Epoxy dome stickers have emerged as a mind-of-the-moment choice for giving a touch of personalization and ruggedness to products. They are constructed from a combination of resin and hardener, which sets to create a hard and reflective surface that will never be removed. Join us on the quest to learn about the world of epoxy dome stickers and discover everything about what they are capable of doing in terms of quirky features, benefits, and uses for various applications.

1. What are epoxy dome stickers?

Epoxy dome stickers are small adhesive stickers created by encapsulating an inked image beneath a clear layer of epoxy resin. The resin becomes glossy and glass-smooth upon hardening, creating a three-dimensional appearance that expands colors. Aside from appearances, the coating is better for scratch protection, UV protection, and water protection, ensuring the printed image stays vividly and strongly longer.

2. Highlight features of epoxy dome stickers

Epoxy stickers boast a range of impressive traits that set them apart from the pack in the world of custom stickers. From their fascinating 3D look to their resilience and visual flexibility, these stickers have a wealth of advantages.Let’s highlight some key features:

1) 3D Visual Appeal

Epoxy dome stickers have a domed three-dimensional appearance that sets them apart from most flat stickers. This style gives a shiny, high-end finish to any craft without the use of costly materials and equipment.

2) Durable

Epoxy dome stickers possess a thick, transparent resin that is extremely water-resistant, scratch-resistant, and sunlight-resistant. Its thick design ensures that they will last longer and will be able to maintain their vibrant colors and will not wear off or get weakened with time.

3) Decorative

Crafters and DIY enthusiasts adore these domed stickers for their power to provide a decorative finish to so many products. From scrapbook pages and cards to journals, phone cases, laptops, and many others, these stickers provide a creative touch that makes the appearance of your projects go from run-of-the-mill to fantastic.

4) Cost-effective

They offer a stylish, high-quality look with the inclusion of them into a project without breaking the bank in equipment or material expense. And they are also an inexpensive option for other forms of decoration or specialty printing.

5) Easy to Apply

Find the secret to achieving a professional, high-end appearance for your projects without breaking the bank with these budget-friendly epoxy dome stickers. No more need for costly equipment or materials since these stickers offer a cheap alternative that beats other custom printing and decoration methods.

6) Customizable

Let your imagination take flight with epoxy dome stickers in an unlimited set of shapes and sizes, with the ability for unlimited customization. From personalized designs, logos, or words, these stickers are perfectly suited for an unlimited range of applications, so well-suited to branding and marketing campaigns.

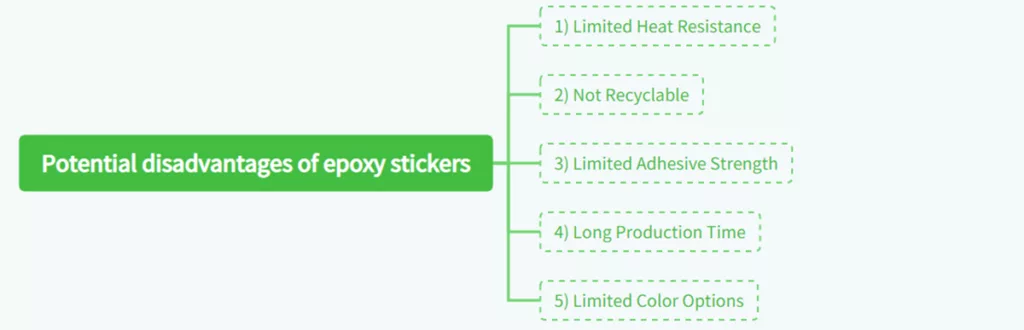

3. Potential drawbacks of epoxy stickers

Although epoxy dome stickers are beneficial in several senses, an understanding of their potential weaknesses beforehand will be helpful in determining whether they would be suitable for your requirement or not. An understanding of their advantages and disadvantages will help you make a judicious decision regarding the usage or non-usage of these stickers.

