When seeking nameplates with adherence to the standards of industry, you may have stumbled on engraving. Sitting here deciding whether engraved nameplates can address your business requirement and whether you are capable enough to carry it out is no secret.

Etched, screen-printed, engraved, and embossed nameplates all have their own advantageous properties. Though all hold several of the same traits, engraving stands out because it withstands wear and aging, along with the test of time. In this article, we will discuss the art of nameplate engraving, their advantages, and how you can easily incorporate it into your environment.

1. What Are Engraved Nameplates?

An engraved nameplate is created by etching, cutting, or inscribing letters and graphics into a material such as metal or plastic with mechanical devices or laser light. After engraving, the lower areas of the engravings may be left unfilled to create an informal look or filled with colored paint to produce a greater visual contrast. Each engraved character has measurable depth and profile so that fine legibility is offered regardless of years of sun exposure, abrasion, or chemical attack.

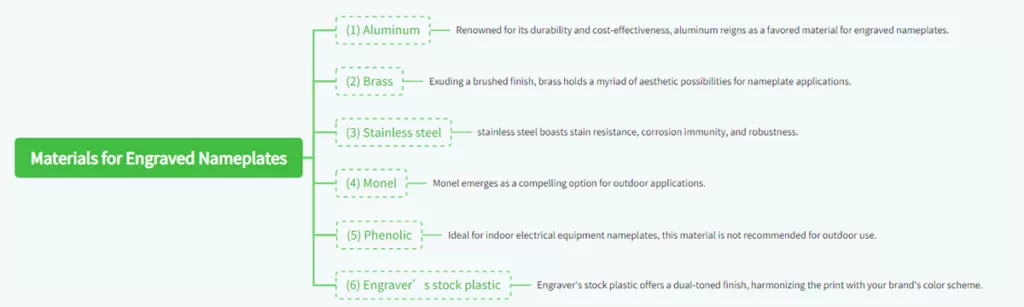

2. Materials for Engraved Nameplates

The making of engraved nameplates is a painstaking art that values detail. It begins by selecting the best material in accordance with your specific needs. Although some textures may be aesthetically pleasing, others offer greater resistance to withstand against the passage of time.

Engraved nameplates find their essence in materials of both plastic and metal origins. Among the esteemed selections are:

1) Aluminum

Famous for its durability and affordability, aluminum is the most widely used material in engraved nameplates. It is used more than other pure metals and alloys and hence is less expensive. The malleability of aluminum makes it the best choice for intricate designs, be it logos, diagrams, or custom fonts with intricate details. One of the lightest pure metals, aluminum possesses easy molding and bonding. The original color which is dependent on the source and finishing of the metal makes it an art.

2) Brass

Exuding a brushed finish, brass holds a myriad of aesthetic possibilities for nameplate applications. Plaques, mounted nameplates, engraved awards, and emblems radiate against the backdrop of its golden or scarlet tones. In industrial realms, this amalgam of zinc and copper exhibits durability and malleability under heat.

3) Stainless steel

An all-purpose solution to a range of nameplate applications, stainless steel is resistant to staining, corrosion, and wear. Durable and resistant to most wear and tear, stainless steel is shipped with a mill finish and a natural luster, blending beauty and strength.

4) Monel

Manufactured out of a combination of nickel and copper, Monel becomes a tough competitor for application outdoors. Sealed with tiny amounts of iron, carbon, and silicon, Monel is resilient to elements, from wind to rain. Its innate dark bronze or the polished gleam of nickel silver imparts an air of elegance to branding endeavors.

5) Phenolic

If you require a non-conductive product, attempt phenolic. Phenolic is a hard material made from a thermoset resin with low-glare and scratch-resistance features. Great for indoor electrical equipment nameplates, phenolic should not be used outside.

