Die cut labels are the reigning choice for outdoor stickers, being renowned for their looks and flexibility. That said, the myriad of choices of custom stickers can typically create decision-making dilemmas. Fear not, as this is a definitive guide that will cut through the confusion and provide an overall picture of all things related to die cut labels.

1. What are Die Cut Labels?

Die cut labels are stickers cut precisely to a specific design or shape. The labels are applied for various purposes, such as logo stickers, brand stickers, or brewery stickers. “Die cut” derives from the process of cutting implemented to achieve the odd shapes, which is now the general term used to call stickers cut into special shapes.

Previously, a die made of steel was employed to precision cut stickers into intricate shapes, providing them with a custom appearance. Even though technology has improved, newer cutting methods using plotters and lasers replaced the original die, the sticker industry retained the name “die cut.”

The appeal of die cut stickers is that they can tease with their fanciful shapes and contours, which makes them ideal for brand product branding. Their pleasing visual appeal not only makes the sticker eye-catching but also the powerful way in which effective advertisement is made.

2. Die-Cut Sticker Benefits

Die-cut labels have a few advantages that distinguish them from regular stickers:

1) Brand Identity Recognition

Die-cut stickers are also a powerful advertising tool for corporations. By defining your logo or brand image into a unique die-cut shape, the stickers draw attention immediately and leave a lasting impression on your audience.

2) Customization and Creativity

One of the standout features of die-cut labels is the freedom to customize their shapes entirely. Used to emphasize your logo, picture, or original design, die-cutting gives you the precision to turn your creative ideas into reality.

3) Durability

Being made of good quality, long-lasting materials, die-cut labels are very resilient to withstand different environmental conditions. Having a long lifespan, they can be applied for indoor as well as outdoor environments, which makes them receive extended exposure for your message.

4) Professional Appearance

The die-cutting process gives these labels a professional and elegant touch, making them more attractive. Die-cut stickers present a completed appearance with their sharp edges and personalized shapes that distinguish them from standard stickers, causing them to stand out more.

3. What are the Other Custom Label Styles?

Enter the world of custom labels, where a host of styles, sizes, cutting options, and specialty materials are waiting to elevate your branding. Let’s examine some of the most common permutations in the world of custom labels.

1) Kiss Cut Labels

Enter kiss cut labels domain, where accuracy cutting intersects with customization. In contrast to traditional die cut stickers, kiss cut labels peel off in sophistication from the backing paper, leaving behind beautiful designs in immaculate fashion. This new cutting method, besides deterring deformation of design, offers an artistic platform for the incorporation of other branding elements like QR codes, websites, and social media details.

2) Label Sheets

Enjoy the versatility of label sheets, a variation of kiss-cut stickers. Label sheets contain various peel-outs, typically 3 to 5, that allow a variety of various sticker design options from a single sheet. Ideal for accentuating various branding options, label sheets offer a design area to unveil your brand personality with a mix of message and design.

3) Hang Tag Labels

Step into the realm of hang tag labels, a fusion of die cut and kiss cut styles tailored for retail clothing, hats, and similar products. These versatile labels serve a dual purpose, exquisitely combining a price sticker with a sticker element. Conveniently applied through retail clothing guns, hang tag labels ensure that every customer leaves with a branded sticker in hand, thereby qualifying as an absolute retail branding necessity.

4. What is the Best Material for Die Cut Labels?

In the case of the best material for die cut labels, both durability and cost should be at the top of the list. Die cuts made from standard die cuts are commonly made of outdoor-grade vinyl, which are more resistant to most elements like sunlight, rain, and car washes. Materials such as polyester, BOPP, static cling, and paper also serve good alternatives to produce die cut labels based on different purposes and needs.

Material choice for die cut labels is a significant decision that not only determines the visual appearance but also the long-term reliability. Each substrate acts differently based on temperature, humidity, and surface conditions. Being aware of the price-to-performance ratio allows balancing the needs of functionality with the cost involved.

1) Common Material Options

Vinyl (PVC): Durable and flexible, vinyl can be applied indoors and outdoors. Waterproof, sunproof, and resistant to mild chemicals, vinyl works best for equipment markers, auto decals, and industrial markers.