1) Limited Heat Resistance

Epoxy dome stickers can be deformed or damaged by excessive heat. This makes them not ideal for applications where heat exposure is common, like on kitchen tools or car components.

2) Not Recyclable

Epoxy dome stickers are not recyclable because they contain the adhesive and resin which they utilize to make them. They can be harmful to the environment as well as generate waste.

3) Limited Adhesive Strength

Even though epoxy dome stickers have a self-adhesive backing, their adhesive is not very strong to stick to certain surfaces, including porous and uneven materials, without adding other adhesives.

4) Long Production Time

Epoxy dome stickers and decals are done a lot of effort since it is a multi-process task that involves printing, cutting, and coating the epoxy resin. It might not be an ideal process in project timing or even when one needs to do something urgently.

5) Limited Color Options

Epoxy dome stickers can be of fewer colours compared to normal forms of printing because the epoxy resin can slightly colour the colours or restrict colour choice when printed.

It is worth considering the drawback of epoxy dome stickers in relation to the benefits when you are deciding how you want to label or ornament your project. Understanding the drawback will enable you to make an educated decision that will be most suited to you and your application.

4. What are 3D epoxy dome stickers used for?

Epoxy dome stickers are not just cosmetic products. They are combinations of beauty, durability, and functionality, applicable to multiple industries. Their reflective three-dimensional appearance, touch-sensory smoothness, and scratch- or fade-proof nature make them capable of making products both beautiful and authentic. The following are the main application areas where epoxy dome stickers offer functional and aesthetic value.

1. Branding and Product Identity

Epoxy dome stickers are ubiquitous as trademark symbols or logos on products, packages, and devices. The clear epoxy laminate protects colors and detail and provides a shiny and businesslike appearance that commands customers’ attention.

Electronics, home appliances, home furnishings, and sporting goods often sport domed emblazonings of company names or certification logos. Small firms and startups can afford epoxy stickers as a cheap means of attaining upscale appearances without costly metal or engravable badges. The three-dimensional surface also offers an upscale touch-and-feel that supports brand imagery and credibility.

2. Decorative Enhancement and Visual Appeal

The elegance of epoxy dome stickers is the ability to produce dazzling graphics into unique design elements. Their shiny face reflects light at different angles, creating brilliance and depth that plain labels cannot offer.

They are used extensively inside vehicles, house appliances, and home electronics to reinforce control buttons, logos, or tactile surfaces. On the manufacturing and design side, epoxy stickers are desirable seals on customized items such as notebooks, key chains, or product packages.

3. Product Identification and Information Labeling

Besides aesthetics, epoxy dome stickers play a critical role in product identification. They can be printed with serial numbers, model numbers, or product information under the transparent resin coating and are scratch- and water-resistant.

Manufacturers apply such labels on equipment panels, machines, and consumer electronic devices where legibility and wear resistance are crucial. The transparent epoxy coating not only guards against printed information but also enhances readability in varying lighting. Domed labels hence offer a handy solution in the cleanroom environment where abrasion or heavy cleaning would ruin standard printed labels.

4. Security and Anti-Counterfeiting Applications

In situations where authenticity is crucial within an industry—such as electronics, automotive parts, and medical equipment—epoxy dome labels are coupled with security features to deter counterfeiting.

The process of production allows for special customization like microtext, holographic images, and serialized identifiers that are encoded beneath the epoxy layer. The above features make copying quite difficult through traditional printing or copying techniques.

Further protection can also be achieved using tamper-evident adhesives. These stickers, when removed, leave evidence or patterns showing evidence of unauthorized access or substitution. Along with electronic verification processes such as QR codes or serial number lists, epoxy stickers can be both physical and electronic verification solutions, enabling brands to maintain customer trust and compliance.

5. Promotional and Gift Applications

Epoxy dome stickers are also used in campaigns and gifts due to their vibrant color and cost. They are placed on keychains, mementos, bottle caps, stationery, and event favors to hold business logos or theme prints. Their shiny dome finish adds promotional products with a premium, sophisticated glaze that makes recipients hold on and reuse them, leaving them in sight for longer periods.

