Contemporary manufacturing and design have an ever-evolving world where customized graphic overlays are a vital element to improve both the functionality and aesthetic appeal of varied products. From consumer goods to industrial devices, these overlays are fundamental tools that provide essential information, improve user experience, and protect their interior components from being exposed.

No matter where your interest in graphic overlays lies – product development, manufacturing, or simply curiosity – this comprehensive guide is your go-to companion. It will take you on an in-depth journey into their materials, printing techniques, benefits, and applications.

1. What are Graphic Overlays?

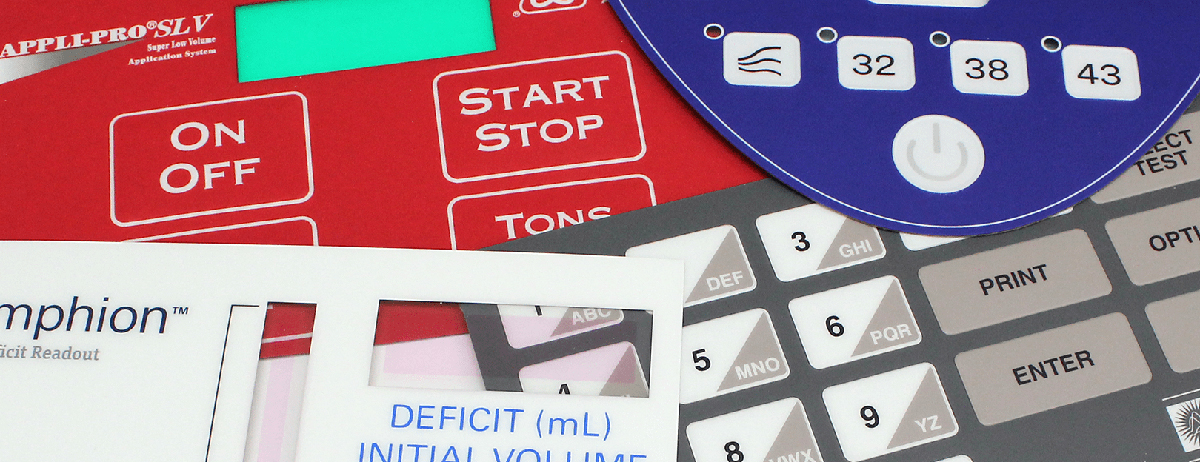

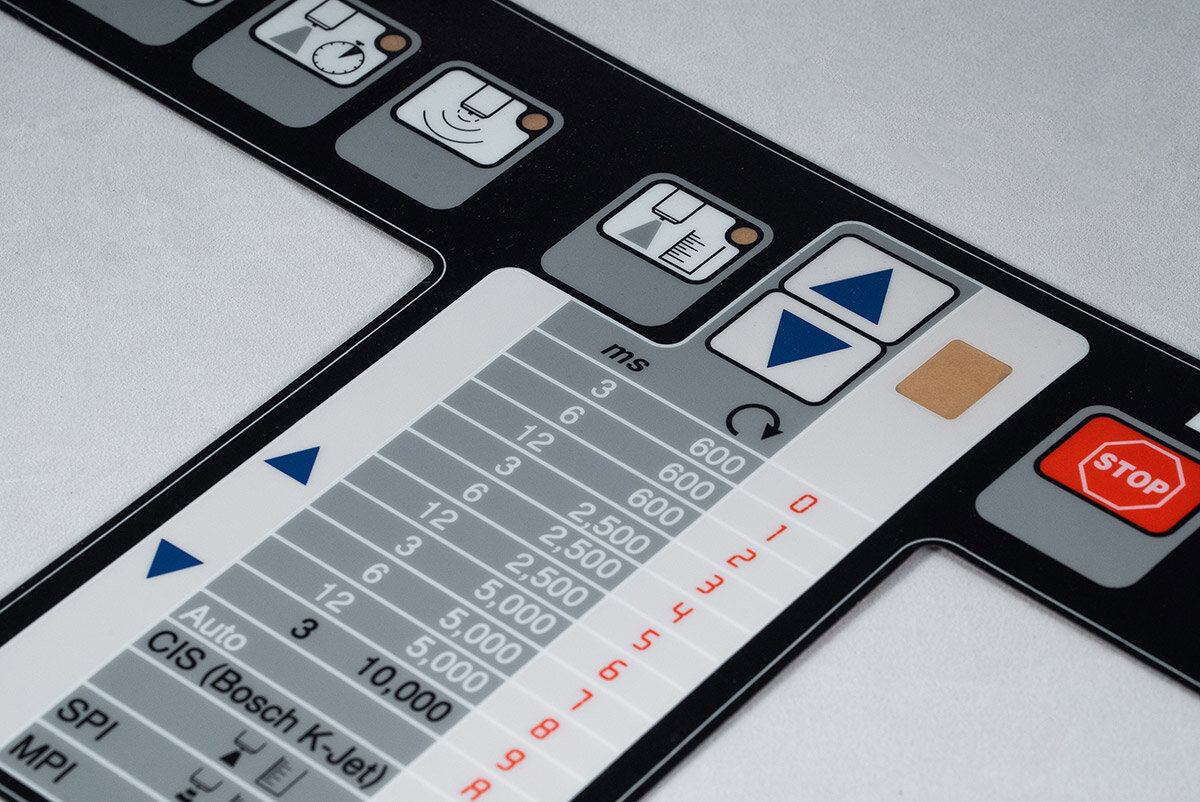

Graphic overlays are material layers covered in printed graphics, symbols, or text that are attached to products with precision. Acting as the gateway between user and device, graphic overlays serve both visually and tactilely to provide vital details like labels, instructions or brand identities to users.

They are usually mounted on control panels, touchscreens, membrane switches and other interactive surfaces. Graphic overlays play an essential part in user interaction and experience.

Custom graphic overlays can be designed to exact specifications, which allows them to remain resistant to anything from chemical exposure and UV radiation, moisture and extreme temperatures to chemical spillage and even immersion in chemicals. Moreover, the design-for-application overlays also offer unlimited color, texture and finish design possibilities for manufacturers – enabling them to design overlays that suit not just their brand image but also product functionality.

Graphic overlays are printed fragments of material, usually polycarbonate or polyester slightly hardened, placed on various equipment and products to indicate special use or convey essential information. Their functionality lies in features such as raised buttons that activate switches beneath the surface as well as windows displaying electronic information like LED displays.

Graphic overlays find use across an array of industries and devices, from healthcare devices and industrial machinery to electronic interfaces, telecommunications equipment, computers, robotic systems, industrial control panels, KVM devices, household appliances membrane switches modems and automotive control systems, among others.

Graphic overlay materials typically range in thickness from 5 to 20 mils, with polycarbonate being the go-to material and polyester not too far behind. Exceeding 20 mils presents some additional cutting difficulties that necessitate additional effort and expense in achieving your desired goal.

Graphic overlays ensure unparalleled durability and longevity by employing second-surface printing, an industry standard process used in their production. This technique involves printing ink directly on the reverse of clear material so the graphics can still be seen through its front or top, known as reverse printing. By employing this approach, all layers of the material shield the graphics, providing extra protection and prolonging its lifespan while the ink stays securely attached between its material layers and adhesive, further strengthening its resilience and guaranteeing lasting performance of your graphic overlay.