6) Engraver’s stock plastic

Engraver’s stock plastic offers a dual-toned finish, harmonizing the print with your brand’s color scheme. A cost-effective solution, plastic proves ideal for a plethora of indoor applications.

| Material | Weather Resistance | Appearance & Finish | Relative Cost | Machinability | Typical Application Environment | Remarks |

| Aluminum | High | Smooth, can be brushed or anodized in various colors | Low to Medium | Easy | Indoor and outdoor use, general industrial labeling | Lightweight, corrosion resistant, excellent for cost-effective engraving |

| Brass | Moderate | Bright gold tone, highly polished surface | Medium | Easy | Indoor environments, offices, awards, luxury products | Elegant appearance but prone to tarnishing if uncoated |

| Stainless Steel | Excellent | Silver-gray with mirror or brushed finish | High | Hard | Harsh industrial settings, marine or outdoor use | Exceptional durability and chemical resistance, suitable for long-term labeling |

| Monel (Nickel-Copper Alloy) | Excellent | Dull silver-gray, uniform matte tone | Very High | Hard | Marine, aerospace, and chemical environments | Superior corrosion resistance, used for critical or high-value equipment |

| Phenolic (Traffolyte) | Medium | Two-layer color contrast surface | Low | Easy | Indoor control panels, electrical and safety labeling | Flame-retardant, insulating, not suitable for prolonged outdoor use |

| Engraver’s Stock Plastic (Acrylic or ABS) | Low to Medium | Glossy or matte, available in many color combinations | Very Low | Very Easy | Indoor signs, office nameplates, prototype markings | Affordable and versatile, limited UV resistance outdoors |

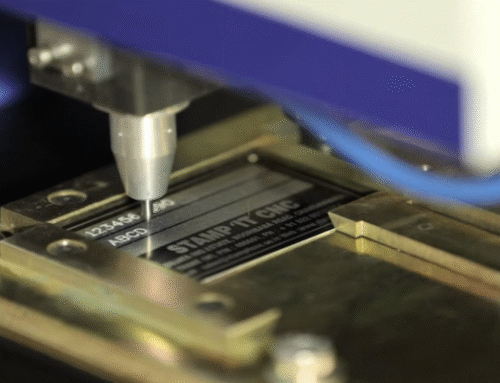

3. How Engraving Works?

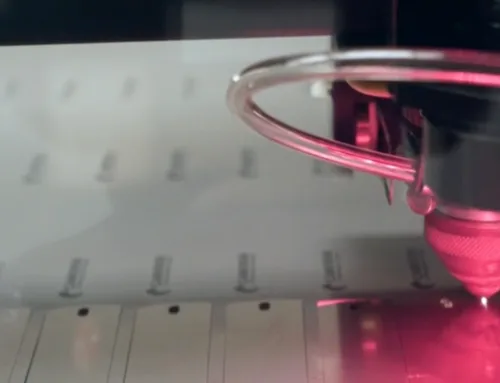

Engraving entails the creation of a recess within the chosen material, achieved through the precision of a rotary cutting tool synchronized with a computer. This time-consuming process results in a clean edge and cuts to a specified depth.

Alternatively, an engraver can use a carbon dioxide laser, which cuts a less deep incision. Laser engravings are also flexible enough to include barcodes along with custom text and graphics. With the hot intensity of the laser beam, metal or plastic substrate is vaporized and incised, exposing a cavity in precision.

The etched recess can be left bare or painted and highlighted, constructed in accordance with your personal sense of aesthetics.

Should you have specific specifications, our team will be there to assist by verifying blueprints and specifications to ensure the engraved nameplate turns out as desired. Or, the provision of an artwork file allows for selecting shapes, dimensions, and materials through our quote form, which can accept file types such as AI, EPS, PDF, CDR, DWG, and DXF.

Upon submission, proof will be provided for your scrutiny to guarantee adherence to all stipulations. Following your approval, the nameplates transition into production, with timelines contingent on order intricacies. MSTR prides itself on swift turnaround times, boasting an industry standard of two to three weeks for delivery.