As a touch-and-hold, long-lasting impression of a company for corporate functions or product launches, personalized epoxy decals and badges are the best option. Epoxy dome stickers combine form and function in numerous applications across different industries. Whether for branding, decoration, identification, security, or promotion, they provide a resilient and attractive labeling solution. Their transparent three-dimensional look, pliability, and protective layer make them the best choice for businesses that need beauty and functionality combined in presenting products and communicating brand.

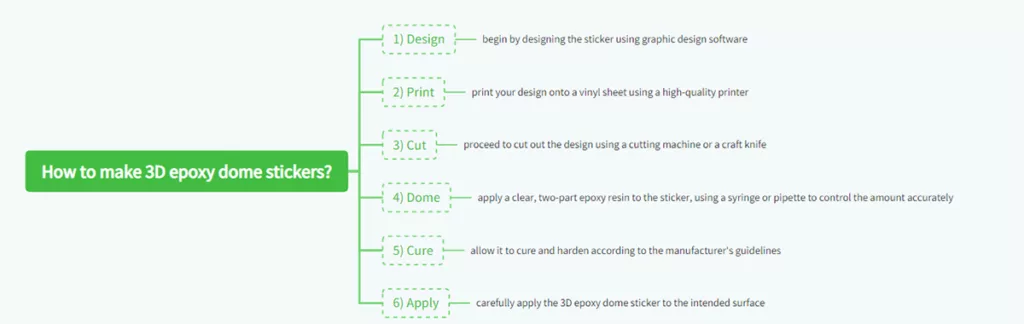

5. How to prepare 3D epoxy dome stickers?

Preparing 3D epoxy dome stickers is a simple yet creative process through which you are able to individualize stickers as per your need. Let’s discuss the procedure of preparing your own 3D epoxy dome stickers step by step in detail.

1) Design

To begin your preparation of your 3D epoxy dome stickers, start off by developing the design of the stickers on graphic designing software. The design used should be one that is compatible with the 3D appearance as well as other factors such as size, shape, color, and accurate details in order to eventually come up with a desired end product.

2) Print

Finally, print your design onto a vinyl sheet with a quality printer. Waterproof and fade-proof ink must be utilized to maintain durability and longevity in your 3D epoxy dome stickers.

3) Cut

Once the design has been printed onto the vinyl sheet, cut out the design with a cutting machine or craft knife. Be precise to get the right shape and size for your 3D epoxy dome sticker.

4) Dome

Second, use a transparent, two-part epoxy resin and apply to the sticker using a syringe or pipette in measured amounts. Apply evenly to prevent air bubbles.

5) Cure

Allow the epoxy resin to harden and cure according to the instructions provided by the manufacturer. Curing will take hours or days depending on the type of resin used.

Carefully peel off the backing strip once applied. Cut off any excess resin along the edges with scissors or a craft knife to achieve a shiny and clean finish.

6) Apply

To complete the process, set the 3D epoxy dome sticker carefully onto the surface of preference, having made sure it is smooth and clean of any dust or dirt.

3D epoxy dome stickers are constructed using high-technology equipment and materials but also prove to be an easy, rewarding, do-it-yourself project for enthusiasts and crafty individuals. Ensure that you only remember safety considerations by doing the same in a well-ventilated area and while handling epoxy resin, gloves on. Following safety precautions, you will be able to design your stickers in an easy and trouble-free way.

6. How to Choose Epoxy Dome Stickers?

The application of an epoxy dome sticker depends heavily on stress resistance in the environment. Hot environments, like machinery or weather exposure, may lead to yellowing or softening of standard epoxy resin. Under such conditions, use stickers made with UV-stabilized or heat-resistant epoxy to maintain strength and clarity.

1. Environmental Analysis (Temperature, Humidity, Chemical Exposure, UV Light, and Mechanical Impact)

Humidity can influence the adhesive layer, especially on metal or coated substrate. Moisture-resistant adhesives will keep the peeling and bubbling at bay. In chemical exposures like in the laboratory, car components, or industrial equipment, stickers must be alcohol-, cleaner solution-, and oil-resistant so that they do not deteriorate the resin or dissolve the ink underneath.