2. Key Functions of Graphic Overlays

Graphic overlays serve a dual purpose by both protecting underlying devices while elevating overall professionalism of end products. Tailoring overlays to specific needs is key when meeting diverse applications and environments – crafting graphic overlays for space exploration requires tolerating extreme temperatures and UV radiation exposure, for instance – but even though your products might not end up out there this article will highlight practical benefits from investing in high-quality graphic overlays for terrestrial uses.

1) Custom Controls

The primary motivation behind the majority of customers opting for a graphic overlay is the ability to effectively communicate vital information swiftly and clearly, especially crucial in controls to prevent user misunderstandings and errors. Consequently, the development of a graphic overlay transcends mere material selection, emphasizing the significance of meticulous design efforts. Our focus is on presenting all essential information in a succinct, unambiguous manner, delving into considerations such as color divisions and finishes to differentiate functions, and determining the optimal size for your company logo within the available space.

2) Industrial Use

In industrial settings, the significance of graphic overlays cannot be overstated, as inaccuracies in communication through the overlay can result in substantial losses during critical scenarios. While thorough staff training is crucial for operational confidence, the onus also lies on the graphic overlay designer to streamline and simplify the user experience. Industrial overlays must endure rigorous usage and potential chemical exposure. When placing your order, kindly indicate any specific requirements so we can tailor your overlay with resilient materials that align with your operational demands.

3) Medical and Research

Our graphic overlays are also made in an easy-to-clean format, bringing useful value to medical environments as a means of preventing harmful bacteria transmission across heavily touched surfaces. Production in antimicrobial materials ensures the prevention of future growth of harmful organisms between cleanings, further supporting the use for illness transmission prevention.

4) Marines

Overlays exposed to saltwater require special consideration when it comes to production. We offer durable etched nameplates fabricated with steel plates featuring intricate markings to withstand such environments; additionally we produce domed badges and polycarbonate labels tailored specifically for underwater use to meet all demands imposed by saltwater environments.

5) Customizing

Establishing a strong brand is crucial to building employee loyalty. That is why our bespoke graphic overlays are so vital for companies looking to increase visibility and unify their brand presence. We can design overlays to display critical information along with your logo for a cohesive brand image, with various finishes such as matte or gloss and ink options such as metallic ink allowing us to propel perceived product values even higher than before.

