Having observed a glowing, shimmering sheen that adorns certain labels and stickers, you may have stood face to face with a gorgeous phenomenon where the material glows in a selection of colors as light falls on it. Fascinated by hologram sticker composition?

Do not worry, we will learn why holographic stickers matter by analyzing their nature and primary uses. Let us begin doing this by learning the primary components of hologram stickers and their primary uses.

1. What is a Hologram Sticker?

So what in the world is a hologram sticker, you ask? A hologram sticker, coincidentally, is an unusual type of sticker that produces a three-dimensional image upon the surface of two dimensions. Unlike stickers that are standard, hologram stickers produce an effect of optical depth by diffraction of light.

These enchanted stickers don’t exist merely for aesthetic purposes; they serve several practical applications within a variety of industries. Having set the groundwork, let us proceed to the staggering uses of hologram stickers.

2. What are the Design Benefits of Using Holographic Stickers?

The benefits of choosing holographic stickers are self-evident. Besides the fact that they present an engaging and interactive visual appeal, they can also make your products noticed wherever they are located.

You can achieve depth and movement in your design by using the reflective surface. For one-time use, limited edition, or daily branding, hologram stickers can be utilized to amaze the mind and create a splash.

- Anti-Counterfeiting: Hologram sticker making is some intricate steps and designing, so it is extremely unlikely to be counterfeited, thereby giving a ridiculously high level of authenticity against counterfeiting.

- Brand Upgrade: The glossy, shiny finish of hologram stickers gives the product an elegant look, elevating the brand image as a whole.

- Flexibility: Hologram stickers can be customized in any form, shape, size, and color, and therefore are suitable for an amazing array of uses.

Reliability: Since they are manufactured from good-quality material, hologram stickers are resistant to damage, and therefore they function and remain undamaged for a longer period of time. - Tamper Evident: The majority of hologram stickers have been made tamper-evident, leaving behind a visible mark or breaking when attempted to be peeled off.

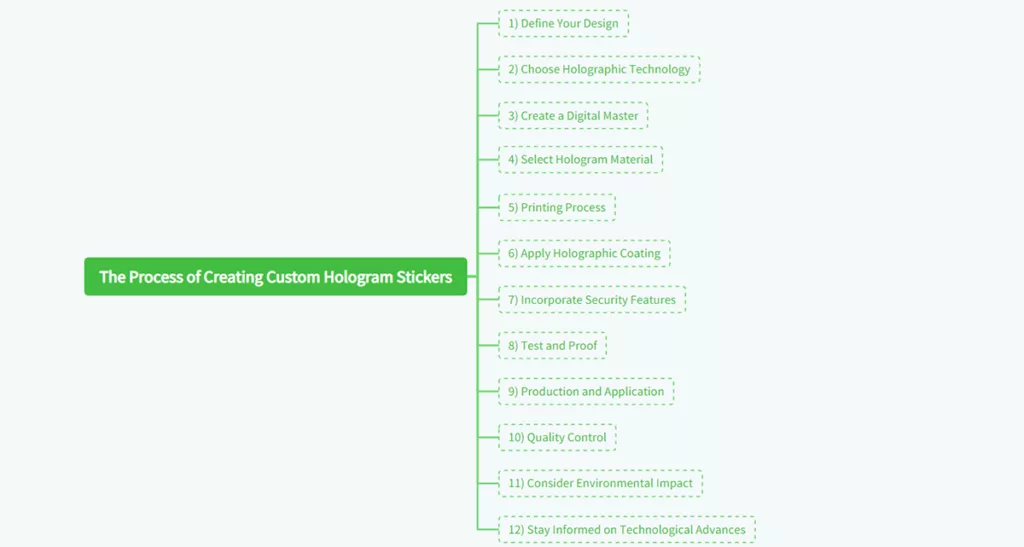

3. The Custom Hologram Sticker Creation Process

Creating custom hologram stickers is a time-consuming and artistic endeavor that takes time, effort, and expertise. It’s a combination of art and technology such that each step goes into creating beautiful holographic labels. Read this step-by-step guide to start producing your own enchanting hologram stickers.