Polyester (PET): Excellent dimension stability and heat resistance. Widely used in electronics, automobile, and medical equipment where labels must not deteriorate with exposure to heat and cleaning agents.

Polypropylene (BOPP): Moisture-resistant and cheap, BOPP is commonly used for food packaging, cosmetics, and containers. It provides clear and shiny finishes, even though it is not as heat-stable as PET.

Paper: Economical and ideal for short-term or indoor labeling such as shipping labels or product identification. However, it is sensitive to moisture and abrasion.

Clear or Transparent Films: Provide a “no-label” look and excellent brand presentation. Manufactured generally from PET or BOPP, they require clean application surfaces for optimum adhesion.

2) Durability and Cost Comparison Across Environments

| Material | Relative Cost | Durability | Heat Resistance | Chemical Resistance | UV Stability | Recommended Use |

| Paper | Low | Short-term | Low | Low | Low | Indoor packaging, barcode labels |

| BOPP | Low to Medium | Moderate | Moderate | Moderate | Moderate | Food and cosmetic packaging |

| Vinyl (PVC) | Medium | Long-term | Good | Good | Good | Outdoor labels, equipment tags |

| PET (Polyester) | Medium to High | Long-term | Excellent | Excellent | Excellent | Automotive, electronics, machinery |

| Polyimide | High | Very long-term | Excellent | Excellent | Excellent | High-temperature industrial and PCB labeling |

The following table provides a general rule of thumb to cost and durability levels. Industrial buyers can match materials to work environments: i.e., PET and polyimide films are employed with high-temperature equipment, and vinyl remains the most useful one for exposure outdoors.

3) Common Failure Modes and Material Selection Guidelines

Poor choice of a label material that does not take into consideration actual operating conditions can lead to premature failure. The most common problems and how correct material selection can prevent them are the following:

Edge Lifting or Peeling: Frequently the result of incompatible adhesive and surface finish. On powdered or textured finishes, utilize high-tack adhesives or flexible vinyl substrates that can track uneven surfaces.

Color Fading or Yellowing: Ink and material degradation through prolonged exposure to UV. Treat with UV-resistant PET or outdoor vinyl with UV-stabilized coatings to maintain appearance.

Adhesive Breakdown: Chemical contact or excess heat can lead to weakening of the bond. Select high-performance adhesives rated for higher temperatures or chemical resistance.

Cracking or Brittleness: Thin paper or low-grade BOPP can crack in cold or dry environments. For low-temperature resistance, flexible vinyl or PET provides better dimensional stability.

Surface Bubbling or Air Entrapment: Happens when application conditions are not clean or smooth. The use of pressure-sensitive adhesive systems and lamination under proper pressure assists in achieving better adhesion. Proper material selection relies on a compromise of toughness, cost, and resistance to the environment. Take label’s exposure conditions, lifetime, and adhesion surface into account before ordering. Negotiate these variables with your supplier so that the material selected suits both your technical requirements and commercial objectives.

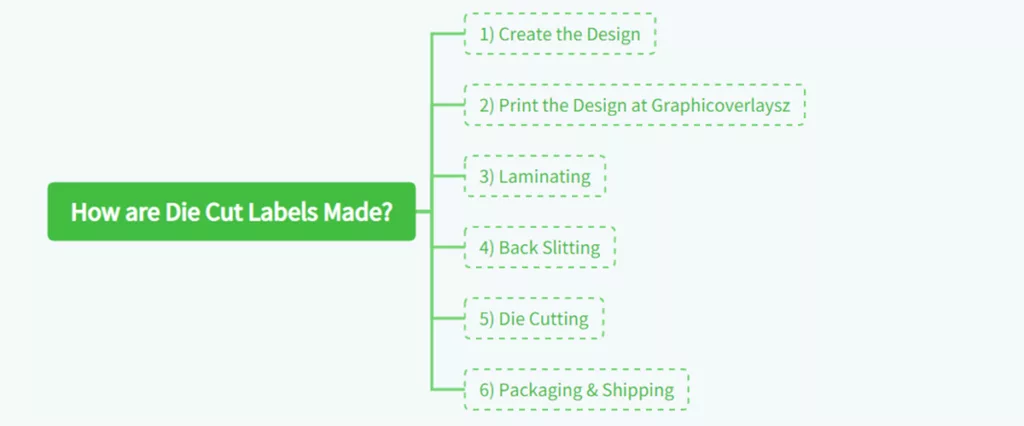

5. How are Die Cut Labels Made?

Die cut label manufacturing is an art of meticulous steps that ensure the quality and shelf life of the final product. Let us delve into each step in depth below.