3. Types of Graphic Overlays

Graphic overlays come in various forms to fulfill specialized functional and aesthetic requirements, each designed for specific functions or aesthetic applications. Some of the more widely used types are described below:

1) Membrane Switch Overlays

Overlays for membrane switches provide a tactile interface when applied to the use of membrane switches, typically made of solid materials like polyester or polycarbonate, and ideal for repeated usage. Embossed buttons are even included by some membrane switch overlays for added tactility.

2) Touchscreen Overlays

Touchscreen overlays are used to encase and expand the touchscreens’ capabilities. Common ones are made of polycarbonate or acrylic material for improved optical quality and scratch resistance. Touchscreen overlays can also have the graphics or directions printed directly onto them to notify users.

3) Backlit Overlays

Backlit overlays are designed specifically to back-light, i.e., they work well where extreme visibility under conditions of low lighting is a priority. Applications are normal control panels, medical equipment and automotive dashboards – often made of transmitting polycarbonate or polyester materials.

4) Die-Cut Overlays

Die-cut overlays are individually molded covers cut to precise product dimensions. Often designed for button or switch fit, die-cut overlays are frequently employed where alignment is paramount.

5) Transparent Overlays

Transparent overlays are employed to protect underlying displays or graphics but allow the user to see through them, making these ideal for touchscreens, control panels and displays. They’re most often constructed using plastics such as polycarbonate or acrylic that offer higher optical clarity and scratch resistance – ideal materials for producing transparent overlays.

4. Advantages of Graphic Overlays

Graphic overlays have many benefits that make them a vital part of most products. Some of the main benefits of using graphic overlays are listed below:

1) Durability

Graphic overlays are made to endure tough environments, such as chemicals, water, UV light exposure and extreme temperatures – perfect for industrial, medical and outdoor use.

2) Customization

Graphic overlays offer manufacturers an incredible amount of design flexibility. Manufacturers can select materials, colors, textures and finishes to produce an overlay that complements their brand or product requirements perfectly.

3) Aesthetic Appeal

Custom graphic overlays can add a design element to a product by providing bright colors, texture, and finish that can further enhance consumer interest in your product. They can help in improving consumer perception of perceived value of your product while enhancing its attractiveness among potential buyers.

4) Protection

Graphic overlays are employed to protect underlying elements such as membrane switches or touchscreens from the environment in the form of moisture, dust, and chemicals. This provides added defense from potential harm.

5) Tactile Feedback

Many graphic overlays feature embossed buttons or other tactile features to enhance user experience by offering physical feedback when pressed.

6) Cost-Effective

Graphic overlays are an inexpensive way of adding functionality and appearance to products without spending capital on costly tooling or manufacturing processes.

5. Disadvantages of Graphic Overlays

Although graphic overlays provide many advantages, there are probably also some risks involved that need to be taken into account:

1) Limited Flexibility

Unfortunately, certain materials used in graphic overlays, like acrylic, may be rigid and therefore may not be appropriate for applications requiring movability.

2) Wear and Tear

Over time, graphic overlays may become worn and scratched from use, particularly those used in high traffic applications. Although durable materials can help mitigate wear-and-tear, replacement might still be necessary periodically.

3) Cost for Small Runs

When producing graphic overlays in small production runs, their costs can increase due to additional tooling, printing and finishing processes required.

4) Complexity in Design

Designing a custom graphic overlay can be an intricate process, especially when including features like embossing, backlighting and die-cutting into its design. This can add both time and costs to the production process.

6. Common Materials of Graphic Overlays

Graphic overlays serve as the face of your product, shaping user interactions with devices. As part of user interface design, overlays provide clear instructions on device use. Customizable to meet specific requirements and environments, these graphic overlays come with various material options that can help meet those demands. Selecting the best material type may seem like an intimidating task; here we present an exhaustive overview of popular options to aid your decision-making process.

(1) Polycarbonate (PC)

For applications where aesthetics play an integral part, polycarbonate graphic overlays are an obvious choice. While polyester may offer superior chemical and mechanical properties, polycarbonate offers greater customization possibilities due to its flexibility.

Polycarbonate overlays come with various thickness options and are easy to manipulate through die-cutting, embossing and thermoforming processes. Polycarbonate mimics a large portion of the advantage in glass products like UV resistance and glossy finishes at lower weight and expense.

Polycarbonate is easily scratched and lacks the chemical resistance of polyester; therefore, it’s not ideal for heavy use or applications with greater chemical exposure hazards.

- Advantages: PVC is printable, has great impact resistance, is chemically resistant, and has UV resistance.

- Disadvantages: Without hard coating protection, it may be susceptible to scratching.

(2) Polyester (PET)

Polyester (PET) stands out as an outstanding polymer-based overlay material, known for its exceptional resilience and resilience. With most favorable mechanical and chemical properties, allowing it to resist numerous types of harsh chemical substances and environmental attackers.

