Designing food package labels is an important way to share crucial information with our dear customers. Nevertheless, any inaccuracies in doing so may actually risk our company legal repercussions, product recall, and even harm to the consumer. Food labels are more than aesthetically pleasing artwork designed to capture the consumer’s attention.

They carry out a very significant role of conveying personal information in a way that allows consumers to make well-informed buying decisions. Misbranded items, which are packages not in accordance with regulatory standards, may result in serious damage to the manufacturer.

Compliant and correct labels not only demonstrate good business ethics but also enable the business to thrive. Fortunately enough, creating regulation-compliant labels is an easy process that involves the addition of necessary information and compliance with established guidelines. This guide aims to equip readers with the knowledge required to prepare their own food package labels that are entirely compliant with all the current legal requirements.

1. What are Food Packaging Labels?

Food packaging labels consist of any written, printed, or graphic content found on the label, accompanying the food, or specially displayed close to the food. Such content is also utilized to promote the selling or disposal of the product. Their primary intent is to transfer significant information on the food to the user or consumer.

2. Why are Food Packaging Labels Important?

The graphic appearance of food packaging labels matters in getting the attention of shoppers and making them choose to purchase. The design of the label can instantly convey messages such as ‘green’, ‘affordable’, or ‘premium brand’.Incorporating vivid primary colors with a cheerful script font can tell consumers that the product is kid-friendly, and further product images add to capturing inquisitive buyers’ attention.

However, aside from presentation, the packaging food label serves an irreplaceable function of providing the public with essential information about issues regarding ingredients, nutrients, and calories. In addition to aiding the shopping consumer’s informed decision, labeling helps prevent any compliance violation that is necessitated by legislation.

For supermarket or restaurant suppliers, labeling is inevitable. Deviation from labeling requirements can invite severe penalties. Non-compliance can lead to the serving of an improvement notice by the authorities, which will specify contraventions and necessary improvements.

Prioritize correction of labeling defects within the time limit in order to avoid prosecution and charges; failure to do so could result in charges and possible prosecution, making food packaging labels an invaluable educational resource beyond legal requirements. They inform consumers about ingredients, nutrients and safe handling practices that contribute to overall health and wellbeing.

1) Nutritional Information

Labels have the important function of providing consumers with information on facts about fats, vitamins, minerals, and calories to help them make smart food choices. For those interested in managing weight or even disease like type 2 diabetes, that information becomes very important in allowing them to eat in moderation.

2) Food Safety

Food packaging labels offer more than nutritional data; they also contain useful details, including use-by dates, storage instructions and cooking guidelines that help prevent food poisoning. By following such guidance found on labels, risks associated with food poisoning and associated health concerns may be reduced substantially.

3) Allergen Awareness

Since more people have gained awareness about allergens, it is now even more important for proper food labeling to help recognize possible allergens such as peanuts, milk, eggs, etc. Proper indication of allergens through labeling saves people with allergies from facing critical situations, further highlighting the relevance of proper labeling in saving one from fatal allergic reactions.

4) Reducing Food Waste

In addition to safety and health, food labeling also helps in cutting down food wastage by maintaining consumers’ consciousness of the product’s freshness as well as its ability to be consumed or not. By the acquisition of knowledge about date labeling and storage, consumers can help in cutting down wasteful consumption of food, which goes a long way in minimizing the extensive rate of food wastage.

5) Ethical and Environmental Considerations

Labels can inform consumers about environmental and ethical concerns associated with products, such as organic or fair-trade production. By outlining production methods and sourcing practices, labels enable value-based purchasing decisions which support sustainable food production practices.

Additionally, country of origin information can help increase consumer trust and ensure payment for quality ethically produced goods – helping producers reach maximum profitability.