1) Create the Design

To create any shape a die cut label, you begin by designing the shape in design software like Adobe Illustrator. In case you require assistance, our skilled art department is here to help with bringing your vision to life.

2) Print the Design at Graphicoverlaysz

Select your desired size and quantity of the die cut label on our product page. We will supply a free PDF proof at the time of checkout for you to sign off prior to printing. Depending on size of order and complexity of artwork, we utilize various printing techniques like screen print for outdoor longevity or digital print for smaller orders.

3) Laminating

Once printed, the labels are subsequently laminated with a matte or gloss laminate for added protection and durability. The coating guards the quality of print against wear and tear over the long term.

4) Back Slitting

Back slitting is a process of slitting through the liner paper of die-cut stickers to enable easy usage by facilitating easier peeling. The process enables very easy application and a smooth user experience while applying the stickers. A good back slit cannot be overstated for optimum sticker usability.

5) Die Cutting

Leaving the cutting process, die cut labels are shaped by plotters, laser cutters, or steel rule die cutters, with clean-cut and precise edges for that professional look.

6) Packaging & Shipping

Following cutting, the stickers are then packaged for good, whereby they are packaged in batches of 100 and shrink-wrapped for security in transit. Thereafter, the packaged stickers are then boxed and shipped for delivery onto your front doorstep.

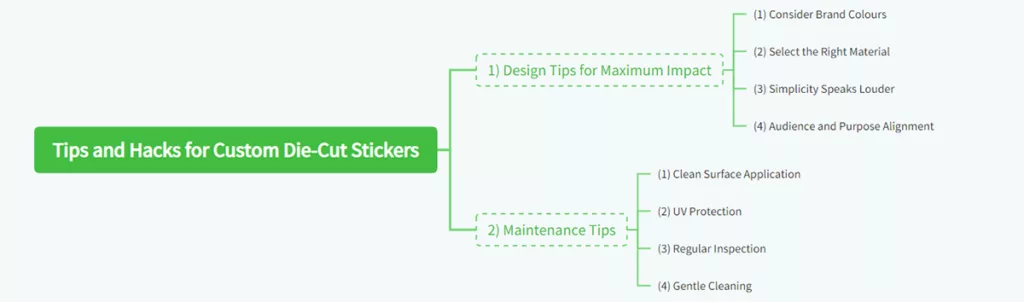

6. Tips and Hacks for Custom Die-Cut Stickers

Exploring the realm of custom die-cut stickers unveils a world of tips and tricks for both design enhancement and maintenance to maximize their impact.

1) Design Tips for Maximum Impact

The art of creating effective die-cut stickers is in mindful design choices that capture and attract your target audience. A few of the design recommendations to make your stickers all the more effective are below:

(1) Consider Brand Colours

Coordinate your die-cut sticker colors with your brand identity to make a unified visual language in all marketing channels.

(2) Select the Right Material

Tailor your choice of sticker material to the environment intended for use, where it will be strong and long lasting, such as indoor, outdoor, or on a product.

(3) Simplicity Speaks Louder

Emphasize clean lines and vibrant colors in your die-cut designs to make a dramatic visual impact. Let the unique design elements command attention while making your message brief and potent.

(4) Audience and Purpose Alignment

Personalize your die-cut stickers to meet your specific audience and application, be it promoting a business or cause. Ensure that your design is able to effectively communicate your message to your desired audience.

2) Maintenance Tips

Maintaining the quality and effectiveness of your die-cut stickers demands strict maintenance practices. Observe these tips to keep your stickers effective in their appeal over time:

(1) Clean Surface Application

Before applying die-cut stickers, clean and dry the surface to maximize adhesive performance and life.

(2) UV Protection

For outdoor exposure stickers, add UV-resistance coatings during printing to resist fading and color brightness retention.