4. Design Essentials for Engraved Nameplates

Design is equally as crucial as material and engraving quality. An effectively designed nameplate not only appears professional in appearance but will also provide for clear readability, simple installation, and long-term integrity. Following are five sensible design principles that work both for metal and plastic engraved nameplates.

1) Font, Text Size, and Line Width Standards

Typography will specify how to communicate information. In engraved plates, readability should never be compromised.

Font Choice: Sans-serif fonts such as Arial, Helvetica, or Univers are good choices because they have clear lines even when engraved. Avoid extremely decorative or narrow font styles that might lose their legibility when carved out of hard material.

Minimum Size: For most metals, letters need to be a minimum of 1.5 mm high to be legible after finishing or coating. Narrower letters may become merged and will be hard to read, especially under paint-filled engraving.

Line Width: Minimum stroke width needs to be 0.3 mm in CNC engraving and 0.2 mm in laser engraving. Thick lines are better to read and more resistant.

Depth: The typical depth of engraving is 0.05 mm to 0.3 mm and depends on the material and weight of the font. Deeper cuts make the part stronger but longer to machine.

Suggestion: Keep letters evenly spaced and use alignment guides to produce a neat, well-organized arrangement.

2) Border, Corner, and Edge Design

Edges and corners are features that contribute both to visual attractiveness and functionality.

Borders: A thin border (0.5–1.0 mm) is used to visually bound the content and to improve mechanical stability without adding stress at the edge.

Rounded Corners: Round corners for safety and aesthetic purposes with a radius of 1–2 mm. Sharp corners can catch on things or cut hands when installed. Adding a small chamfer or bevel gives the plate a more classy look and prevents peeling of surface coatings or anodizing. For indoor aluminum or brass nameplates, esthetic edge bevels can also provide additional aesthetic value.

Chamfered or Beveled Edges: Adding a small chamfer or bevel makes the plate look more refined and prevents peeling of surface coatings or anodized layers. For aluminum or brass plates used indoors, decorative edge bevels can also enhance visual appeal.

3) Layout for Logos, Symbols, Barcodes, and QR Codes

Today’s nameplates are no longer plain text identification. They can now be utilized to contain multiple features such as logos, warning symbols, serial numbers, or electronic codes for identification.

Logo Placement: Isolate company logo from text areas to avoid clutter. Place it consistently (most frequently top left or center).

Barcode and QR Code Size: Engrave code or laser-mark it at least 10 × 10 mm with high contrast between mark and background. Laser engraving will give the best effect for detailed fine QR code.

Spacing and Balance: Always test barcode readability after engraving and finishing to confirm it meets scanning requirements. Always test barcode readability after engraving and finishing to confirm it meets scanning requirements.

4) Mounting Holes and Installation Design

Mounting type of the nameplate dictates its aesthetic appearance and durability.

- Hole Placement: Typical hole sizes are 3–5 mm for rivets or screws. Maintain a minimum of 5 mm between the plate edge and the mounting point to prevent deformation or cracking.

- Mounting Options: Mechanical Fixing: Bolts, rivets, or screws for permanent installations.

- Adhesive Backing: Double-sided tape or 3M adhesive on flat surfaces and easy to assemble.

Magnetic or Hook-and-Loop Options: For temporary labels or detachable plates.

Thickness Consideration: Plates that are thinner than 0.5 mm will tend to warp under mechanical pressure and are thus best glued in place. Install pre-test procedures on test materials where possible to avoid warping or surface damage.

5) Readability, Visibility, and Contrast Optimization

The optimum engraved nameplate must be easily readable in various lighting and observing conditions.

- Contrast: High background-to-text contrast increases readability. Black-filled engraving on silver aluminum or white-filled engraving on dark anodized metal are examples.