Polyester’s chemical resistance makes it a very good choice for equipment that gets in contact with potential cleaning chemicals and spills accidentally, and most blends resist UV degradation, so they may be used in outdoor applications such as membrane switches and keyboards. Polyester overlays may even be enhanced by antimicrobial coatings to ensure sanitary environments like cleanrooms and medical/pharmaceutical laboratories.

Polyester’s chemical and mechanical stability allows polyester graphic overlays to withstand extreme temperature and abrasion very easily, thus making the polyester graphic overlay very durable along with longer actuation life over polymer-based overlay materials.

- Strengths: Excellent chemical resistance, excellent durability and flexibility along with extreme temperature resistance are some of the many advantages offered by our material.

- Weaknesses: Relatively less impact resistant when compared to polycarbonate.

(3) Acrylic

Acrylic is usually used on overlays or where there is a high demand for optical clarity. Acrylic is hard plastic with outstanding resistance to weathering and UV light and, as such, can be used outdoors. Acrylic is, however, not as flexible as polycarbonate and polyester and cannot thus be used where flexibility is required.

- Strengths: High optical clarity, weatherability, and resistance to UV light.

- Weaknesses: Brittle, not as impact-resistant as polycarbonate and polyester.

(4) Vinyl

Vinyl overlays are also extremely valued due to being highly flexible, even above that of the majority of other available materials on the market. Vinyl is highly malleable, therefore, so easily it gets deformed and shaped according to every type of irregular surface with the least effort.

Cost-wise, vinyl provides a lower-priced option than polyester and polycarbonate overlays, thus making it the most suitable for big orders. It should be noted that while vinyl is lower in price, it is less resistant than others and only has average abrasion, weather, and chemical resistance. Vinyl graphic overlays are ideal to be used in less stressful environments where gloss, matte, or clear finishes are needed.

- Advantages: Flexible, cost-effective, good printability.

- Disadvantages: Not very long-lasting, will fade and deteriorate with time.

(5) Silicone

Silicone is a material that is used for different purposes where high-temperature resistance and flexibility are the main requirements. Its biocompatibility and high-temperature resistance have made it the leading material in medical and industrial applications.

- Advantages: High heat resistance, flexible, biocompatible.

- Disadvantages: More expensive than other materials, poor printability.

(6) PVC

Polyvinyl chloride (PVC) offers a good balance between durability and appearance, between that of polyester and vinyl. Though PVC will lack the strength of polyester, texture capability makes it more resistant to abrasion in moderately abusive conditions, making it an acceptable choice for specific industrial equipment applications.

The PVC graphic overlays benefit from being versatile in their ability to accept textures, finishes, and color schemes in a broad spectrum. Being a material of medium properties, PVC becomes the most cost-effective alternative in switches and keyboards of goods that have an average to limited lifespan expectancy.

- Advantages: Economical, printability is satisfactory, moderate durability.

- Disadvantages: Short lifespan, Moderate weather resistance.

7. Ink Decisions of Graphic Overlays

When selecting inks for graphic overlays, the choice between screen inks and digital inks is crucial in achieving the desired effect. The following is the description of the characteristics of each:

(1) Screen Inks

- Ideal for use outdoors, having improved fade resistance with a heavier ink film.

- Ideal for overlays that must be opaque to fill in base items like holes or other printing.

(2) Digital Inks

- No extra art charges.

- Offers low-cost unlimited copy alterations because electronic printing dispenses with plates or screens.

- Offers unlimited colors, complicated graphics, and complete design versatility.

- Offers correct color registration with no trap or fade-out issues.

- Permits serialization, serial numbering, barcoding, and QR coding.

- Offers high resolution, complicated detail, smooth gradient, subtle vignettes, and full-color process options.

8. Adhesive Decisions of Graphic Overlays

The choice of the adhesive for your graphic overlay is a very critical decision that defines the product’s durability, performance, and customer satisfaction to a great extent. Let us go through the critical considerations for the choice of the right adhesive for your graphic overlays to deliver the best performance in your target application.

(1) Durability

The adhesive for the graphic overlay of your choice should be tough enough to withstand the alternate hot and cold, moisture and the UV exposure that the environment may bring. If you choose a strong adhesive your overlay will not only last longer but will also look good even under extreme conditions.

(2) Functionality

The adhesive on the graphic overlay should be strong but at the same time, it should be easy for the user to remove and apply again if it is necessary. A good adhesive not only provides the overlay with a firm bond but also makes the overlay very user-friendly by providing seamless functionality thus supporting the overall user experience.

(3) Aesthetics

Other than its functional role of performance, the selection of adhesive has a great deal to play in determining the look of your graphic overlay. Applying a good quality transparent or color-matched adhesive can make a big difference in presenting your product with a smooth, seamless appearance that greatly improves its overall aesthetic appeal.