Ultraviolet light is an important aspect of outdoor use. Yellowing or degradation due to UV exposure over a very long period of time is a factor. Adding UV inhibitors to the epoxy or a clear protective topcoat will significantly enhance lifespan.

For equipment or products that will be subjected to mechanical stress, use a thicker high elasticity and flexible epoxy dome that will not crack or deform when in use.

2. Visual and Tactile Requirements (Color, Texture, Brand Identity, and Legibility)

The epoxy dome sticker is often the most visibly prominent branding element on a product. It should have an appearance that is consistent with brand visual identity and end-user expectation. High-gloss has an upscale glass-like appearance that can be applied to consumer products, electronics, and home decor. Matte or textured may be attractive on machinery or industrial equipment for reduced reflection and for optimum traction.

Color selection also supports readability. High-contrast large font color schemes, such as white over dark, provide logos and serial information readability from all directions. Tactile sense adds another value, well-crafted and strong domes with glossy finishes are better perceived by the user. When combined with metallic and embossed appearances, epoxy labels may enhance brand presentation without losing readable and consistent marking.

3. Installation and Surface Compatibility (Plastic, Metal, Coated, and Curved Surfaces)

Adhesion is promoted both by the adhesive character on the sticker and the surface condition of the target product. For high-tack acrylic adhesives to stick to smooth plastic or metal surfaces, there is strong and tough bonding. On coated, rough, or curved surfaces, more conformable adhesives with higher flowability allow for complete contact and prevention of edge lifting.

Always pre-clean the surface first prior to applying to remove dust, oil, or residues. Left out step can cause premature detachment. For curved or flexible object applications, such as bottles or equipment enclosures, use thinner stickers that will stretch without forming bubbles or wrinkles.

If painted or coated, the surface should be ensured to prevent the adhesive from chemically reacting with the coating, which may cause discoloration or degradation in bonding in the long run.

4. Material, Thickness, Coating, and Lifespan Evaluation

There are various base materials where epoxy dome stickers can be made, including PVC, PET, or metalized films. They have varying benefits. PVC is economic and flexible for short-term use or promotional use.

PET offers higher dimensional stability and better heat and chemical resistance, suitable for outdoor or industrial application. Metalized films offer a reflective finish for premium branding, which is widely used in luxury products or auto labels.

The epoxy dome thickness carries connotations in appearance and durability. Thicker domes will stabilize the 3D effect and improve impact resistance but will have longer curing time. Thin domes are more contemporary in appearance for modernist designs.

Protective coating or UV stabilizing prevents scratching, fading, or discoloration. When considering lifespan, don’t just consider the material endurance, but also consider the endurance of the adhesive to hold its bond in the expected environment. A well-designed sticker can survive many years without indication of degradation.

5. Budget and Cost-Effectiveness Considerations

Sacrificing quality to cost is required for small companies as well as mass manufacturers. Low-cost epoxy labels may look good at first but use inferior-quality resin and adhesives that cause discoloration, cracking, or peeling over time. This results in additional replacement costs and the risk of loss of brand image.

A first-time higher investment in high-quality materials may be less costly in the long term. High-quality epoxy compounds maintain color and clarity for decades with fewer maintenance and reprinting needs.

For mass orders, manufacturers can also price optimally by standardizing materials and mass producing, achieving cost without compromising quality. Budget by considering the whole product life cycle instead of sticker price. A durable, reliable epoxy dome label not only does brand image, but it also lowers the total cost of ownership.

The selection of the right epoxy dome sticker requires careful consideration of environmental conditions, surface compatibility, and design goals. In considering material strength, adhesive properties, and value, suppliers are able to balance durability, beauty, and affordability. Well-selected epoxy stickers not only protect the printed image but also serve as lasting representations of brand superiority and craftsmanship.