- Surface Finish: Matte or brushed finishes reduce glare and allow ease in reading with high light. Polished finishes are more eye-appealing but introduce reflections.

- Viewing Angle: Make sure the text size and contrast are appropriate to the anticipated view distance. For equipment labels or control panels, plan for a minimum of 1 meter visibility.

- Environmental Conditions: Think about how sunlight, dust, or chemicals will impact appearance with time. Select coatings or colors that are resistant to fading and discoloring.

Prior to final production, print a one-to-one scale design mock-up to ensure layout balance and readability from actual-world distances.

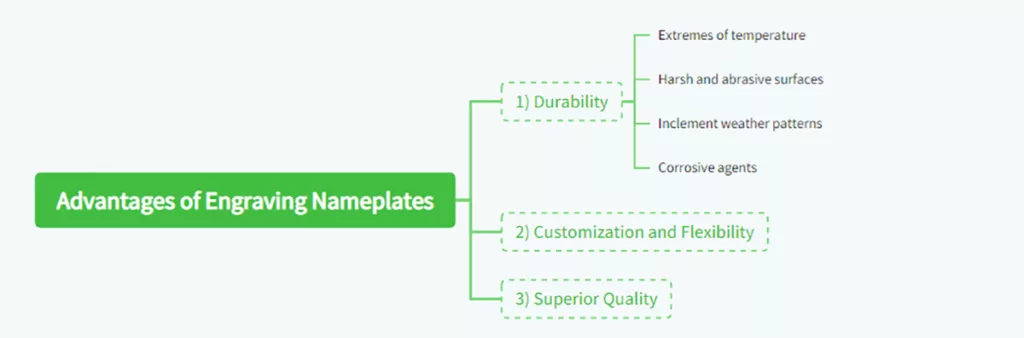

5. Advantages of Engraving Nameplates

The art of engraving positions nameplates in the possession of numerous benefits based on their durability and unparalleled craftsmanship. Engraving enables one to ensure perfection at the top level, as critical information is preserved by the durability of the products themselves. Engraving’s accuracy is carried to the intricate engraving of barcodes, special fonts, and specialty logos.

These advantages cumulatively put engraved nameplates ahead of other nameplates that have been produced using other methods. Among the greatest advantages of engraved nameplates is:

1) Durability

Remnants of ancient Roman etchings continue to resonate today, proof that this kind of artwork has persisted for so long. Infesting the walls of ancient buildings and holy churches, etched plaques decades old remain legible with ease. The clean and lush lines of engravings surpass those of etchings or stamps, adding to their resilience in withstanding wear.

Empowered by intricate algorithms and exacting cutting implements, engraving surpasses the precision of etching or silk screening. Set against the appropriate substrate, the sharp delineation endures diverse environments, including:

- Extremes of temperature

- Harsh and abrasive surfaces

- Inclement weather patterns

- Corrosive agents

2) Customization and Flexibility

Engraved nameplates epitomize a realm of boundless customization. While standard stamping will restrict you to the font library of the manufacturer, engraving, screen printing, and etching permit you to break away from such limitations. These techniques facilitate the production of a myriad of fonts, graphics, and designs engraved on metal or plastic substrates.

Whether it involves encoding key safety instructions with emotive pictographs or mashing serial numbers and contact information up with an attractively presented logo, the realm of possibility within engraved nameplates has no boundaries.

Laser engraving, specifically, opens up a world of unmatched versatility. Control over the thickness of varying materials and the depth of lines is at your command. Additionally, laser engraving takes its skills to rough, contoured, or uneven surfaces with effortless ease.

3) Superior Quality

The indefatigable strength, readability, and sleek appearance of nameplates engraved add up to a veritable showcase of adaptability. The irresistible charm, tangible to eyes as well as senses, which envelops an engraved nameplate puts it in a class of its own. Handicraft inherent in an engraved nameplate leaves no room for doubt, since it is the concrete testimony to the unparalleled standard that it epitomizes. Having its root back in centuries, engraved accessories are invested with a halo of antique beauty, sophistication, as well as eternal appeal.