(3) Regular Inspection

Regularly check your die-cut labels for wear or peeling and adjust them promptly to extend the life of the stickers.

(4) Gentle Cleaning

When dusting surface areas with die-cut stickers, apply soft cloth and soap and never abrasive material or chemicals that could compromise the strength of the sticker.

7. Cost Structure and Pricing Factors

When buying custom die cut labels, understanding the cost breakdown helps you make more savvy purchasing decisions and maintain more control over your manufacturing budget. The price is established based on a mix of material selection, printing technology, finishing features, and logistics configurations.

1. Material and Adhesive Selection

Substrate selection between vinyl, PET, or BOPP will directly impact cost and performance. Films and hot-melt adhesives are inherently more costly than paper-based products, but they are more weatherable and stronger. Industrial adhesives and cover coatings are typically required when labels must withstand UV radiation, water, or chemical exposure. The total material cost rises with these selections, but it ensures stability and permanence in extreme environments.

2. Printing and Finishing Techniques

Printing processes differ in look and cost. Digital printing is most suitable for short run or variable prints, while screen or flexographic printing becomes economical in bulk. Finishing processes such as lamination, spot gloss, metallic ink, or protective coatings could increase the cost but improve scratch resistance, gloss, and color hold. Visual impact versus functionality balance prevents you from spending more than you need to.

3. Cutting Complexity and Tooling

Die cutting complexity affects both cost and quality. Basic rectangular or round cuts are inexpensive, but complex shapes or close tolerances need specialized tooling and reduced production speeds. If inner cuts or multi-level constructions are a part of your design, setup time and tooling costs can increase. For repeat orders, using existing dies and reusing them is a cost-effective method to minimize long-term expense.

4. Volume, Order Frequency, and Lead Time

Unit price decreases as order quantity increases, but not in a strictly linear way. Once setup costs and initial material waste are covered, larger production runs can significantly lower the per-label cost. Long-term purchase commitments and reorder transactions typically receive preferential pricing through firm scheduling and material planning. On the other hand, expeditious orders with high-priority production or express shipment typically come with additional fees.

5. Packaging, Logistics, and International Shipping

Packaging format and transportation method also affect total cost. Labels provided on rolls, sheets, or as individual cut pieces will require special handling and packaging processes. For export shipments, purchasers need to consider freight mode, customs clearance, and export packaging requirements such as moisture-proof overwrapping and reinforced cartons. Packing density maximization can effectively reduce freight expense and warehouse space.

6. Testing, Certification, and Quality Assurance

For industrial, medical, or electronic equipment, labels may need compliance with standards such as UL, RoHS, or REACH. Certification and testing is worth but costly. The use of certified materials reduces product failure risk, improves compliance, and reduces warranty claims. In the long term, this investment can be cheaper than using uncertified substitutes.

Having a clear understanding of these cost drivers means you can communicate more effectively with your label converter. When you request a quote, you need to be sure on material type, adhesive performance, durability level, finishing requirements, and expected order size. This clarity allows your supplier to provide an optimized pricing plan that aligns both technical performance and commercial goals.

8. Uses for Die Cut Labels

Die cut labels, those adorable stickers carefully cut to the shape of car windows, water bottles, and laptops, has turned into a popular favorite in American culture. The stickers not only express individuality but also express brand affiliations. Let us explore the wide range of applications of die cut stickers and see how they are cleverly used.

1. Branding Labels

For new brands wanting to make a big splash and push their new releases, branding labels are an extremely powerful weapon. Paired with a good solid social media push, these labels can launch brands into the stratosphere, blending seamlessly with existing branding guidelines.

2. Logo Labels

Each brand carries a signature logo, and logo stickers provide a simple yet effective way to propagate brand image. Sharing these stickers between employees and consumers can yield dramatic dividends, creating brand visibility and having a lasting impression.

3. Brewery Labels

Since the craft brewery boom of the past two decades, brewery labels have been highly prized items. The labels are a versatile medium for breweries to spread the word, promote new beer offerings, and build a following of enthusiasts.