1) Define Your Design

Begin with a fantasy of the hologram sticker design. Consider its application—whether for brand authentication, product embellishment, or decorative purposes.

2) Choose Holographic Technology

There exist different holographic technologies with different visual effects. Choose a rainbow-like effect, a 3D illusion, or a kinetic movement within the hologram. Rainbow holography is one of the most favored techniques, along with dot matrix holography and laser transmission holography.

3) Create a Digital Master

Scan your artwork with the assistance of computer illustration software like Adobe Illustrator or CorelDRAW. Make it high-resolution and hologram print-friendly. The digital copy will serve as the blueprint of your hologram image.

4) Select Hologram Material

Select an appropriate holographic material for your application and intended use. Holographic material is available in numerous forms such as foils, films, and labels. Consider adhesion, strength, and compatibility with your target printing technology.

5) Printing Process

Some printing processes can be employed for holographic printing such as embossing, lithography, and digital printing.Use a process that suits your budget and design capability. Embossing, for instance, is ideal in producing the raised tactile holographic appearance.

6) Apply Holographic Coating

Improve the holographic look and seal the sticker by applying a holographic coating on the printed face. The holographic, transparent coating hardens the sticker along with improving the look.

7) Incorporate Security Features

For security purposes, consider integrating features like micro text, hidden images, or serialized numbers into your hologram sticker. These elements enhance security by increasing the complexity of replication.

8) Test and Proof

Test hologram stickers in advance of mass production so that design is correctly reproducible holographically. Check color fidelity, image resolution, and general visual appeal. Make the necessary adjustments based on tests.

9) Production and Application

Upon approval of the proof, proceed with mass production. The holographic material is printed, laminated, and die-cut into individual stickers. The hologram stickers are now applied to your products, packages, or documents using adhesive backing.

10) Quality Control

Follow a strict quality control system to guarantee each hologram sticker is up to the required standard. Test for uniformity of holographic effects, good adhesion, and overall print quality in order to ensure the authenticity and integrity of your hologram stickers.

11) Consider Environmental Impact

Adopt environment-friendly methods of producing your hologram stickers from biodegradable or recyclable materials. Research reduced-environment-printing technologies in achieving sustainability goals.

12) Stay Current with Technology

Remain updated with ongoing technologies in holography in an effort to include the latest features in your next hologram sticker releases. This ongoing awareness ensures that your holographic labels are current and functional.

4. Uses of Hologram Stickers Across Sectors

Hologram stickers are not only for beautification but also multifunctional brand protection, authentication, and communication devices. Their light reflectable properties in various colors and three-dimensional designs make them difficult to counterfeit, and their flexibility makes them applicable to various industries. The following sections present the most widespread applications, utilitarian purposes, and security purposes of holographic stickers.

1) Industry Applications

1. Consumer Electronics

Holographic stamps have widespread uses on electronic products such as mobile handsets, laptops, and peripherals for the purpose of strengthening authenticity and brand building. Organizations place holographic stamps on packets or the housing of devices to assure customers that the product is genuine and has undergone quality checks.

2. Pharmaceuticals and Healthcare

In the drug business, holographic labels serve as tamper-evident seals for medicinal bottles, blister packs, and medicinal devices. Because illegal drugs are extremely dangerous, hologram stickers containing distinctive designs or serial numbers help authenticate the product and ensure compliance.

3. Cosmetics and Personal Care

Holographic labels are employed by cosmetics and skincare organizations not only for their aesthetic appeal but also to protect luxury packaging against counterfeiting. A hologram can invoke a logo, present luxury visual texture, and serve as an authentication mark that ensures customers with original quality.

