Custom Domed Stickers from MSTR

Est. 2005, MSTR is a Chinese leading domed sticker manufacturer supplying high-quality brand solutions with the capacity to produce more than 1,000,000 pieces per month. Domed stickers from our range feature eye-catching 3D visuals and are protected with polyurethane resin for long-term durability, giving an impressive glossy long-term finish and increasing brand visibility.

Custom domed stickers tailored to your specifications are our specialty, offering a selection of shapes, sizes and styles for you to select from. Domed stickers can be seen everywhere from automotive emblems and electronic parts to brand promotion and more upscale brand promotion – providing professional yet distinctive appearance. Built for durability with UV light resistance and chemical exposure protection so they will retain color vibrancy and adhesion under adverse conditions.

Preferred by global brand leaders, MSTR domed labels provide an affordable visual opportunity to enhance brand visibility. With high-quality production guaranteed, contact MSTR when you’re ready to enhance your brand’s strength with excellence-grade domed labels.

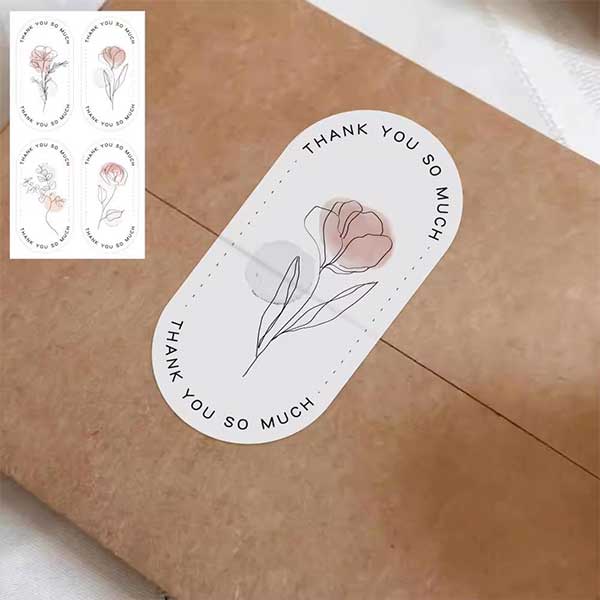

Featured Domed Stickers

Resin Domed Labels

MSTR’s specialty is high-performance resin domed labels with a hard, crystal-clear polyurethane finish that maximizes appearance and durability. Engineered for scratch resistance, water resistance, and UV protection, our labels maintain their shiny appearance and vibrant colors even in the most challenging conditions.

The 3D effect and premium texture provide a professional and eye-catching branding solution. With custom OEM & ODM capabilities, MSTR delivers precision-crafted domed labels tailored to diverse industry needs.

Epoxy Dome Stickers

MSTR’s epoxy dome Stickers have a resilient, high-clarity epoxy resin covering, available in both soft and hard finishes to match various uses. With superior yellowing resistance, flexibility, and scratch protection, the stickers retain their clarity and form over extended periods.

Our stickers arrive in custom sizes such as square, round, oval, and irregular shapes, we provide a smooth, professional finish for branding. Our stickers are best for electronic gadgets, product labels, and decorator use, ensure precision-produced epoxy stickers for durable performance.

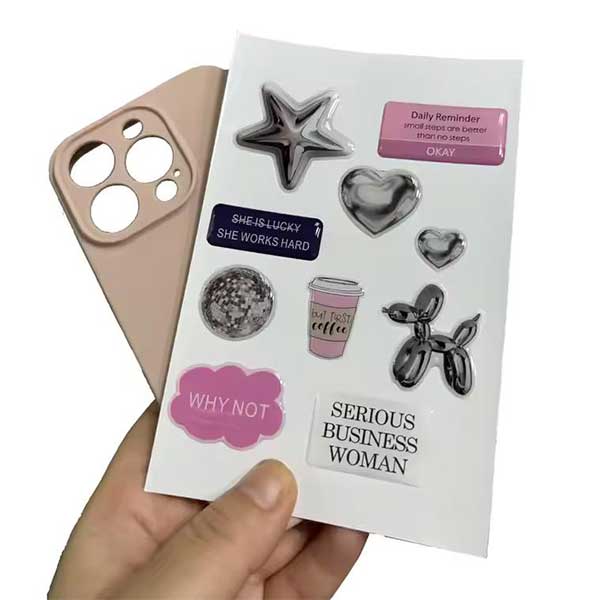

3D Dome Stickers

MSTR 3D dome stickers feature a crystal clear, scratch-resistant polyurethane coating, creating a dramatic 3D effect with a smooth, bubble-like look. The durable, non-yellowing surface provides bright color and lasting clarity to labels, giving a high-end, premium look.