7. How to Evaluate the Capability, Qualification, and Experience of a Epoxy Dome Stickers Supplier?

The selection of effective and qualified supplier directly dictates meeting high-quality, performance-level, and delivery-based requirements of epoxy dome stickers. Technical capability of the supplier to manufacture, expertise, and industry-specific working experience directly impel product stability and reliability. The following-listed points will aptly allow you to gauge potential partners before you agree on bulk cooperation.

1. Assess Manufacturing Abilities

An efficient supplier would depict in-house production capacity in depth rather than outsourcing fundamental processes. This offers greater control over quality, lead times, and confidentiality.

While evaluating a supplier, note the following:

- Production Facilities: Check if they have cutting-edge printing machines, automated resin dispensers, and temperature-controlled curing environment. A temperature-controlled and dust-free workshop helps in clear, bubble-free epoxy domes.

- Equipment Maintenance and Upgrade: Regular calibration of coating and printing equipment demonstrates experienced process control.

- Ability to Customize: Determine if the supplier can produce special orders, such as variable data imprinting, color-matched domes, or serial-numbered graphics.

- Quality Control Systems: Ask about inspection stages, such as visual checks, adhesion tests, UV aging tests, and surface hardness verification. A reputable manufacturer will have extensive testing protocols and documentation of each batch.

Suppliers with strong technical foundation are better able to deliver consistent quality and production alterations efficiently according to project requirements.

2. Verify Quality Management and Certification

Certifications reflect a supplier’s commitment towards standardization and compliance to international manufacturing standards. Common certifications to look for are:

- ISO 9001: Ensures a formal quality management system in terms of continuous improvement and traceability.

- ISO 14001: Indicate environmental responsibility in material sourcing and waste disposal.

- RoHS and REACH Compliance: Ensures that the supplier’s material and adhesives do not contain restricted substances and are safe for global markets.

- UL or SGS Test Reports: Provide additional assurance of function, flame retardancy, and material safety.

In addition, ask if the supplier has internal checks or third-party checks to guarantee adherence to such standards. Certified suppliers will be able to maintain stable production quality, reduce the defect rate, and comply with regional export requirements.

3. Verify Experience and Industry Expertise

Experience plays an enormous role in the case of precision labeling and the use of resin. Those suppliers with some years of experience in the business usually know the subtleties of epoxy resin behavior, curing conditions, and surface compatibility.

Request to see samples of past work or use reference customers from sectors such as consumer electronics, automotive, promotional products, or industrial equipment. Having seen similar products, the supplier is able to expect and resolve potential pitfalls such as color shift under UV light or adhesive incompatibility on curved surfaces.

Also consider if the supplier offers design support and technical consulting. Seasoned manufacturers can guide you on selecting materials, dome thickness optimization, and printing techniques to improve appearance and functionality. Their input can reduce trial-and-error costs in development by a large margin.

4. Evaluate Scalability and Stability of Supply

The reliable producer needs to be able to produce small custom orders and large production runs without compromising quality. Ask about monthly capability, lead time, and backup plans for equipment or supply interruptions.

Producers with duplicate facilities or several lines can accommodate greater volumes better. Having internal consistency in raw material supply—epoxy resin, films, adhesives—also avoids quality changes batch to batch.

Stable supply chains and frequent delivery schedules are especially important for long-term projects or brand customers requiring frequent replenishment.

5. Test Communication and Customer Support

Technical proficiency is essential, but effective communication and fast service are just as important to a successful partnership. Try out the speed of the supplier in answering questions, whether they cover detailed quotations, and how well they explain technical points.

A professional supplier will actively offer suggestions, check artwork specifications, and offer status reports during the course of production. Following delivery, they can also offer post-sales support for application advice, reorders, or defect correction. Effective communication establishes confidence on both sides and reduces the likelihood of misunderstandings that can affect timelines or product quality.