(4) Customization

Various adhesives offer varying degrees of customization options. Some adhesives offer repositionability in use, while others offer matte or gloss finish options. Selecting an effective adhesive offers you the ability to customize the appearance and feel of your graphic overlay to the precise specifications of your own customized design.

(5) Longevity

The right choice of adhesive can be the determining factor in the life of the graphic overlay. Employing an adhesive that can resist impact from wear and tear, chemical, and scratch will help maintain the quality and clarity of your overlay over long periods of use.

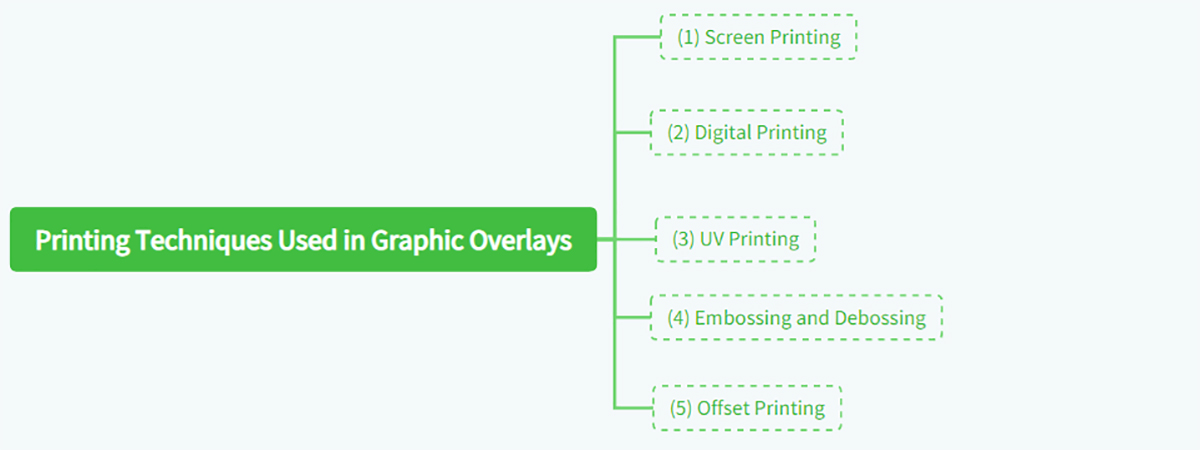

9. Printing Techniques Used in Graphic Overlays

The graphic overlay printing process plays a critical role in determining the end quality, strength, and appearance of the product. Every method has its strengths and weaknesses in every stage of the manufacturing process like high-resolution prints, color constancy, and strength. Some of the printing processes, which are considered to be the most common ones, that are used for graphic overlays, are mentioned below: The process of screen printing involves the use of a mesh screen to direct the ink onto the surface of the overlay material, thus achieving a high quantity and economical production with the required accuracy and consistency.

(1) Screen Printing

Printing application by screen is one of the main techniques for making graphic overlays. This method is the most economical way to make in bulk labels and graphic overlays on polycarbonate or PET substrates. The screen printing method involves the use of a mesh screen through which ink is pushed onto the surface of the overlay material, thus creating a high-volume and economical production with the required accuracy and consistency.

Screen printing is suitable for making deep and vivid colors, and it is highly resistant to wear and tear. This characteristic is certainly advantageous for overlays that will be placed in harsh environments. Despite being more capital-intensive, screen printing is less so than digital printing. For each color showing up in the print, an individual screen and screen positive will be needed. Additionally, each color needs one-on-one setup during printing and color-matching procedures.

Because of the increased setup fees, screen printing will most often cost more than digital printing if your run is under 100 units. Your actual break-even point where screen printing is cheaper than digital printing will depend upon size, complexity, and amount of colors required for your overlay or label.

- Advantages: Highly durable, full-color rich, good for big runs.

- Disadvantages: Limited color gamut, unsuitable for intricate designs.

(2) Digital Printing

Digital printing is a newer process that enables high-resolution, full-color printing in situ on the overlay material. Digital printing is a good production process for intricate designs with gradient effects, extensive color scales, or when production runs are relatively small.

The process is ideally suited to create intricate designs, gradients, and photo images. Digital printing is also a suitable process to create a prototype of a graphic overlay without investing heavily in tooling or setup charges. Digital printing also saves money when making small runs, as the screens or plates do not need to be set up.

- Advantages: High image quality, color printability, good for detailed images, cheap for short runs.

- Disadvantages: Less resistant to wear than screen printing, especially harsh conditions.

(3) UV Printing

UV printing is a computer-to-plate technology whereby ultraviolet light cures the ink once it has been printed onto the overlay material. This leaves an incredibly hard and scratch-resistant finish, perfect for overlays that are subject to wear and tear. Gloss, matte, and texture finishes and other than white color can also be attained through UV printing.