4. Government Documents and Certificates

The majority of government agencies use holographic emblems in identification cards, tax stamps, diplomas, and official certificates. The labels are anti-counterfeit and offer easy visual verification. The complex diffraction feature of the hologram cannot be achieved with standard printing, and thus it is an accepted security label.

5. Tickets, Events, and Collectibles

Concert tickets, sporting passes, and specialty items tend to include hologram stickers to authenticate legitimacy and avoid duplication by unauthorized means. The reflective color-changing effect also serves to further the collectible value and aesthetic beauty of the items.

6. Industrial and Automotive Equipment

In industrial use, hologram stickers identify genuine spare parts, safety-validated components, or maintenance records. They provide traceability and allow final users to identify genuine components from copies, which is essential for equipment safety and functioning.

2) Functional Labeling

Apart from looks, hologram stickers as functional identification are employed to merge information, branding, and technical performance. They can contain serial numbers, barcodes, QR codes, or microtext for machine readable tracing. Others integrate holographic and digital print technologies so that producers can encode batch numbers or warranty details directly onto the surface.

Functional holographic labels also improve user interaction. On product packs, they return light from different directions, causing a dynamic effect that increases shelf awareness. In this way, they serve both as an information supplier and a promoter, improving customer confidence at the point of sale.

For multi-channel distributors, holographic labels facilitate easier inventory management and supply chain monitoring. With serialized data, they allow each product to be traced back from the factory to the end user, with increased transparency and accountability.

3) Anti-Counterfeiting and Security Applications

The most significant use of hologram stickers is in anti-counterfeiting protection. Each hologram design is created through complex optical mastering that requires specialized equipment and cannot be reproduced by standard printing or photocopying methods.

1. Security Features

New hologram stickers may feature multiple safeguard technologies, such as:

- Microtext or nanostructured patterns that can only be seen under a microscope

- Concealed images or color shifts when observed at precise angles

- Laser-engraved serial numbers or variable information unique to each batch

- Tamper-evident adhesive strips that will leave a pattern or residue when removed

The layered security options make copying nearly impossible, providing firm protection against counterfeiting.

2. Authentication and Verification

Both consumers and brands benefit from hologram stickers as an easy-to-understand means of authenticity checking. Under illumination, the hologram shows color shifts and depth illusions which are impossible to replicate with full precision. Additionally, coupled with a QR code or a registration web page, the consumer can check the product on the internet, adding a digital validation level.

3. Supply Chain Security

In worldwide distribution channels, hologram stamps also play a vital role to prevent diversion and substitution. Each stamp can act as a guaranteed point of reference in the product history to help ensure only approved products make it to retailers and consumers. With the combination of holographic design and data management, companies achieve visual and digital security.

Hologram labels marry science, art, and security into a single small area. They imprint branding, communicate authenticity, and prevent counterfeiting in industries from electronics and pharmaceuticals to government identification and designer products. By discovering their use beyond intention, producers can design labels that are not only customer-interactive but also maintain product integrity throughout the supply chain.

5. What Colors Look Good on Holographic Stickers?

When selecting colors for holographic stickers, how they interact with the rainbow background is most important. Selecting active, vibrant colors is a success as they create a bright contrast to the active rainbow background, and your design bursts onto the scene with maximum impact. The bright colors ensure that your sticker design gets noticed and blinds the observer, even from afar.

On the other hand, light colors also possess beauty since they soften your stickers, making them look ethereal. The soft shades blend with the holographic material to create a soft and alluring effect that embodies the beauty of magic and lightheartedness in your design. This method is perfect for companies that want a dreamy or fine appearance that will attract their customers.

For creating an abrupt impression, dark colors prove to be most ideal. Dark colors form an overriding background from which the holographic elements look intensely bright on their contrast against, and as a result, a very startling effect is obtained. Dark colors provide the illusion of depth along with seriousness to the design so that it’s best suited to projecting sophistication and boldness that leaves a lasting impression.