With rotary and laser engraving machines both known for their precision, the accuracy and quality of engravings remain firmly consistent, whether orders are in the thousands or above.

6. Common Uses and Applications for Engraved Nameplates

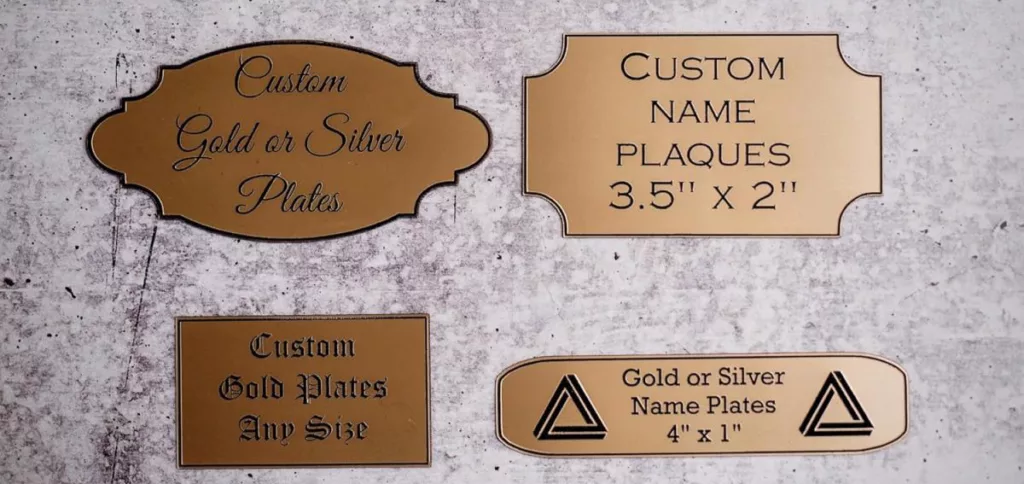

Various industries turn to engraved nameplates when in search of tailored solutions for their goods or machinery. The attractiveness of logos, branded logos, instructional schematics, and the like is magnified when inscribed on the lasting elegance of an engraved nameplate.

Although the association with engraved nameplates typically conjures up images of fancy plaques, award plaques, and mounted awards, their application seamlessly transfers to the industrial world. Engraved labels have a place on motors, pumps, asset identification tags, and the high-quality machinery that powers industrial processes.

Durable quality is a hallmark of etched nameplates, which makes them a requirement in permanent identification and safety instructions. In the industrial environment, these nameplates fulfill their function in labeling fixtures such as eyewash stations, displaying safety procedures on equipment, and as trusty indicators of fire exit doors, warning markers, and traffic direction markers in the expansive space of warehouse floors.

For manufacturers, rental firms, and companies tasked with managing a range of equipment, the utilization of laser-engraved asset identification tags is a prudent choice. Long-lasting engraved barcodes do not peel or fade, allowing easy asset tracking throughout the period.

Durability is a characteristic of engraved nameplates, so they are required for permanent identification and safety instructions. In the industrial setting, the nameplates have a role in labeling fixtures such as eyewash stations, communicating safety procedures on equipment, and being constant markers for fire exits, warning signs, and traffic route indicators on the vast canvas of warehouse floors.

For manufacturers, rental houses, and companies in charge of managing a variety of equipment, utilizing laser-engraved asset identification tags is an intelligent choice. Long-lasting engraved barcodes don’t peel and fade, and it’s simple to track assets over time.

Heat- and adversity-resistant engraved metal nameplates offer a method for concise directions even in the harshest conditions.In locales demanding swift operational guidance, such as boiler rooms, engraved nameplates stand ready to furnish concise directives for valve plates and pump tags.