- Advantages: Durable, scratch resistant, durable and comes in many colors and finishes.

- Disadvantages: More expensive than standard digital printing.

(4) Embossing and Debossing

Embossing and debossing are techniques to form raised or depressed areas on the face of the overlay. The techniques can be used to provide the buttons with more tactile feel or to gain an attractive design. Embossing elevates the face while debossing creates an impression.

- Advantages: Enhances tactile response, and improves appearance.

- Disadvantages: Raises production cost and complexity.

(5) Offset Printing

Offset printing or lithography is widely used in high-precision printing, especially in graphic overlays.

- Advantages: Provides excellent image definition and color uniformity. Presents a wide range of color shifts. Suitable for bulk operations.

- Disadvantages: High set-up cost, Longer lead time, Low flexibility, Requires smooth surfaces.

10. Applications of Graphic Overlays

Graphic overlays are used in numerous various industries and applications. Some of the most common applications for graphic overlays include the following:

1) Medical Devices

Graphic overlays can be utilized in medical devices that are commonly used to provide labels, instructions, and control panels. Overlays are generally made of chemical- and moisture-resistant materials so that they will not be damaged during the sterilization procedure.

2) Consumer Electronics

In consumer electronics, graphic overlays add to the appearance and feel of the devices and offer user interfaces to buttons and touchscreens. Graphical overlays typically comprise high optical clarity, scratch-resistant material.

3) Industrial Equipment

Graphic overlays are also a part of industrial equipment that ranks to show labels, give control and instructions. Most often overlays are made of materials that can endure the severe conditions, including chemicals, water, and heat.

4) Automotive

Overlay fading or discoloration can happen if they are subjected to UV light or harsh chemicals, so to be on the safe side, pick the materials and printing methods that are designed for UV and chemical resistance.

5) Appliances

Eventually, graphic overlays will get scratched and worn off like any other thing with normal use over time, more so if situated in places that are high traffic. If you want to keep them for a longer time and make their lifespan even longer, then go for materials that have scratch-resistant coatings or use protective films wherever.

11. Graphic Overlays Troubleshooting

Though good design and appropriate application, graphic overlays sometimes encounter issues. Some common issues and the way they can be fixed are illustrated below:

1) Peeling or Lifting

If your overlay is peeling or lifting off from the surface, it might happen due to poor surface preparation or using a wrong adhesive. It is recommended to first clean and dry the area to be overlaid, then select an adhesive according to the materials and the environment.

2) Bubbles or Wrinkles

Bubbles or wrinkles may form when an overlay is not applied evenly or air becomes trapped during application, so to prevent this use a roller or other tool that applies even pressure across its surface. To do so successfully.

3) Fading or Discoloration

Overlay fading or discoloration can happen if they are subjected to UV light or harsh chemicals, so to be on the safe side, pick the materials and printing methods that are designed for UV and chemical resistance.

4) Scratches or Wear

Eventually, graphic overlays will get scratched and worn off like any other thing with normal use over time, more so if situated in places that are high traffic. If you want to keep them for a longer time and make their lifespan even longer, then go for materials that have scratch-resistant coatings or use protective films wherever.

12. Durability & Performance of Graphic Overlays

Customers often ask, “How long will it last?” The answer depends on the materials, environment, and usage frequency—but here’s what you can expect:

- Lifespan: Typically 1 to 3 million actuations or 3–7 years of outdoor use.

- Chemical Resistance: PET withstands alcohol, cleaning agents, and oils.

- Scratch & Abrasion Resistance: Hard-coated films maintain clarity over time.

- Temperature Range: -20°C to +80°C for most industrial-grade overlays.

- UV Stability: UV-cured inks prevent fading in outdoor or high-light applications.

For the longest lifespan, request overlays with UV-cured inks and hard-coated PET films.

13. Maintain Tips for Graphic Overlays

Proper usage of graphic overlays is crucial to their functionality and longevity, and therefore below are some tips on proper usage of overlays:

- Before one applies an overlay, the surface must be properly cleaned to flush out dirt, oil, and other impurities, including dust. This ensures that there is a strong bond between the surface and overlay.

- Use an Adhesive That Can Fulfill Both Demands: Select an adhesive that can fulfill both overlay material and the surface on which it will be mounted, such as exposure to moisture or high temperature. There are adhesives that are engineered to fulfill special environments such as exposure to high temperature or moisture.

- Carefully Align: Prior to applying the overlay, make sure that it is centered properly on the surface. Once adhesive comes in contact with it, repositioning may become difficult without damaging its integrity.

- After applying an overlay, roll or use another tool with uniform pressure across its surface to form a strong bond and prevent air bubbles from forming. This will give an airtight seal as well as help in preventing air pockets from forming in between layers.