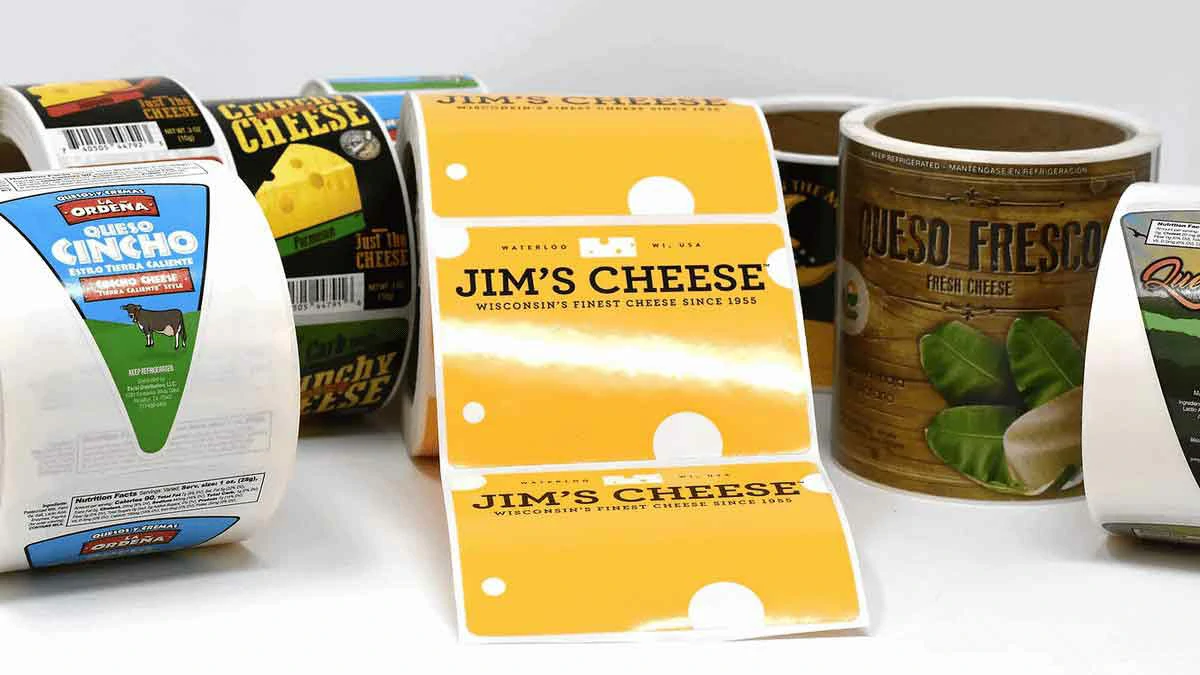

3. Food Packaging Labels Design Process

An effective label design process ensures that each food package conveys the appropriate message, meets legal requirements and performs optimally in retail and logistics environments.

Brand owners and food manufacturers who understand each design stage can more efficiently collaborate with packaging suppliers and avoid costly rework before mass printing.

1. Information Collection and Regulatory Planning

The first stage focuses on collecting all necessary product data and identifying applicable regulations. Key steps include:

- Confirming target markets and labeling standards (e.g., FDA, EU, GB).

- Gathering accurate product information: ingredients, nutritional values, allergen statements and storage instructions.

- Determining label size and placement according to packaging type (pouch, bottle, box or film).

- Establishing the appropriate languages required for export markets.

An accurate data set at this stage helps prevent later revisions and ensures that the design meets both branding and compliance requirements.

2. Content Drafting and Graphic Layout

Once all information has been confirmed, design and layout work begins. Professional label artwork should strike an equilibrium between visual appeal, readability and regulatory precision:

- Definition of information hierarchy — Product name, Brand name, mandatory data fields and secondary details should all be clearly articulated.

- Apply appropriate font styles and sizes (minimum of 1.2mm font for legal text in most markets). Maintain strong color contrast between background and text for legibility purposes.

- Reserve designated areas for variable data such as barcodes, batch codes and expiry dates.

