In-Mold Decoration Service

MSTR Printing provides high-quality In-Mold Decoration (IMD) service to ensure high-resolution, wear-resistant, and durable graphics on the plastic components. As it allows for complex and multi-colored designs, it can provide manufacturers with greater design flexibility and efficiency in production

Our IMD service creates aesthetically appealing and long-lasting decorative finishes for various industries, including automotive, consumer electronics, and home appliances. Now, MSTR Printing can produce more than 500,000 IMD/In-Mold Decoration parts every month.

Precision Die Cutting Service

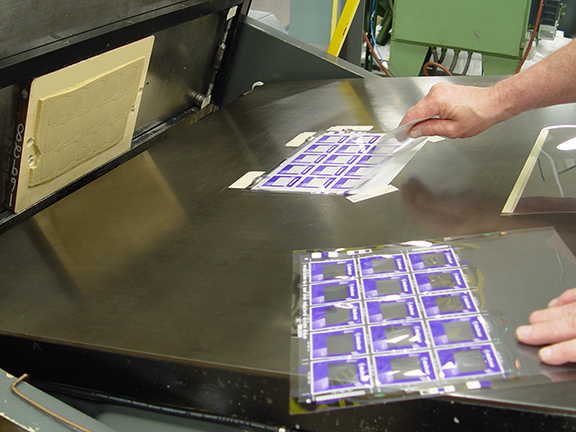

MSTR printing provides high-quality precision die-cutting service to custom printing solutions with a variety of materials, including fabrics, films, foils, foams, and other substrates with or without adhesive backings.

Different die-cutting technologies are available, rotary die-cutting, flatbed die-cutting, steel die-cutting, and laser cutting. With over 20 years of industry experience in precision-cut components manufacturing, MSTR Printing can produce more than 100,000,000 precision-cutting units.

We can custom solutions to meet specific requirements, we are serving over 300 clients across various industries every year.

Screen Printing Service

MSTR Printing provides high-quality screen printing service for large quantities of film printing, it is compatible with a wide range of materials including textiles, ceramics, wood, paper, glass, and plastics. Screen printing can provide vibrant colors, it suits intricate graphics and text. we often use it for outdoor and heavy-use items.

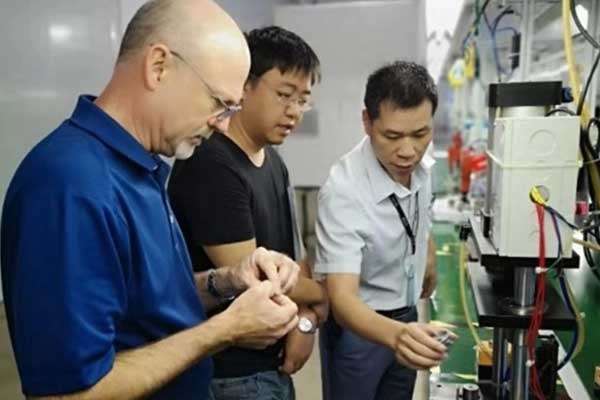

We use a semi-automatic screen printing machine, operators manually load and unload the materials, ensuring precise placement and alignment to ensure better efficiency and consistency.

With a 5,000 square meters factory, MSTR Printing can produce over 2,000,000 pcs of screen printing parts every month. Dedicated after-sales support and maintenance services are support.

Offset & Digital Printing Service

In MSTR Printing, digital printing is used for short runs and on-demand printing, we provide cost-effective customization for labels, flyers, posters, wallpapers, and more. Our digital printing supports a wide range of materials including paper, canvas, fabric, synthetics, and cardstock.

At the same time, we provide offset printing services for large-volume printing. We provide high-quality offset printing to produce crisp, clean, and professional-looking prints, it often used in high-quality brochures, graphic overlays, and newspapers.

MSTR Printing can produce over 2,000,000 pcs parts every month, we can custom digital printing and off-printing services for specific client requirements.

Steps To Custom Offset & Digital Printing

Design Creation

The process begins with crafting digital or physical designs, incorporating brand elements, information, and visuals tailored for Labels Decals.

Material Selection

Choose appropriate materials such as vinyl, paper, or specialty substrates, considering durability, adhesion, and environmental factors.

Printing

Employ advanced printing technologies like digital or screen printing to transfer intricate designs onto chosen materials, ensuring high-quality and accurate reproduction.

Adhesive Application

Apply adhesive to the labels, ensuring proper bonding with various surfaces while maintaining ease of application for Labels Decals on different products or surfaces.

Die cutting

Precision die-cutting shapes the Labels Decals, ensuring clean and exact cuts according to design specifications, creating a final product with polished edges.

Testing& QC

Inspection processes assess color accuracy, print quality, and adherence to specifications, ensuring each Labels Decals batch meets the highest standards before distribution.

- Control Panels for Electronic Equipment

- Medical Devices

- Military and Aerospace Electronic Equipment

- Automotive Dashboards

- Industrial Control Devices

- Consumer Electronics