6. Cost and Lifespan Evaluation of Holographic Stickers

In the selection of hologram stickers, lifespan and cost are complementary factors in determining brand protection strategy as well as long-term operating performance. Finding the balance between initial investment and durability guarantees firms make data-driven purchasing decisions rather than selecting the lowest initial price.

1) Initial Cost versus Long-Term Replacement Cost

When choosing hologram stickers, price and longevity are interdependent considerations that affect both brand security strategy and long-term business effectiveness. Realizing the trade-off between upfront investment and durability provides companies with fact-based buying decisions instead of merely selecting the lowest upfront cost.

The price of a hologram sticker initially relies on a number of factors like material quality, printing intricacy, security elements, and batch order. Plain decorative holograms with regular patterns are not very costly, but customized holograms with microtext, laser etching, or serial numbers need technical equipment and higher production accuracy, hence more costly.

But cheap sticker is not always most valuable. If the holographic film or adhesive is poor quality, it will degrade, peel, or lose reflectivity after a few months and needs constant replacement and reprinting. This incurs indirect costs such as labor, logistics, and quality complaints.

Conversely, high-grade hologram stickers preserve optical clarity and adhesion for several years, without repeated production and with uniform product presentation. Their cost of ownership over the course of time is often lower than that of the cheaper alternatives.

2) Factors Affecting Service Life

The duration a hologram sticker lasts is contingent on how it endures environmental stress as well as mechanical stress. Environmental factors such as temperature, humidity, ultraviolet radiation, and chemical contamination may cause adhesives to degrade and cause fading or delamination. Outdoor applications, for example, require UV-blocking substrates and weather-resistant overcoatings to preserve reflectivity.

Handling and surface conditions are also essential. Poor installation on greasy or dirty surfaces can result in air bubbles or partial peeling. Severe friction or bending can weaken the holographic layer and reduce aesthetic and security performance.

Service life could be further prolonged through the application of an oxidation inhibiting varnish or a protective laminate coating over the hologram design, along with protection against scratches. Where there is a need for tamper evidence or frequent handling, choice of an appropriate adhesive grade and surface finish ensures that the sticker will not degrade throughout the entire product life.

3) ROI Estimation: Durability versus Low-Cost Materials

Return on investment (ROI) for holographic labels should be quantified in terms of protection value, rather than unit price. A durable holographic label defends reputation, prevents counterfeiting, and enhances consumer trust, all of which translate to measurable business value.

When comparing, consider tangible and intangible returns. For example, if a costly hologram is 30 percent more costly but reduces threat of counterfeiting by 200 percent and enhances usage lifespan by 200 percent, the actual ROI is a far higher number. Reduced reprinting, reduced warranty claims, and increased brand reputation all help in saving money down the road.

Cheap materials, on the other hand, will be inexpensive in the short run but will lead to distorted images, failure of adhesion, or compromised security features. Once counterfeiters exploit poor holograms, brand recovery costs will readily overshadow any initial savings.

Therefore, for high-critical applications such as drugs, government licenses, or high-end consumer products, permanent, high-accuracy hologram use represents the maximum overall payoff. For promotional scenarios that last for brief periods or for temporary packaging, simpler hologram films may be enough provided that the circumstance is manageable.

An effective investment and lifespan plan ensures hologram stickers provide economic and protective benefits. Measuring interaction between initial investment, environmental performance, and long-term value allows producers to experience consistent security and frequent brand visibility. In most cases, emphasizing quality over immediate investment provides increased longevity, higher consumer confidence, and stronger return on investment.

7. Select Hologram Stickers Tips

Want to pick the most suitable hologram stickers for your company? Below are some tips that are indispensable to guide you in the correct direction:

1) Material

Holographic stickers consist of thin, flexible plastic sheets of films containing micro-embossed holographic pictures on plastic substrates like polyester (PET), PVC, and Oriented Polypropylene (OPP). Choose your selection of the material depending on your usage needs and application intended. Utilize scratch holograms for one-time application or instant holograms for quick application. Add a glossy finish to the stickers to make them more resilient to sun exposure and severe weather conditions.