- Menager Be sure to incorporate certification marks and QR codes with ample white space for accurate scanning accuracy.

Designers should utilize vector-based software (AI, EPS and PDF) in order to maintain sharpness and accurate color reproduction during printing.

3. Artwork Review and Pre-Press Preparation

Failure to do so could result in charges and prosecution, making food packaging labels even more crucial for individual health and well-being than legally mandated requirements alone. By informing consumers about ingredients, nutrients and safe handling procedures they can achieve greater health and well-being overall.

Before printing, a structured review process must take place to identify layout or compliance errors that could compromise its content and results in printout errors.

Checking that all mandatory fields are present and formatted properly, reviewing text translation quality for multilingual labels, running a color proof to validate appearance, and making sure barcodes adhere to GS1 standards for readability are the keys to successful printing projects.

Corrections made at this stage will likely be less costly than changes after plate production or mass printing has begun.

4. Proofing and Sample Validation

A physical or digital proof allows both design and quality teams to inspect the final layout under real production conditions. Typical validation criteria include:

- Alignment of text and graphics within the cut line.

- Correct color matching against approved Pantone or CMYK references.

- Adhesive performance on the actual packaging surface.

- Resistance tests for moisture, temperature and abrasion (especially with frozen or chilled foods).

Proof approval should be formally documented before initiating bulk production.

5. Printing and Production Control

During mass production, consistent color, registration, and finishing quality are crucial. Key control points:

- Continuous color monitoring using spectrophotometers or densitometers.

- Periodic sampling for barcode readability and print registration accuracy.

- Verification of adhesive uniformity and surface finish (matte, gloss, or textured).

- Random inspection based on ISO quality sampling standards.

Maintaining precise control at this stage ensures that every batch of labels meets both quality and compliance expectations.

6. Post-Production Handling and Logistics

Once printed, labels must be stored and transported under strict control to preserve quality:

- Temperature and humidity within specified ranges to prevent curling or adhesive degradation,

- protection from direct sunlight and dust during storage

- Packaging into shrink-wrapped rolls or flat sheets for efficient export logistics are key requirement of success.

Clear labeling on outer cartons containing product codes, roll direction information and quantities expedites packing or filling processes.

An effective label design process combines regulatory compliance, aesthetic design, and manufacturing precision into one cohesive process. By adhering to a structured path from data collection through proof approval and production control, brands can reduce risks while simultaneously maintaining consistency across their label production line; every label leaving the factory will be both compliant and market-ready!

4. Essential Elements & Compliance of Food Packaging Label

Food businesses have a legal obligation to label every food product they produce. The details that need to be placed on the label vary depending on the area and the food legislation controlling the item. Adherence is critical when selling to the end-consumer to avoid potential outcomes for both the consumer and the business.

1) Mandatory Elements Required on Food Packaging Labels

Components on food packaging labeling that are essentially necessary to incorporate, based on where one lives and exports their food, include:

- Food name/description

- List of ingredients

- Allergen information

- Nutritional details

- Best-before or use-by dates

- Storage instructions

- Preparation and handling guidelines

- Lot identification for traceability

- Country of origin

- Contact information, including producer/agent name and address

- Weight or measurement details

This comprehensive information can be displayed on the main label panel, with the food name and quantity on the front and manufacturer details, ingredient statement, and nutrition facts on the back panel as specified.

2) Key Global Regulations Overview

Below is an outline of major regulatory systems related to international food trade:

| Region | Primary Regulation | Highlights | Professional Recommendation |

| United States | FDA 21 CFR Part 101 | Nutrition Facts panel, Allergen Labeling Act (FALCPA), origin declaration | Minimum font height: 1/16 inch for mandatory information. |

| European Union | Regulation (EU) No 1169/2011 | Nutrition format standardization, multilingual requirements, font x-height ≥ 1.2 mm | Dual-language labeling (e.g., English + local language) improves compliance. |

| China | GB 7718-2011 / GB 28050-2011 | Mandatory Chinese text, ingredient order by weight, allergen indication | Compliance requires correct font type and punctuation format. |

Compliance Recommendation: Prior to mass production, label layouts should be reviewed against regional standards for information order, font size, contrast, and legibility.