4. Contingency Labels

Most typically seen on the sides of racing vehicles, contingency labels are 36 square-inch brand stickers applied strategically by automobile manufacturers for marketing purposes. They wind up on whatever surface is available, from refrigerators to windows of automobiles, to get maximum visibility of the brand.

5. Back Print Labels with QR codes

Back print labels, an easy sticker type, offer a unique chance to access the backing paper for secondary features of branding, such as QR codes. Aside from maximizing brand visibility, this multi-tasking approach provides added value to the consumer, which makes them extremely popular among die cut sticker buyers.

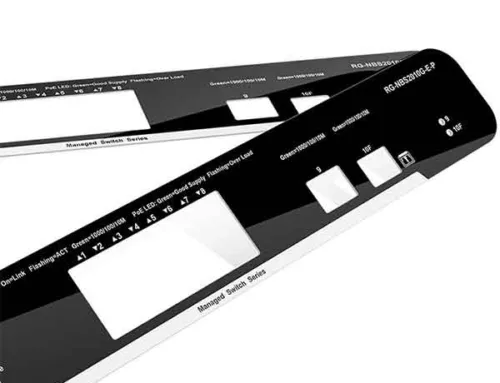

In addition to generic retail or advertising uses, die cut labels play a major role in industrial, commercial, and regulated sectors where appearance and performance are as important as they are in areas such as industrial equipment. The following are some examples of how different industries use die cut labeling.

1. Industrial and Machinery Labeling

In manufacturing environments, equipment must display clear operational instructions, voltage warnings, or maintenance information. Die cut vinyl and polyester labels are especially ideal for this use due to their resistance to oil, heat, and abrasion and high adhesion. For example, an injection molding equipment manufacturing plant uses PET warning labels that fail to become unreadable even after years of continuous operation in hot conditions.

2. Automotive and Transportation

Automotive components such as engines, batteries, and dashboards require hard-wearing ID labels that will withstand vibration, fuel, and high temperature cycles. Polyimide or PET die cut labels also frequently find use on compliance markings and serial number identification. One automotive company supplier improved traceability by switching to solvent-resistant PET labels that were not degraded by degreasing and painting processes.

3. Electronics and Electrical Devices

Printed circuit boards, power tools, and chargers often use precision die cut labels to label parts and verify compliance.UL-approved polyester films provide heat stability and insulation safety. For instance, one electronics company used laser-cut PET labels to label circuits that were automatically applied to SMT lines without leaving any adhesive residue.

4. Medical and Laboratory Equipment

Medical devices and laboratory equipment need clean, chemical-resistant labels that will meet regulations. Die cut labels printed with medical-grade inks maintain legibility after repeated sterilization. A diagnostic device supplier used custom die cut labels with matte overlamination to prevent glare during barcode scanning in hospital settings.

5. Logistics, Warehousing, and Asset Tracking

Die cut labels are widely used in inventory management, asset tagging, and cold-chain logistics. BOPP and synthetic paperstocks hold up in refrigerator or outdoor storage. For example, one logistics company employed robust barcode labels that remained legible after condensation exposure during transport from Asia to Europe.

6. Food, Beverage, and Cosmetics

Brand presentation and moisture resistance are key for consumer packaging. Clear BOPP or PP die cut labels create a premium “no-label” look for bottles and jars. A beverage producer used custom-cut transparent film labels to improve shelf impact while reducing label waste by optimizing sheet layout.

7. Energy and Outdoor Applications

Solar panels, outdoor equipment, and outdoor devices employ UV-resistant and weather-resistant labels. Outdoor-grade vinyl or laminated PET provides long-term adhesion in sunlight, dust, and humidity. A firm, for example, substituted screen-printed plates with laminated die cut labels in their product line of energy equipment, reducing cost and accelerating production without sacrificing durability.

These industrial uses demonstrate how die cut labels function not just as branding items but also as essential components of identification, compliance, and safety systems. When ordering labels for your products, always match material, adhesive, and finishing to the working environment and regulatory specifications. The correct combination delivers consistent performance, long-lasting adhesion, and professional appearance in any industry environment.