2) Adhesive

Use holographic stickers with strong, self-adhesive properties for safe holding without harm to surfaces. Durable adhesive stickers give an extended presence, and they are the most ideal for most uses.

3) Size & Shape

Be careful about the size and shape of the stickers so that they perfectly fit your surfaces. With a range from 3x3cm to 30x30cm, there are several sizes to choose from, and pick the shape, i.e., rounded-corner, oval, or circles. Personalize the size and shape according to your own business requirements and upon which you will use the stickers.

4) Color & Style

Select colors and designs that are relevant to your brand image and message. Utilize logo colors for professional-styled stickers and research color combinations that suit your niche. Employ colors and designs that enhance the artistic effect you seek to convey in your work.

5) Price

Although not the only deciding factor, price is a consideration in your sticker selection process. Think in terms of budget, quality demands, and quantity needs when considering pricing options. Request sample stickers from printing companies to assess quality and ensure they meet your standards.

6) Quality

Be willing to pay for quality when choosing holographic stickers to guarantee that they suit your requirements. Place trial stickers to test for clarity, durability, and overall appearance before purchasing them. High-quality stickers with appealing aesthetics make a lasting impact on the audience.

7) Customization

Customization gives a personal feeling to your holographic stickers so that you can customize them based on your requirements. If you require logo stickers, promotional banners, or customized designs, professional print houses offer customization services to bring your imagination to life. Choose products that have good reviews and specifications that match your requirements for an easy selection process.

8. How to Cooperate with a Reliable Hologram Sticker Manufacturer?

Cooperation with a reliable hologram sticker maker is the prime requirement to achieve stable quality, guaranteed anti-counterfeiting performance, and smooth project delivery. A reliable manufacturing partner not only provides production but also contributes to design improvement, testing, and long-term brand protection. The following steps outline how to set up healthy and sustainable cooperation.

1. Clarify Project Requirements and Objectives

Start by defining the application of your hologram stickers. Are they to be used primarily for brand reinforcement, security authentication, or product tracking? The intent dictates different materials, visual look, and production methods.

Collect detailed specifications like sticker size, shape, surface finish, desired hologram effect, and level of security (e.g., serial numbering, inclusion of a QR code, or tamper-evidence). Clearly documented specifications allow the manufacturer to offer suitable materials and processes that match your plans.

2. Evaluate Technical Capacity and Qualifications

A genuine manufacturer should possess technical capability and qualification. Look for facilities with experience in optical mastering, embossing, laser etching, and creating holographic film.

Certifications such as ISO 9001 or ISO 14298 (security printing management) show standardized processes and controlled environments. Ask for sample reports or test reports on adhesion, UV resistance, and durability. Companies with a background of supplying into industries like pharmaceuticals, government, or electronics will likely have stronger quality control systems.

3. Ask for Samples and Pilot Test

Before mass production, order prototype samples or a small pilot batch. This allows you to check optical effects, bonding strength, and color consistency under real use conditions. Check that design matches final output, patterns are sharp, reflective, and free of blurring or misregistration.

If your design incorporates serialized holograms or variable information, make certain print quality and database management are well established. A cooperative manufacturer will aid in optimizing color, brightness, and complexity of patterns during this step to provide enhanced visual performance.

4. Discuss Material Options and Security Features

A qualified supplier will address differences among materials such as PET, PVC, or metalized film, as well as adhesive types for various surfaces. Describe available security options, including microtext, covert imagery, tamper-evident layers, or UV-visible codes. Each provides a further level of protection against counterfeiting and must be chosen in conjunction with your risk level and market segment.

Open communication about design confidentiality is also important. Ensure that the manufacturer has secure data handling and non-disclosure measures in place to protect proprietary artwork and master hologram plates.