3) Optional but Recommended Label Information

Food brands frequently include additional information that increases transparency and consumer trust beyond mandatory data:

- Certifications: Organic, Halal, Kosher, Vegan, Non-GMO, FSC and ISO (etc).

- Sustainability Marks: Recyclable, biodegradable and compostable production with CO2-neutral manufacturing practices.

- Nutritional or Functional Claims: “No added sugar,” “Gluten-free,” and “High protein levels”.

- Digital Traceability: QR and RFID codes providing origin verification or production batch information are effective tools for digital traceability.

Note: Voluntary claims must be honest and in line with the product’s actual characteristics; any unsupported marketing terms could violate advertising or labeling regulations in export destinations.

4) Frequent Compliance Errors and Preventive Measures

| Common Issue | Preventive Measure |

| Allergen not highlighted or missing | Use consistent formatting and bold type for declared allergens. |

| Text smaller than minimum legal size | Follow regional font-size requirements (EU ≥ 1.2 mm, FDA ≥ 1/16 inch). |

| Barcode positioned too close to edge | Maintain minimum clear area to prevent scanning errors. |

| Inconsistent measurement units (g vs oz) | Match measurement systems to destination market standards. |

| Color contrast too low for legibility | Ensure at least 70% contrast between background and text. |

Pre-print compliance checklists and artwork review processes help reduce these errors while maintaining regulatory conformance.

5) Role of Label Compliance in Packaging Production

Compliance is an essential step in packaging production. Accurate and compliant labeling protects both the manufacturer and their brand by:

- Avoiding shipment delays and import rejections.

- Provide clear consumer information across regions.

- Support product traceability and recall systems.

- Enhance brand integrity and global acceptance.

Compliance verification should precede material selection, printing and mass production to ensure that all packaging components comply with legal and safety requirements.

5. Types of Food Packaging

Food packaging comes in many shapes and forms, each designed to protect its contents while extending shelf life and drawing attention to it on store shelves. Understanding the characteristics of various packaging types helps determine the ideal label material, adhesive material and printing method for each application.

1. Rigid Packaging

Rigid packaging refers to containers such as glass jars, metal cans and hard plastic bottles which provide superior protection from external pressure and are widely used for sauces, beverages, canned food and dairy products. Due to their firm surfaces and precise alignment requirements, rigid containers require labels with strong adhesion for effective storage and transport; paper or film labels featuring glossy or matte lamination are typically applied over rigid containers to provide added durability during storage and transport.

2. Semi-Rigid Packaging

This category encompasses thermoformed trays, clamshells and some composite containers made from semi-rigid materials such as thermoformed plastic. Such packaging provides both structural integrity and lightweight portability – ideal for fresh produce, ready-to-eat meals and bakery goods. Labels used on semi-rigid packaging must be flexible enough to conform to curved surfaces without wrinkling or peeling. Film-based materials such as polypropylene (PP) or polyethylene (PE) are ideal choices for this purpose.

3. Flexible Packaging

Flexible packaging is one of the fastest-growing formats in the food industry, covering pouches, sachets, wraps, and films. It is lightweight, space-efficient, and suitable for high-speed production lines. Because flexible packaging often undergoes bending and friction during filling and transportation, labels need to be resistant to tearing and moisture. Pressure-sensitive film labels or direct printing on the film surface (such as in-mold or heat transfer) are often preferred to maintain both aesthetics and durability.