An array of industries stands poised to reap the benefits of engraved nameplates, including:

1) Automotive Industry

In the automobile world, affirmation to stringent checks and federal requirements necessitates blatant exhibition of valid identification in every facet of an automobile. In the never-ending struggle to outshine competitors, the necessity of ageless branding that can withstand the test of time looms over the automobile industry. Engraving is an unrivaled opportunity for automakers to communicate essential information to dealerships, mechanics, and customers. Serialized components serve as guardians, ensuring the smooth compatibility of replacement parts with a particular make and model of a vehicle.

Nameplates stand as custodians of records for enterprises and contractors, facilitating seamless part tracking and information retrieval during resale transactions and unforeseen contingencies.

2) Aerospace Industry

Aerospace, where rigorous equipment and component standards reign supreme, shines the light on safety’s paramount concern. In this high-stakes sector, the judicious marriage of engravings and robust metal is a strategic choice. Metal engraved nameplates are, in effect, conduits, funneling vital information to both inspectors and personnel, such as technical specifications, serial numbers, locations of manufacture, and cautionary warnings. This strict labeling timetable not only increases aircraft compliance at inspection but also steers pilots clear of potential catastrophes.

Labeling initiatives provide staff with the power to navigate part inventories smoothly, make supply chain logistics simpler, and offer invaluable support in resale scenarios, organizational changeovers, and crisis management.

3) Construction Industry

For manufacturers of construction implements and tools, whose products witness daily action at bustling job sites, the incorporation of branded nameplates assumes paramount significance. These bespoke nameplates serve as heralds, linking the hallmark of quality products to the esteemed brand behind them. Armed with customized nameplates bearing the company logo, construction personnel, and site overseers can readily discern the provenance of the tools they wield.

Engraved nameplates within the construction sphere emerge as conduits for enhancing internal communication channels. The availability of written safety procedures, instructions, and OSHA regulations on the heavy equipment not only ensures the safety of workers but also encourages a culture of trust within the workforce. Even as the need for rigorous training for the operation of machines remains unyielding, engraved nameplates are reliable sentinels that ensure critical information such as weight capacity and tire pressure needs is always readily available.

No matter whether one wears the hat of a manufacturer or a builder caretaker, engraved nameplates are loyal companions in the quest to label equipment conclusively and battle the ravages of time. Their legible signage stays that way even under the harsh glare of daylight, sturdily withstanding the vagaries of weather and time.

4) Furniture Industry

To furniture making, an engraved nameplate brings a depth of high-end branding to the product that will endure along with the piece. Not only is this enduring mark proof of the maker’s expertise, but also it glows like a torch for customers wanting to trace the source of the cherished furniture four decades down the line. Apart from brand recognition, the nameplate provides room for essential contact details, guarantee, and record of manufacture.

The user’s meticulous identification of pieces of furniture has serious implications for inventory control, serving both furniture artists and rental companies by turn. The inscribed identifiers provide for the meticulous listing of products during high-volume production runs and serve as incontrovertible proof of ownership within rental inventories, guarding against loss.

5) Original Equipment Manufacturing Industry

Within the original equipment manufacturing industry, engraved nameplates are precious allies to safeguard end-users who are venturing into unfamiliar equipment and tools. For those items that are going to weather the brutality of extreme environments and repeated use, the enduring beauty of an engraved nameplate is its ongoing preservation of critical safety information and operation procedures.

Etched nameplates are avenues for communication of manufacturing pedigree, technical specifications, serial identifiers, and warning advisories. Long-term readability of etched recess ensures readability of critical information under all conditions over an extended period of time. Original equipment manufacturers must ensure strict adherence to regulatory provisions relating to mark and label permanency, demonstrating the importance of obtaining etched items from Underwriters Laboratories (UL) approved vendors. Prior to product dissemination, it is imperative to engage with us to ensure meticulous adherence to industry regulations governing labeling standards.