Let Adhesive Cure: Some adhesives require time to set before they can reach their maximum bonding strength. Always follow manufacturer’s instructions regarding curing timeframe.

If you want to source custom graphic overlays from a Chinese manufacturer for touch screens, appliances, or control panels, partner with a supplier specializing in custom printed overlays.

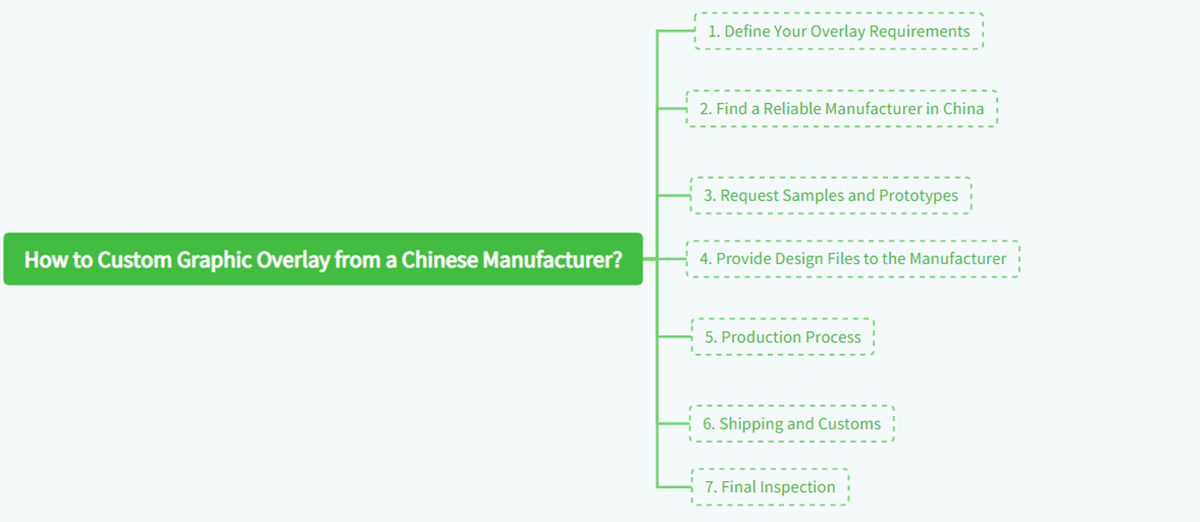

14. How to Customize a Graphic Overlay Manufacturer from China?

The following are the steps.

1. Define Your Overlay Requirements

Before approaching manufacturers for quotes on overlay solutions, it’s crucial to clearly outline your specifications:

Dimensions & Shape: Determine the dimensions and shape of your overlay. Material: Select an appropriate material such as Polycarbonate (PC), which is durable enough for electronic interfaces, or Polyester (PET), often utilized because of its flexibility and affordability.

Acrylic: Ideal for rigid overlays.

Graphic Design: When designing graphic overlays, provide designs for logos, icons, text and colors – either vector-based (e.g. AI/SVG) or raster designs (PNG/JPG).

Features: When considering additional features for an overlay – consider features such as:

- Backlighting: Determines whether your overlay will feature illuminated areas such as buttons or logos.

- Texturing: Provide tactile feedback through matte or glossy textures or embossed buttons by means such as matte finishes (matte or gloss) or embossed buttons for tactile feedback. Adhesive Type (e.g. adhesive backing, magnetic, etc).

2. Find a Reliable Manufacturer in China

To successfully produce custom graphic overlays, it is necessary to find a reliable manufacturer in China who specializes in this production type. There are various means available to find such manufacturers:

- Alibaba or AliExpress: These platforms are great ways to source manufacturers and suppliers. Simply search “custom graphic overlays”, “membrane switches” or “plastic overlays” to locate companies.

- Trade Shows and Sourcing Fairs can help you identify potential manufacturers, as can reviewing trade fairs like Canton Fair or China Sourcing Fair.

- B2B Platforms like Made-in-China.com or Global Sources also showcase custom graphic overlay manufacturers.

- Industry Directories: To search industry directories or suppliers specialized in electronics or custom printing.

3. Request Samples and Prototypes

Before placing any large order, it makes sense to request samples or prototypes as a way of ensuring the manufacturer can provide your specified quality.

- Order Samples: When you have your list of probable suppliers, order samples of custom graphic overlays so that you may assess the quality of material, print quality and the accuracy of your design.

- Prototype Testing: If an overlay is part of a larger product (for instance a device interface), test its prototype to ensure it functions as intended – such as testing button presses, touch sensitivity and backlighting.

- Review and Adjust: Make sure that the design, colors, textures, and print quality meet your standards before reviewing with the manufacturer for revisions. When finished, provide Design Files directly to them.