4. Aseptic and Vacuum Packaging

Used for long-shelf-life or perishable foods, aseptic and vacuum packaging prevents contamination and oxidation by isolating products from external air. The labeling materials for these applications must withstand sterilization, temperature variation, and extended storage periods. Synthetic film labels with strong adhesives are recommended to ensure secure bonding even under high heat or cold-chain conditions.

5. Eco-Friendly and Sustainable Packaging

Sustainability has become a central concern for modern food brands. Eco-friendly packaging options include recyclable paper boxes, compostable films, and bio-based plastics such as PLA. Labels for sustainable packaging should ideally match the recyclability or biodegradability of the base material. Using water-based inks, non-toxic adhesives, and FSC-certified paper not only supports environmental goals but also enhances the brand’s responsible image in global markets.

In today’s competitive food industry, the type of packaging determines more than just appearance; it defines how well the product survives distribution, how consumers perceive the brand, and how efficiently labeling processes can be managed. Selecting the right combination of packaging and label materials ensures durability, compliance, and consistent presentation from production to retail shelves.

6. Food Packaging Label Cost Structure & Optimization Tips

Understanding how label costs are formed is essential for any food brand or packaging buyer aiming to achieve both quality and efficiency. A label is more than just a printed design — it represents a combination of materials, technology, and craftsmanship. Recognizing these cost factors allows brands to plan budgets realistically and identify opportunities to optimize without sacrificing performance or compliance.

1) Label Cost Structure

The total cost of producing a food packaging label is influenced by several interconnected elements. Among them, the choice of material and printing method usually has the greatest impact. Paper labels are generally more economical and well-suited for dry food or short shelf-life products, while film or foil labels cost more but offer better resistance to moisture, oil, and temperature changes, ideal for beverages, frozen food, and premium goods.

Printing technology also plays a key role. Digital printing requires no plate setup, making it suitable for small batches or frequent design changes, though the unit price may be slightly higher. In contrast, flexographic and gravure printing involve setup costs but deliver much lower unit prices for large production runs. The balance between these methods depends on order volume and the desired finish.

Other cost contributors include adhesives, coatings, finishing, and logistics. Specialty adhesives such as freezer-grade or removable versions add value but increase material costs. Finishes like matte lamination, embossing, or foil stamping enhance visual appeal and durability but also require additional steps in production. Even packaging and transportation, such as label roll orientation or moisture-resistant packing, play a role in determining final pricing, especially for export orders that must withstand long shipping periods.

In short, label cost is a combination of design complexity, performance expectations, and production efficiency. A clear understanding of these cost components helps avoid unrealistic quotations and ensures that every dollar spent contributes to visible quality and brand consistency.

Each printed label involves multiple contributing elements that collectively determine the final unit price:

| Cost Element | Description |

| Design & Artwork Preparation | Includes layout creation, dieline setup, text formatting, and color separation for printing. |

| Printing Plates / Setup Costs | Applicable to flexographic or offset printing; usually one-time per design version. |

| Material Selection | Substrate choice (paper, film, foil, or biodegradable materials) has the greatest impact on overall cost. |

| Ink & Finishing | Type of ink (standard, UV, water-based) and finishes such as matte, gloss, embossing, or foil stamping. |

| Adhesive Type | Permanent, removable, freezer-grade, or high-tack adhesives influence both cost and application performance. |

| Quantity (MOQ) | Larger volumes lower per-unit cost by distributing setup expenses across more pieces. |

| Quality Control & Testing | Costs for proofing, color calibration, and sample validation to ensure consistent output. |

| Logistics & Packaging | Label winding direction, core size, carton packaging, and international shipping fees. |

Material and print process typically account for 60–70% of total label cost, while finishing and quality control represent 15–25%, depending on complexity and production volume.

2) Optimization Tips

Cost optimization does not mean cutting corners; it means making smart choices that maintain both functionality and aesthetics. The most effective way to reduce expenses is to align label design, material selection, and production planning early in the project. Choosing the right printing process for the order size is the starting point. Digital printing is cost-effective for prototypes and small runs, while flexographic printing becomes more economical as volume increases.