6) Custom Designers

For artists of original pieces of art, the charm of engraved nameplates lies in their unshakeable capacity to be customized. Creating either single commission pieces or limited editions, an engraved nameplate is a marker of quality, injecting a touch of sophistication into the finished piece. Engraving lends itself to the accuracy of creating nameplates that are as unique and exceptional as the art that is envisioned, complete with streamlined contact information directing clients to the artists behind the artistry.

Etched nameplates not only offer an increased visual interest but also offer a more durable option to the standard labeling practice. In close collaboration with designers, we navigate industry regulations to deliver inspection-compliant, long-lasting etched nameplates that will endure for years to come.

If uncertainty shades your vision, rest assured we are here waiting to recommend materials that can withstand the scale of your work and propose budget-friendly alternatives. With your blueprints and specifications in hand, our artisans execute impeccable engravings in any quantity, promising a perfect marriage of form and function. Embark with us today by making a free quote request or submitting your artwork and details for a custom beginning.

7. Engraved Nameplates Cost Structure Analysis

Behind every engraved nameplate, there is more than just engraving time and material usage. Its final price reflects how efficiently materials are chosen, how precisely machines are programmed, and how wisely each process is planned. This breakdown of costs allows purchasing managers and designers to make better decisions that balance performance, quality, and economy.

The total cost of manufacturing an engraved nameplate is mostly comprised of material cost and process cost, with some secondary elements such as finishing, packaging, and quality inspection.

Material Cost

This refers to the raw sheet or substrate from which the nameplate is cut. The price depends heavily on the material type, sheet thickness, and surface treatment applied before or after engraving.

- Material Type: Metals such as stainless steel or Monel are higher in price due to their density, corrosion resistance, and more difficult machining properties. Plastic-based engraver’s stock is inexpensive but not suited for harsh outdoor environments.

- Thickness: A thicker sheet increases stability and durability but also directly raises both material and engraving time costs. The majority of industrial nameplates consider 0.8–1.2 mm thickness as a balance between strength and price.

- Surface Treatment: Finishes such as color coating, polishing, anodizing, or protective lacquers are additional cost because they require additional handling and equipment.

Anodized aluminum, for example, costs 20–30 percent more than bare aluminum but has significantly better appearance and corrosion resistance.

Processing Cost

This component covers all the labor and machine time involved in turning the raw sheet into a finished product.

- Engraving Method: CNC rotary engraving requires tool paths to be generated and cutters to be changed according to font depth or logo complexity. Laser engraving, although faster on thin materials, requires more equipment investment and more speed and power control accuracy.

- Setup and Programming: Each design requires its own layout file, engraving parameters, and sometimes fixturing. Even for a small plate, the setup time will be 15–30 minutes, which is costly if a single item is produced.

- Secondary Processes: Edge cutting, deburring, color filling, drilling mount holes, and final polishing have incremental costs. These processes are typically underestimated when quoting but have a great impact on total labor time.

In short, material dictates the underlying cost, and engraving complexity and post-processing dictate how that cost is multiplied.

8. Material and Process Selection for Instrument and Equipment Panels

For an equipment or instrument control panel, an engraved nameplate is not merely a cover plate for decoration. It usually includes important information such as operating instructions, safety warnings, and calibration details. As the panels are subjected to extensive handling, heat, and possibly chemical cleaning, material and process selection must be based on functionality and durability.

Step 1: Evaluate the Application Environment

Engineers should think about where and how the equipment will be used prior to selecting the material.

- Indoor lab equipment: Requires clean appearance, minimal chemical resistance, and high readability under artificial lighting.

- Outdoor or field instruments: Need high UV resistance, corrosion resistance, and high durability in the presence of moisture and temperature fluctuation.

- Industrial production lines: Often involve oil, vibration, and solvents and call for physical ruggedness along with chemical stability.

A proper assessment of these conditions helps narrow down suitable materials before considering cost.

