible from the intended viewing distance. If unsure, slightly larger sizes are preferable for good legibility and visual equilibrium.

2. Text, Font, and Layout Recommendations

Text clarity is necessary. Use fonts that remain legible when engraved or engraved on metal. Employ fonts that are legible even when they are engraved or etched in metal. Helvetica or Arial sans-serif fonts provide a minimalist and clean appearance, while serif fonts Times New Roman or Garamond provide a sophisticated and traditional look. Employ line and character spacing generous enough so as not to clutter them.

3. Logo, Pattern, and Texture Considerations

When combining patterns or logos, vector graphics need to be provided in order that laser cutting or engraving are accurate. Detailed areas are minimized because thin lines cannot be accurately replicated in metal. Brushed and sandblasted textured backgrounds enhance contrast and legibility. Pairing a reflective logo with a two-dimensional background typically results in good visual hierarchy.

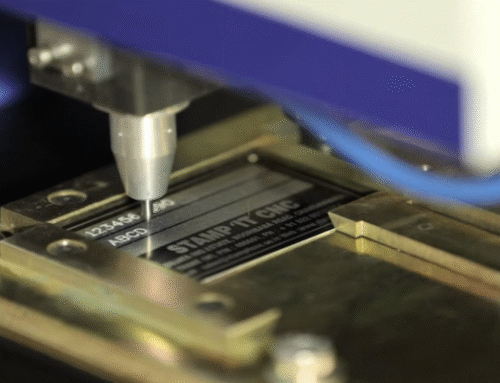

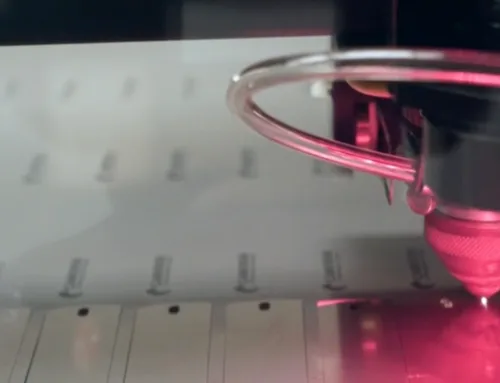

4. Engraving, Etching, Laser, and CNC Techniques

Different production methods create different effects. Traditional engraving removes the design straight out of the brass surface, which creates a clean and classic look. Chemical etching chemically dissolves the material by using chemicals or another material to create depressed areas, ideal for small detail and high quantities. Laser marking has fine resolution and can quickly duplicate detailed graphics without touching them. CNC machining creates deep and three-dimensional effects that are ideal for high-end or heavy plates. Choice of method is dependent upon desired depth, texture, and cost.

5. Coloring and Fill Methods

After engraving or etching, colour can be added to increase beauty and contrast. Enamel, paint, or resin are common fill materials. Black, dark green, or navy blue are dramatic colour contrasts with brass, but clear lacquers can permit the underlying golden colour to show. Proper curing and sealing of the colors make them look rich and prevent peeling or fading.

6. Mounting and Installation Options

There are several mounting options depending on the area where the plate will be mounted. Screw mounting provides permanent and secure fixing on doors and walls. Adhesive backing provides clean and simple installation on smooth indoor surfaces. Bolts and studs are perfect for outdoor or heavy plates with concealed fixtures behind the surface. Welding or soldering is suitable for industrial application when ultimate strength is required. Temporary exhibits or ornamental plaques may use hanging systems or hooks. Always ensure that the mounting system is suitable for the plate’s weight and the material to which it will be fixed.

7. Structure and Thickness Recommendations

The thickness of a brass name plate affects not just its appearance but also its structural strength. Plates with a thickness of 1 to 2 millimeters are suitable for general applications, while outdoor or large-format signs may require 3 to 5 millimeters for rigidity. Thicker plates will be more resistant to bending and increase the perception of quality but also add weight and cost. Edges can be beveled, rounded, or flat as per finish required. A small structural margin should always be reserved to withstand deformation when engraving or mounting.

5. Diverse applications of brass name plates

Brass name plates are among the most versatile identification and decorative pieces used across different industries. Their capacity to combine durability, aesthetics, and professional tone makes them suitable for both utility identification and brand statement. Below are the most common fields where brass name plates are heavily used.

1. Architectural and Residential Signage

In architectural design, brass name plates are employed across the board for door numbers, building directories, mailboxes, and address plaques. Their gold glow adds warmth and sophistication to any entrance or lobby. Over time, the natural patina that occurs on brass adds an antique loveliness, which makes it a popular choice for heritage buildings, luxury apartments, and residences.