Material selection offers another major opportunity. Lightweight or thinner substrates can significantly reduce cost and waste, provided they still meet the product’s durability requirements. In many cases, brands can achieve a premium look without expensive embellishments by using textured paper or high-resolution printing instead of metallic foil. Streamlined designs not only print faster but also minimize registration errors and color deviations, further saving rework costs.

Consolidating multiple product variations into a single production run is also a practical approach. Similar label sizes or shared color schemes allow efficient use of printing plates and reduce setup time. When product demand is stable, slightly increasing the print quantity per batch can lower the unit price while maintaining supply continuity.

Sustainability and cost efficiency can go hand in hand. Recyclable materials, water-based inks, and eco-friendly coatings are becoming more affordable as technology advances. Adopting these options not only lowers environmental impact but also enhances brand perception in markets that value responsible production.

Ultimately, effective cost management in label production depends on smart coordination between design, material choice, and manufacturing scale. When each step is planned with both performance and practicality in mind, labels become not only compliant and visually appealing but also cost-efficient and sustainable, delivering the best value for every brand.

7. How to Partner with a Reliable Food Packaging Label Manufacturer?

You can build long-term value through trust, quality, and collaboration by cooperating with a reliable food packaging label manufacturer.

1. Choosing a Partner That Supports Brand Success

Finding the right label manufacturing partner is more than simply comparing prices. A reliable supplier brings technical expertise, consistency, and strategic guidance that directly influence a brand’s performance in the market.

For food manufacturers and brand owners, selecting a professional label partner means gaining a team that understands regulatory compliance, material behavior, and visual branding, ensuring that every package communicates trust and quality.

2. Establishing Transparent and Effective Communication

The foundation of a strong partnership begins with open communication. Before any project starts, both sides should exchange clear details about target markets, packaging types, label dimensions, and preferred materials.

Sharing information about the product’s application environment, such as frozen, chilled, or ambient storage, enables the manufacturer to recommend the most appropriate adhesive, substrate, and printing process. Effective communication at the early stage prevents costly revisions and ensures that every label performs as expected throughout its lifespan.

3. Evaluating Technical Strength and Quality Assurance

Technical capability and quality control are critical factors in determining a manufacturer’s reliability. An experienced supplier operates under standardized production procedures and uses certified raw materials that meet international standards. Reliable partners provide color proofs, material samples, and detailed testing reports before full production. Facilities equipped with advanced color calibration, barcode verification, and adhesion testing systems demonstrate the manufacturer’s ability to deliver consistent, compliant, and high-quality labels.

4. Looking for Flexibility and Scalable Production

Food brands often deal with multiple product variations and seasonal packaging changes. A dependable label partner must be able to adjust production volumes, maintain color consistency across batches, and handle both prototype runs and mass production efficiently. Flexibility in production scheduling and scalable capacity ensure that packaging updates or new launches are completed on time without compromising quality or design accuracy.

5. Assessing Service Reliability and Logistical Support

Beyond printing, service reliability and logistical coordination play a major role in a successful partnership. On-time delivery, export packaging expertise, and efficient communication reflect the manufacturer’s professionalism. Experienced suppliers in international trade understand documentation requirements, labeling regulations, and export compliance, which helps global buyers avoid customs issues and shipment delays. Consistent service support indicates a commitment to long-term cooperation rather than short-term transactions.

6. Building Trust and Growing Together

A productive partnership is built on mutual trust and shared development. The most reliable manufacturers go beyond producing labels; they actively support customers with insights into material innovation, cost optimization, and sustainable packaging solutions. Working closely with such partners enables brands to stay competitive, reduce risks, and enhance both product presentation and market performance.