Step 2: Choose the Right Material

1. Aluminum (Anodized or Brushed)

Best for general-purpose instruments where lightweight, corrosion resistance, and clean visual design are desired. Anodized aluminum provides a hard surface with color stability and excellent laser engraving performance. Common in laboratory analyzers, power control units, and medical device housings.

2. Stainless Steel (304 or 316 Grade)

Ideal for harsh or hygienic environments, such as chemical plants, marine instruments, and food-processing equipment. Highly resistant to corrosion, abrasion, and frequent cleaning. Suitable for deep CNC engraving or fiber laser etching with dark contrast.

3. Phenolic Laminate (Traffolyte)

Practical for control panels that require electrical insulation and color-coded layers. Lightweight and easy to engrave, commonly used for switch labels and circuit identifiers. Not recommended for high UV or outdoor exposure due to possible color fading.

4. Brass or Monel (Specialized Use)

Brass offers a premium look for laboratory or vintage-style instruments but needs a protective lacquer coating. Monel, though expensive, performs exceptionally well in high-humidity or corrosive gas environments.

Tip: For electronic instruments, avoid using conductive metals directly on exposed electrical surfaces unless properly insulated.

Step 3: Select an Appropriate Engraving Technique

1. CNC Rotary Engraving

Produces deep and tactile markings with a professional finish. Suitable for aluminum, brass, and phenolic laminates. Recommended for panels requiring embossed-like readability or paint filling.

2. Laser Engraving

Offers precise detail and flexibility for fine fonts, small serial numbers, or barcodes. Works best on anodized aluminum and stainless steel surfaces. Fast and clean process with no physical tool wear.

3. Combined Techniques

For premium instruments, a combination of laser marking for text and CNC engraving for scales or logos creates both depth and legibility. This two-step process yields a premium appearance and long-term legibility.

Step 4: Surface Finishing and Color Contrast

An engraved panel must be legible under different lighting and use conditions. To accomplish that, attention must be given to both contrast and surface finish.

- Anodized Aluminum: Dark laser marking on silver or black anodized base gives the most legible.

- Paint-Filled Engraving: Black or white epoxy paint in CNC-engraved grooves improves contrast and resists wear.

- Brushed Finish: Reduces overhead light glare, ideal for control-room and laboratory equipment.

Check readability at normal viewing distances of 0.5 to 1.5 meters before final approval.

Step 5: Durability and Maintenance Considerations

Durability is often the deciding factor for industrial panels. To achieve maximum long service life, manufacturers should: Perform abrasion and solvent resistance tests on finished samples. Use UV-stable coatings on outdoor panels to prevent fading. Design out deep recesses or sharp edges where cleaning residues or dust can trap.

Get even adhesion of adhesives or mechanical fasteners to prevent panel lifting over time. Properly maintained engraved nameplates will survive 10 years or more even in severe operating environments.

Step 6: Balancing Cost and Performance

Cost optimization should never compromise readability or reliability. While stainless steel panels are the most durable, anodized aluminum often offers the best ratio of appearance, weight, and price. For high-volume instruments, laser engraving on pre-anodized sheets ensures consistent quality and repeatability with minimal setup cost.

The smartest strategy is to align material and process with the product’s lifecycle. If the equipment is designed to last decades, invest in materials that can match that lifespan.

9. Conclusion

In summary, the craft of engraving nameplates is anything but labeling; it’s the combination of skill, brand character, and usability across different sectors. Though ageless elegance for the furniture business and safety might be worlds apart for the aerospace business, the engraved nameplates are enduring records of accuracy and artistry.

Original equipment manufacturers rely on such markers to guide customers through intricate machinery, and custom designers employ them to infuse a touch of bespoke whimsy into their designs. As we journey through the intricate weft of industries, let us remain consistent to the timeless appeal of engraved nameplates as not merely indicators of origin but as signposts of enduring quality and distinction.

Leave A Comment