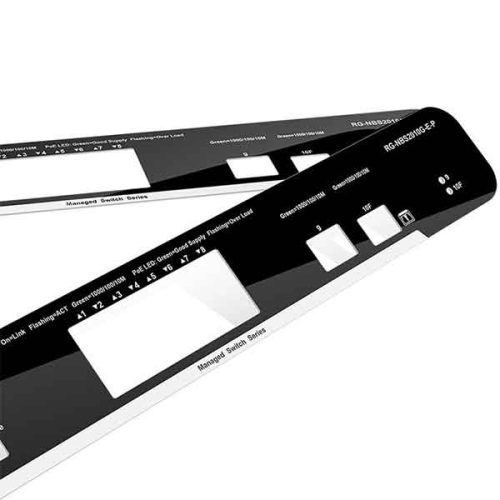

Metal Transfer Stickers are a fast and easy way to Enhance brand awareness. Apply to bottles, jars, boxes, packaging and more. Made from a durable material with a laminate that resists scratching, heat, water and sunlight.

- Durable and long-lasting adhesive properties.

- High-resolution printing for intricate designs and details.

- Versatile application on various metal surfaces.

- Resistant to water, UV rays, and harsh environments.

- Easy application process with minimal equipment requirements.