7. Creating Value Through Collaboration

Partnering with a dependable label manufacturer means gaining more than a supplier. It means extending a brand’s production and quality capabilities with professional support. Through collaboration, every label becomes a reflection of product integrity, safety, and brand identity, ensuring that what reaches consumers is consistent, compliant, and visually compelling from start to finish.

8. Exploring the Future of Food Packaging Labels

1. The Rise of Smart Label Technology

The future of food packaging labels is moving toward a new era of digital integration and intelligent interaction. Smart labels that incorporate technologies such as QR codes, RFID, and NFC are transforming the way consumers and businesses connect with products. By scanning a label, consumers can instantly view ingredient details, allergen information, nutritional data, or even trace the origin of raw materials. For manufacturers and distributors, these technologies enable real-time tracking, inventory control, and product authentication, making supply chains more transparent and efficient.

As digital engagement becomes more common, many food brands are adopting smart labels to enhance communication with their customers. These interactive labels can link to recipe tutorials, sustainability reports, or the brand’s origin story, creating deeper trust and emotional connection. Smart labeling not only adds convenience but also plays a growing role in compliance and traceability, helping brands meet the increasingly strict requirements of global food regulations.

2. Sustainability as the Core of Future Development

Environmental responsibility has become a defining direction for the packaging industry. Food brands are now rethinking materials and processes to reduce waste and carbon emissions, and labels are a vital part of this transformation. Recyclable paper labels, biodegradable films, and bio-based plastics such as PLA are gradually replacing traditional petroleum-based materials.

Water-based inks and non-toxic adhesives are being widely used to improve recyclability and reduce pollution during production. The growing adoption of mono-material packaging, where both the label and container share the same base polymer, makes recycling easier and more efficient. Lightweight materials are also helping to reduce transportation emissions while maintaining durability and print quality.

3. The Integration of Technology and Environmental Awareness

The future of food labeling lies in the integration of intelligence and sustainability. Labels will carry digital traceability features while being environmentally friendly in both composition and production. International retailers and certification bodies are encouraging the use of eco-labels that clearly communicate recycling instructions and carbon footprint data to consumers.

In the years ahead, food packaging labels will evolve from being simple identifiers into intelligent tools that support transparency, strengthen brand reputation, and demonstrate environmental commitment. For brands seeking long-term growth, embracing smart and sustainable labeling is not only a responsible choice but also a powerful step toward greater competitiveness in the global market.

9. Food Packaging Label FAQs

Below are some frequently asked questions about food packaging labels:

1) What Purpose Does Food Labelling Serve?

Food labeling is necessary to give consumers helpful information about ingredients, nutrition facts, allergens, and storage instructions for a product in order to allow them to decide.

2) How Do Food Packages Affect the Environment?

Certain food packaging matter, such as disposable plastic, may cause harm to the environment. However, the development of environmentally friendly food packages attempts to reduce this damage.

3) What are the Key Food Labeling Ingredients Made Up of?

Some key points of food labeling are product name, list of ingredients, nutrition, allergen statement, weight, and name and address of manufacturer or packer.

4) How does Food Labelling Influence Consumer Choice?

Food labelling can influence consumer choice by emphasizing health benefit statements, labels and certifications and the delivery of nutritional information so that individuals make proper choices appropriate for their personal likes and nutrition requirements.

5) What is the Government Role in Food Packaging and Labelling?

Government regulations are what ensure packaging of food conforms to safety levels and labeling provides correct and clear information in order to safeguard consumers’ interests.

10. Conclusion

Food labeling and packaging play basic functions that, even though behind the scenes, are essential in a way that they help guarantee freshness, safety, and impact customer decision. As much as the food industry has transformed to meet new consumers’ needs for the current generation, food packaging and labeling uses still remain at the core of guaranteeing food safety, quality, and satisfaction to the customers.

Taking the benefit of food labeling and green packaging, the food industry can be directed towards meeting the evolving demand and requirement of its advanced consumers, ensuring for a friendly relationship between industry and consumer demand.

Leave A Comment