Choose from various shapes and sizes, they provide a professional and eye-catching branding solution. Ideal for logos, product labels, and decorative applications, MSTR provides precise manufacturing and strict quality control for maximum performance.

Hologram Sticker

MSTR Hologram Stickers feature stunning holographic effects combined with scratch-resistance coating for long wearability, providing a lively, eye-catching touch for branding and security applications.

Our stickers designed with strong adhesion, water resistance and long-term durability in mind have maintained their original shine and lightness for many years, it’s perfect for product marking, brand security and promotion! Their wide variety of shapes and sizes. We also offer additional authentication and design features, it’s ideal for product marking, security and promotion!

Steps To Custom Dome Stickers

Design Creation

MSTR crafts a tailored digital design to align with brand identity, ensuring precision, visual impact, and market appeal.

Printing

Using advanced printing technology, MSTR produces high-definition graphics with vibrant colors on premium materials for a superior finish.

Die Cutting

MSTR applies precision die-cutting to create custom shapes and sizes of domed stickers, delivering flawless edges and exact dimensions.

Polyurethane Coating

We use a high-end polyurethane resin to form a tough, glossy 3D dome that gives effective branding and product protection.

Curing

MSTR’s engineered curing process reinforces durability to make dome stickers scratch resistant, UV resistant, and long-lasting clear.

Quality Inspection

Every our sticker undergoes rigorous quality control, guaranteeing perfect design execution, adhesion, and resilience before shipment.

Custom Domed Sticker Materials and Structure

MSTR offers fully customizable domed stickers with a variety of base materials and dome coatings to meet different branding and durability needs. We provide PET for thin and durable labels, PVC for flexibility on curved surfaces, and ABS/PC for impact resistance in outdoor applications. And for a luxurious metallic look, we offer chrome-plated and aluminum foil.

Our doming material includes PU, which is environmentally friendly, UV-resistant, and extremely durable for outdoor use, and epoxy, with glossy finish at low price. The standard thickness is 0.5mm to 3mm, with 1-2mm domed layers. Thin doming options under 0.5mm are available for compact logos and curved applications.

Custom Domed Sticker Color and Printing

MSTR offers fully customizable domed stickers with advanced printing and color matching options to enhance branding and visual appeal. We provide screen printing for rich, durable colors in mass production, UV digital printing for high-resolution gradients and small-batch customization, and thermal transfer printing for labels requiring barcodes or QR codes.

For a premium look, metallic plating and laser engraving can be done on domed metal stickers. Colour matching is precise PANTONE and RAL, with metallic finishes in gold, silver, and chrome for a mirror effect. Transparent and semi-transparent variations are available for LED indicator windows or backlight logos, offering versatility for a variety of applications.

Custom Domed Sticker Shape and Installation

MSTR offers fully customizable domed stickers with precision-cut shapes and versatile mounting options to suit a wide range of applications. We provide standard shapes such as round, square, oval, and rectangular, as well as custom laser-cut or die-cut shapes for intricate branding elements.

Our mounting choices include high-strength adhesive backing, i.e., 3M tape or foam adhesive, for secure bonding to smooth surfaces. For removable applications, we offer magnetic backing, and industrial nameplates can be reinforced with double-sided adhesive and rivet mounting for increased strength. Each domed sticker is constructed for precision, toughness, and perfection in integration with your product.

Custom Domed Sticker Additional Features and Application Scenarios

MSTR offers custom-designed domed stickers with increased strength and utility to various industries. Our domed labels are engineered to IP65 and IP67 dustproof and waterproofing certification, which is appropriate for industrial and outdoor applications. We use UV-stable finishes that are resistant to yellowing and color change over prolonged exposure to sunlight, ensuring long-term color consistency. For high-demand applications, we have chemical-resistant coatings, which protect from industrial solvents and cleaning chemicals, and scratch-resistant finishes for a blemish-free finish over time.

For function enhancement, we provide glow-in-the-dark effects for night visibility, reflective material for safety labels, and 3D transparent domed logos for high-end branding. Custom temperature- and light-sensitive color-changing effects are also available. These features make our domed stickers ideal for electronics branding, automotive and motorcycle decals (oil- and weather-resistant), household appliance panels (aesthetic and durable), high-end promotional gifts (premium branding), and safety signage (reflective or night-glow materials).