5. Check Production Process, Lead Time, and Quality Standards

Establish firm production schedules and check each step, optical mastering, embossing, coating, cutting, inspection, and packaging. Ask for in-process quality testing, such as adhesion testing and color consistency measurement. Good manufacturers will use controlled cleanroom facilities for embossing and coating to prevent contamination or optical defects.

Schedule delivery expectations and build in flexibility to allow for testings and revisions. Long-term relations are facilitated with transparency on production capability and order scheduling.

6. Bargain on Price, Payment Terms, and Post-Sales Support

Cost matters, but pay attention to total value, not just the price per unit. A little more money can come with better film quality, higher-strength adhesives, and expert technical assistance.

Bargain payment terms and lead times that are compatible with your project schedule. Bargain warranty or replacement policies for defects.

Post-sales service should include guidelines for handling, storage, and application of hologram stickers. Responsible manufacturers will also provide continuous support for design improvement, reorders, or material enhancement.

7. Establish Long-Term Partnership and Communication

Once the initial project succeeds, maintain communication with the manufacturer. Monitor production feedback, performance records, and market trends closely to make adjustments to design or material specifications.

Forming a stable partnership encourages trust, facilitates faster turnaround for new designs, and ensures more stable prices. Good suppliers often prefer repeat business and can supply technical advice for new anti-counterfeiting solutions or new packaging concepts.

Collaborating with a hologram sticker manufacturer that produces quality products is not about placing an order. It is a partnership process that integrates design, security, production, and quality control. Through the process of explaining requirements, validating technical capability, testing samples, and transparent communication, businesses are able to establish strong partnerships that deliver enduring, visually appealing, and secure holographic labeling solutions.

9. Hologram Sticker FAQs

Following are some common FAQs about hologram stickers:

1) What is a hologram sticker, anyway?

A hologram sticker is a unique two-dimensional surface with a three-dimensional image through diffraction of light. It leaves an amazing visual impact, which creates a feeling of depth and makes it distinct from other stickers.

2) How do hologram stickers contribute to brand authentication?

Hologram stickers are a good tool to be used in brand authentication since they possess intricate patterns and optical features. These features are very hard to counterfeit for the imitations, thus assuring the genuineness of the branded product.

3) Can hologram stickers be tailored to a brand’s style?

In fact, the major advantage of hologram stickers is that they are highly customizable. Hologram photographs can be created by companies to resemble their own special design so their products stand out and appear branded.

4) What is the use of hologram stickers in packaging of products?

Hologram stickers add a glamour and sophistication flair to the packaging. The glittering visual effects not only contribute to the overall beauty of the packaging but also help in the brand recognition and building consumer trust.

5) How do hologram stickers enhance security measures?

Hologram stickers use tamper-evident technology that leaves traces of any attempt at tampering or removal, resulting in very noticeable marks. This makes them an economical but efficient means of introducing security into sensitive documents, IDs, and luxury items.

6) How are hologram stickers manufactured?

Hologram stickers are made with the assistance of contemporary 3D technology, since sophisticated patterns are printed or embossed onto holographic material. The incredible visual effects of hologram stickers are the result of this process.

7) What Kind of Material Is Used to Produce Hologram Stickers?

Special holographic pattern stickers are made from embossed vinyl film. Place the sticker against the light and observe it at different angles, and you will see the typical rainbow effect. Each sticker is embossed so that each replica produces the same effect all over, so not only does it shine with excellent brightness, but it does so in an extremely dazzling fashion.

10. Conclusion

Hologram stickers ultimately symbolize a combination of innovation, security, and beauty. As unique stickers, they are already making a significant contribution to brand safety, packaging re-design, and a general visual experience across various business fields. Due to their breathtaking optical effects and user-friendly design potential, hologram stickers are being employed as a successful and far-reaching tool that can be utilized by companies looking to combine style and substance. Trace the magic of hologram stickers to boost the visibility of your brand and amaze your audience to the maximum.

Leave A Comment