2. Corporate and Office Branding

Brass name plates are utilized by many companies for door signage, reception logos, and building directories to convey professionalism and stability. The material’s refined tone suits modern interiors, and engraved logos and polished finishes add to brand visibility. Custom shapes and finishes, such as brushed or mirror polish, allow the design to be tailored to corporate looks.

3. Industrial and Equipment Labeling

Aside from ornamentation, brass is also valued for its technical reliability. Brass plates are often used in workshops, factories, and laboratories as machine labels, serial number plates, and warning notices. The material withstands heat, vibration, and chemical exposure more effectively than most plastics, ensuring that information remains legible after decades of service.

4. Memorials and Commemorative Plaques

Brass is traditionally associated with respect and remembrance. It is routinely used for memorial plates, dedication plaques, trophies, and awards. The golden color reminds one of remembrance and dignity, and engraved or etched lettering ensures that the names and dates are readable for generations to come. The plates are generally mounted in universities, parks, museums, and public buildings.

5. Retail, Hospitality, and Luxury Spaces

At restaurants, boutiques, and hotels, brass name plates help achieve a luxury customer experience. They are widely used for numbering rooms, name plates at counters, product labels, and menu boards. The metallic sheen of the material goes well with high-end interiors, and it gives the impression of elegance and dependability.

6. Cultural, Artistic, and Decorative Uses

Brass plates are also used in art exhibitions, furniture construction, and custom crafts. Artists and designers choose brass because of its versatility and warm color, which goes well with wood, glass, or leather. Brass conveys quality and authenticity, whether for gallery identification tags or signature plates on artwork or instruments.

7. Outdoor and Public Applications

Properly surface-coated, brass weathers well outdoors. It is frequently used for direction signs, monument lettering, and municipal notice boards. For these uses, the plate must resist weathering while staying legible and visually balanced. A protective coating or lacquer clear maintains the luster in spite of sun and rain.

In summary, the diverse applications of brass name plates show how a single material can meet both functional and decorative needs. Whether as a durable machine tag or sophisticated ornament, brass always brings strength, precision, and timeless beauty along with it.

6. Brass Name Plate Cost Estimation and Budget Guide

Being aware of the cost structure of brass name plates allows designers and buyers to plan ahead. The price varies according to material thickness, surface treatment, engraving process, and the number produced. By considering the above elements in advance, one can provide the desired quality and aesthetics within a reasonable budget.

1) Price Range by Size and Process

The cost of a brass name plate depends on several key parameters: the size and thickness of the brass plate, the complexity of the design, and the production process. The following table provides a rough guide for small to medium orders.

| Specification | Typical Thickness | Processing Method | Common Finish | Estimated Price Range (USD per piece) | Suitable Application |

| Small plate (50 × 100 mm) | 1–2 mm | Laser engraving | Brushed or polished | 3 – 8 | Personal name tags, small indoor labels |

| Medium plate (100 × 200 mm) | 2–3 mm | Chemical etching + paint filling | Polished or lacquered | 8 – 18 | Door signs, office plaques |

| Large plate (150 × 300 mm or above) | 3–5 mm | CNC engraving or deep etching | Polished, antique, or mirror finish | 20 – 40 | Building directories, commemorative plaques |

| Customized shapes or embossed designs | 2–5 mm | CNC + color filling | Polished or antique | 25 – 60 | Decorative branding, luxury signage |

| Bulk order (over 500 pcs) | varies | Laser or etching | Brushed or matte | 2 – 5 | Industrial or equipment labeling |

These prices are approximate and may vary depending on brass grade, finishing type, and local labor rate. Additional features such as protective coating, adhesive backing, or mounting hardware can also affect the final cost.

2) Cost Control Strategies

Some ways to optimize cost without compromising the quality of the final product are given below:.

- Maximize simplicity of design. Avoid using very complex graphics or extremely deep engravings if the same legibility can be achieved with shallower or simpler cuts. Simple designs reduce engraving time and conserve material.

- Vary thickness according to application. For indoor use or lightweight signage, a 1.5–2 mm plate will generally suffice. Only outdoor or structural applications require thicker plates.

- Benefit from batch production. Buying in larger quantities significantly reduces the unit price, as setup and tooling costs are divided among more products.

- Standardize sizes. Using standard plate sizes or template shapes minimizes cutting and setup time.

- Choose practical finishes. Brushed or matte finishes are cost-effective with a professional appearance, rather than mirror or antique finishes requiring extra polishing and coating work.

Through the use of these techniques, a balance can be achieved between visual quality and manufacturing efficiency.