Evaluating a supplier’s capability, certification, and expertise guarantees that you are aligning with a producer who will supply you with a consistent level of good-quality epoxy dome stickers. A good supplier aligns technical capabilities, quality control systems, and long-established industry experience with effective communication and prompt service.

Thoroughly verifying these areas before sealing any deal will enable businesses to minimize risk, ensure product consistency, and develop long-term partnership based on quality and confidence.

8. Epoxy stickers FAQs

Here are some frequently asked questions about epoxy stickers:

1) Are epoxy dome stickers waterproof?

Indeed, epoxy dome stickers are waterproof because epoxy resin is resistant to water. This characteristic earns them a good name in being used in applications where water and moisture protection is of utmost priority. The epoxy resin forms a water barrier seal on the sticker preventing water from penetration and reaching printed writing or photo.

Dome stickers of epoxy will normally be waterproof, depending also on water resistance level from other factors, including adhesive performance. Always consider consulting the manual from the maker to obtain the sticker working perfectly in your own use needs.

2) How long does epoxy on stickers last?

Shelf life of the epoxy would depend on such considerations as the kind of the epoxy, type of application, and conditions of use. Under usual circumstances, most of the epoxy products would last around 1-2 years provided they were stored properly. Best to store them in a dry, shaded region out of the sun to assist in maintaining their stability over time.

3) Do epoxy dome stickers break easily?

Epoxy is actually a tough and hard material much respected for its resistance to cracking, chipping, or breaking due to normal wear and tear. Properly cured, epoxy forms a very hard surface that can resist stresses and impacts of any nature.

However, it should be noted that epoxy stickers, just like any other substance, may be compromised in certain circumstances. Extremely high or low temperatures, knocks, or excessive stress might possibly compromise the strength of the epoxy and lead to possible cracking or chipping. In the spirit of preserving the long-term existence of epoxy stickers, the most advisable thing to do is handle them carefully and not put them under extreme conditions likely to destroy their long-term existence.

4) Can we epoxy over regular stickers?

When considering epoxy versus regular stickers, it’s critical to consider a few key factors for a successful installation.

First, adhesion quality in the sticker is a requirement. Adhesion should be high so that it would not be unable to withstand the weight of the epoxy and thereby peeling or lifting may be an issue.

Second, get the surface of the sticker clean, dry, and free of oils/debris. Dirt and oils will interfere with the epoxy adhesion and produce a lower strength bond.

If the surface and the sticker both have these conditions, then it is possible to apply epoxy over the sticker. Understand that the epoxy will imperceptibly alter the look of the sticker based on how heavy and transparent the sticker is.

5) How can we epoxy over regular stickers?

To use epoxy successfully over a sticker, mix the two halves of the epoxy as per the instructions from the manufacturer. Spread a small amount in the middle of the sticker and then spread it out using a brush or spatula without putting too much at one location. Let the epoxy cure based on the manufacturer’s instructions before using or handling the sticker. The process will put a protective covering over the sticker, and it will be stronger and more pleasing to look at.

6) Do epoxy dome stickers yellow?

Although epoxy stickers yellow with age, especially in the presence of sunlight or UV radiation, it is possible to slow down the process and in some instances return them to their original condition.

Yellowing can be prevented to a very large degree using a good UV radiation-resistant epoxy resin that can limit sunlight exposure. The stickers can also be stored in a dark cool location to avoid yellowing at a faster rate.

If you are able to notice yellowing on your stickers, clean them with soap and warm water gently to perhaps revive their look. But the severe yellowing, brittleness, or cracking may lead to having new ones. By following these measures, you can be able to enjoy the color intensity and longevity for your epoxy stickers.

9. Conclusion

Epoxy dome stickers are the best for anyone looking to add a decorative and hard component to their product. If you are personalizing your phone case, producing promotional items for your business, or constructing custom gifts, the stickers provide a luxurious finish and durability that endures, making them exceptional. With the knowledge of the specific properties and benefits of epoxy stickers, you are able to select the perfect one and design to fulfill your requirement, and release the diversity and creativity that the product can be.

Leave A Comment