4. Provide Design Files to the Manufacturer

Once you are pleased with the sample, provide your manufacturer with your final design files – typically:

- Vector Files: Popular file formats are AI, SVG or EPS for vector graphics that scale without loss in quality. Raster Files (e.g. PNG and JPG) must have sufficient resolution to ensure proper printing results.

- Specifications: Provide detailed color instructions (Pantone colors or CMYK/RGB), special features (e.g. embossed buttons, backlighted areas) and material specifications.

Some manufacturers also provide design services or can assist you in refining your designs, so enquire if necessary.

5. Production Process

Once an order has been confirmed and placed, the production process typically entails five steps:

- Printing: Your design will be printed onto an overlay material using methods such as screen printing, UV printing or digital printing, depending on its materials and your design.

- Cutting: Once printed onto the material, the overlay will be cut using either laser cutting or die cutting techniques until its desired size and shape have been reached.

- Functional Features Will be Added as Necessary: Any necessary features such as backlighting, tactile buttons or embossed areas will be implemented if required.

- Adhesive Backing will be applied if an overlay needs to be adhered onto an object surface.

- Quality Assurance: Manufacturers usually conduct rigorous quality checks at different stages to ensure the final product satisfies your specifications.

6. Shipping and Customs

- Once production has concluded, your manufacturer will ship your order. Arrangements for shipping may either be managed directly by yourself or outsourced to them for management.

- Customs Clearance: Be ready for any customs duties or taxes applicable to the country in which you import from. Your manufacturer may assist with the customs clearance process or provide necessary documents.

7. Final Inspection

Once your shipment arrives, conduct a final inspection to assess its quality and accuracy. Check for defects such as incorrect colors, poor print quality or alignment issues to make sure everything meets your standards.

Reliable overlays don’t happen by chance, they’re the result of strict quality checks.

Most manufacturers (including us) perform these tests before shipment:

- Color Accuracy Test – Ensuring perfect color consistency with Pantone standards.

- Adhesion Test (Peel Test) – Verifies bonding strength between layers.

- UV Aging Test – Simulates long-term outdoor exposure.

- Abrasion & Scratch Test – Confirms surface durability.

- Dimensional Check – Ensures every cutout and edge matches the design drawing.

15. Tips for Working with a Chinese Manufacturer

- Communication: When communicating with Chinese manufacturers, be clear and precise to prevent miscommunication and misunderstandings. Where possible, provide technical drawings and design specifications as part of your dialogue.

- Language Barrier: Not all manufacturers speak English fluently; using simpler language or working with a translator may help.

- Minimum Order Quantities (MOQs): Most manufacturers require minimum orders quantities; make sure you meet them or negotiate.

- Payment Terms: Be aware of payment terms, which are often 30% upfront and 70% upon completion or before shipment.

16. Recommend Manufacturers in China

- MSTR: Well-known for providing superior overlays and membrane switches with custom designs.

- Shenzhen Qianxun Technology Co. Ltd: Provides customized membrane switches, overlays and touchscreens.

- Shenzhen Honghua Membrane Switch Co., Ltd: Provides custom graphic overlays design and production for various industries.

By following these steps, you can create and order custom graphic overlays from a Chinese manufacturer for devices, products or even marketing and branding purposes.

17. Custom Graphic Overlays FAQs

Here are some commonly asked questions regarding custom graphic overlays:

1) What is an average lifespan of a custom graphic overlay?

The lifespan of custom graphic overlays is depending on its material, print process and conditions; typically strong polycarbonate or polyester-made overlays should last several years in harsh environments.

2) Are custom graphic overlays backlit?

Custom graphic overlays can be designed with backlight capability, which is most suitable for applications where visibility is required in low light conditions such as control panels, medical devices and automotive dashboards. Backlit options are commonly applied on control panels, medical devices and dashboards.

3) Are custom graphic overlays waterproof?

Most custom graphic overlays are constructed with waterproof materials like polyester and polycarbonate that will withstand exposure to water or humidity, such as polyester film.

4) May I install a custom graphic overlay myself?

Yes, hand-applied custom graphic overlays can be done but to achieve the ultimate bond and to avoid bubble or wrinkle formation it is essential that proper application techniques be followed. Make sure that the surface is dry and free of dust and dirt prior to initiating application by roller to apply uniform pressure to the overlay.

5) How is screen printing different from digital printing for graphic overlays?

Screen printing is a traditional process where the ink is forced through a mesh screen, resulting in very strong, high-color intensity color with high strength. Digital printing permits higher-resolution full-color print capability more appropriate to intricate designs; however, digital is generally not as resilient in harsh settings as a screen.

18. Conclusion

Graphic overlays play a vital role in product design by enhancing both aesthetics and usability. They protect the underlying components while improving user interaction, making products more intuitive and durable.

By understanding materials, printing methods, and design details, you can make informed choices that elevate both performance and visual appeal. High-quality graphic overlays ultimately contribute to a more professional and refined product experience.

Leave A Comment