9. What are the Design Considerations that Matter for Die Cut Labels?

Design considerations are the building blocks of creating effective die-cut labels, determining the result of your design with precision and efficiency. From designing safety zones around your design to selecting white borders instead of full-bleed designs, every choice affects the appearance and functionality of your labels. Mastering the art of interior die cuts and how they can elevate your design is essential in producing distinctive and memorable labels. Let us dig deeper into these influential design factors to make your die-cut labels be different and leave an impression!

1) Safety Zone Around the Design

When cutting die-cut stickers, consider incorporating a safety zone around the design so there will be enough space for small cutting variations. The typical safety zone is 3/32″ (.09375″). Keep this in mind when putting vital pieces at the edges of the design.

2) White Border vs. Full Bleed

Both white border and full bleed patterns can contribute to the visual attraction of stickers. Consider the context while choosing between the two. Black designs without a white border may become invisible on black backgrounds, such as car windows. In those cases, it is advisable to use a white border because it will highlight the design.

3) Interior Die Cuts

Interior die cuts involve cutting out inside the design. These are particularly useful if the sticker is going to need to be applied on top of an existing component. While we can perform interior die cuts in a few instances, it is better to call our customer service department to determine whether your artwork can be utilized for this element.

10. How to Procure a Die-Cut Label and Select a Supplier?

Selecting the right die cut label supplier is equally important as finding the right materials or printing method. A good manufacturer not only provides consistent quality but also consistent lead times, reasonable costs, and prompt technical service throughout your project.

1. Evaluate Production Capabilities

Start with an understanding of the supplier’s manufacturing basics. Verify whether they have in-house printing, die cutting, and finishing equipment rather than outsourced large production phases. A vertically integrated facility can better manage quality, restrict delivery time, and ensure consistency in reorders. Ask for details on their production lines, including available printing technology, largest sheet size, and cut accuracy.

2. Review Material Sourcing and Quality Control

A good vendor uses traceable raw material of international quality. Verify that they can provide certifications such as ISO, UL, or RoHS if necessary. Inquire about their quality control procedure, including inspection of incoming materials, testing for color consistency, and adhesion testing. The presence of a written inspection procedure is typically a sign of a sophisticated manufacturing organization.

3. Assess Experience in Your Industry

Seasoned industry segment suppliers can anticipate technical challenges and suggest material or adhesive combinations that satisfy your requirements. A producer who has experience in medical device labeling, for example, is aware of sterilization resistance, while a producer of industrial labels can suggest chemical durability as well as surface compatibility. This industry-specific understanding leads to improved communication as well as reduced design cycles.

4. Compare Quotation Transparency and Service Terms

A good supplier provides you with accurate quotations clearly listing material grade, printing process, finish type, and unit price per different quantities. Transparent pricing allows you to take decision making based on facts and avoid extra expenses. Evaluate the supplier’s terms regarding lead time, minimum order value, payment term, and after-sales service. Proper documentation of above facts avoids misinterpretations in long-term association.

5. Request Samples and Pilot Runs

Before finalizing mass production, always request pre-production samples or pilot lots. Verify color accuracy, adhesion quality, die cut accuracy, and packaging quality. A good supplier should be willing to make changes according to your feedback and make suggestions for cost saving or material improvement.

6. Communication and Project Management

Communication is an important part of successful sourcing. Choose partners who have good response time, good technical explanation, and proactive production update. Effective project tracking and open lines of communication minimize delays and guarantee smooth order execution, especially for deadline-driven industrial or export orders.

Working with a seasoned die cut label manufacturer reduces risks along the supply chain. Don’t focus solely on cost; consider total value, production reliability, technical know-how, and service responsiveness. A top supplier is a long-term partner who enables your business growth through consistent quality, guaranteed lead times, and trusted counsel.

11. Conclusion

Die cut labels are an off-the-shelf product and the die-cut one is a wonderful choice. In brief, die-cut outdoor labels offer a fantastic chance to brand your business, show your personality, or simply add some personality to your stuff. Constructed of tough and weather-resistant materials, die-cut outdoor labels are designed to endure harsh outdoor weather, making your message come alive and with plenty of strength for years and years to come.

Whether you prefer your own personal design or prefer to begin with a pre-made template, there are ample options to be found to suit your style and budget. Welcome die-cut outdoor labels into your life today and download unlimited creative possibilities and leave an indelible mark!

Leave A Comment