3) Alternative Options for Limited Budgets

Where the budget is low but the look of brass is still justified, there are several alternative solutions that can be used.

- Plates of anodized aluminum provide the appearance of metal such as brass at a lower cost. They are lighter, resistant to corrosion, and can be printed or laser-marked in a range of colors.

- Brass-plated composite plates use a thin coating of brass on a plastic or aluminum base, offering the same gold appearance at reduced material cost.

- Metallic-coated plastic plates mimic the sheen of brass for indoor short-term display, making them suitable for events or temporary signages.

- Hybrid constructions with brass for the text area or logo and aluminum for the base plate can also reduce the overall cost while preserving the high-end look.

These choices allow the aesthetics of branding and design consistency to be maintained within budget.

In conclusion, effective cost planning for brass name plates is about understanding how material thickness, process, and quantity interact. With smart design choices and sufficient communication with suppliers, quality name plates with the intended aesthetic and financial outcomes are possible.

7. Brass Name Plate FAQs

1. Can brass name plates be used outdoors?

Yes. Brass name plates can be used outdoors when they are sealed with a protective lacquer or clear coat. The coating prevents oxidation and tarnishing from exposure to air and water. When used in coastal or high-humidity areas, regular cleaning and re-coating every few years will maintain the shine and color.

2. Will the brass surface change color over time?

Brass will naturally develop a thin oxide layer known as patina. This gives the metal a warmer, older color that is attractive to many users. To keep the bright gold look, a clear protective coating may be added or the surface may be polished periodically with a soft cloth and non-abrasive cleanser.

3. What is the standard thickness for brass name plates?

Standard thicknesses range from 1 to 3 millimeters for general applications. Thinner material of around 1.5 millimeters may be utilized for wall-mounted or indoor signage, and thicker material of 3 to 5 millimeters must be utilized for outdoor mounting or large-format designs that need more stiffness.

4. How are brass name plates typically installed?

They may be screw-mounted, adhesive-backed, bolted, or installed via hanging systems. Double-sided industrial adhesive is suitable for mounting on smooth indoor surfaces. For heavier plates or outdoor use, screws and bolts offer greater stability. The mounting surface should always be cleaned and leveled prior to mounting.

5. Can the design include logos, images, or custom shapes?

Yes. Through advanced production techniques such as laser engraving and CNC machining, custom designs with high precision are achievable. Company logos, QR codes, serial numbers, or decoration can be added. We accept vector files in formats such as AI, EPS, or PDF to achieve crisp engraving results.

6. How long does production usually take?

Production time varies by design complexity and order size. Simple engraved plates can be completed in 5 to 7 working days, but larger or irregularly shaped plates may require 10 to 15 days including finishing and coating. Bulk orders can take additional time for setting up and packaging.

7. How to clean and maintain a brass name plate?

Clean the plate regularly with a soft cloth and mild soap solution. Avoid abrasive materials that could scratch the surface. For polished brass, use a specialized brass cleaner to remove oxidation and restore shine. Applying a thin layer of protective wax can also reduce future tarnishing.

8. Is there a minimum order quantity (MOQ)?

Most suppliers are able to offer flexible quantities based on the manufacturing process. For engraved or CNC-machined brass plates, MOQ is generally 10 to 50 units. Nevertheless, sample orders or prototypes can commonly be produced for design approval prior to volume manufacturing.

9. Can I request a sample before confirming the full order?

Yes. Sample production is offered by most suppliers for material and finish confirmation. There is sometimes a small sample fee that will normally be deducted from the bulk order quantity. Samples ensure that size, color, engraving depth, and finish are correct before production is started.

10. What should be provided when placing an order?

Purchasers must prepare design files (preferably in vector format), confirm dimensions, specify surface finish and mounting technique, and provide quantity requirements. Clear communication here prevents errors and enables faster production turnaround.

8. Conclusion

Briefly, brass nameplates offer a plethora of benefits that make them the top choice of business people all over the world. Durability, strength, reliability, and weather and corrosion resistance make them stand way ahead as a superior signage product. Personalization adds a personal touch to each nameplate, making it suitable for the company’s image and personal style.

As a symbol of high quality and durability that contributes to the prestige and professionalism of an institution, brass nameplates remain the preferred choice for the majority of institutions. They find application in staff identification or commemorative plaques and provide elegance and class that leaves a lasting impression on visitors and clients.

Brass nameplates are not only durable signs but also emblems of excellence, professionalism, and dependability. In business, brass nameplates establish a good brand reputation that is wide and long-term, projecting attention to excellence and timelessness.

Leave A Comment