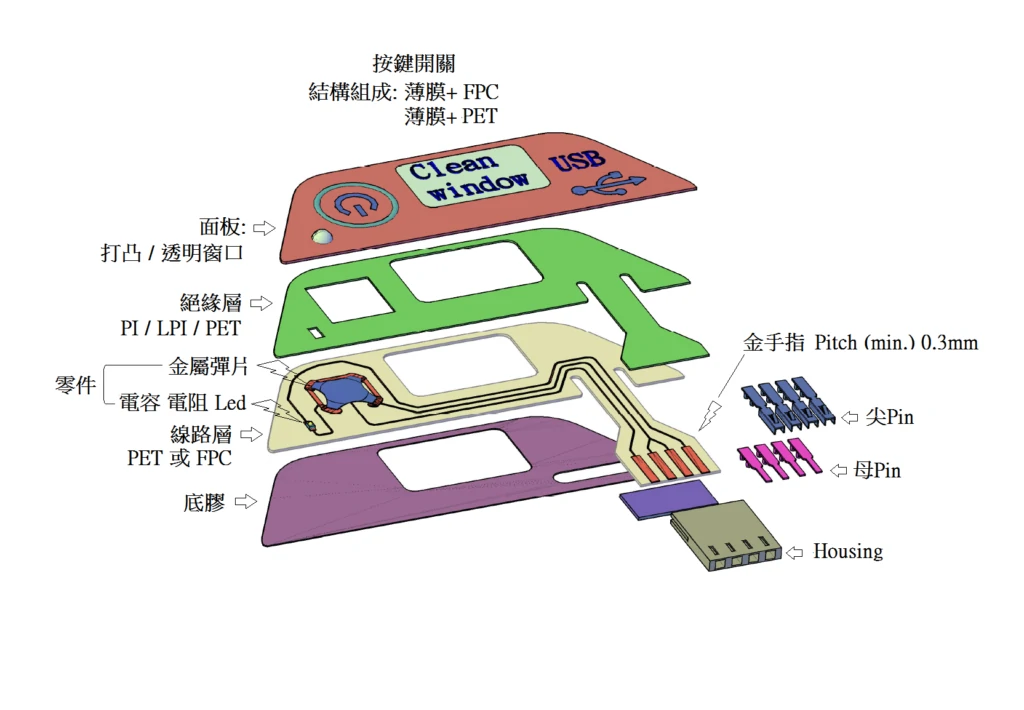

Compared to the traditional membrane switches with silver paste printed flex as the circuit layer, the FPC membrane switch is quite different. The FPC membrane switch is constructed of Polyimide copper etched FPC circuits with copper flex traces that possess greater durability and stability.

With an amazing high temperature resistance of up to 280degC, delicate circuitry with 0.5mm output spacing, low electrical resistance, high conductivity and stable performance characteristics – such as its remarkable high temperature resistance – this switch boasts remarkable reliability and durability beyond that of standard membrane switches. Furthermore, its versatile configuration enables direct soldering of active and passive components directly into its configuration further expanding its usefulness and applicability.

1. What is an FPC Membrane Switch?

An FPC membrane switch is a type of flexible electronic switch that combines membrane keypad design with flexible printed circuit (FPC) as its electrical layer. It combines multilayer membrane design with precision and conductivity of flexible circuitry to produce an ultra-reliable yet space-saving user interface solution.

Each key or button on the surface corresponds with a conductive circuit path etched onto an FPC layer below. When a user presses a key, their top conductive layer makes contact with this circuit through an intermediary layer – thus completing electrical connections and signaling the control system.

FPC membrane switches offer higher conductivity, longer lifespan, and improved heat resistance compared to their printed silver circuit counterparts, making them the ideal solution for complex electronic products that demand both thin profile designs and high reliability.

Common uses for flexible circuit boards include medical instruments, industrial control panels, automotive dashboards, consumer electronics and aerospace systems. Their versatility allows integration into curved surfaces or compact assemblies where rigid circuit boards would otherwise not fit.

FPC membrane switches represent the next-generation of traditional membrane keypads, providing increased durability, signal stability and design versatility while remaining lightweight and low profile.

2. How Does an FPC Membrane Switch Operate?

An FPC membrane switch operates by completing and breaking an electrical circuit through user interaction. The switch is built from several functional layers that work together to create a responsive and reliable input system.

Typically, the structure includes a top graphic overlay, an adhesive layer, a spacer layer, a flexible printed circuit (FPC) layer, and a bottom adhesive layer that secures the switch to the product housing.

When a user presses a key on the surface, the pressure causes the top conductive contact on the FPC layer to touch the bottom circuit. This action closes the circuit and sends an electrical signal to the connected control unit or device. As soon as the user releases their key, the spacer layer allows the top layer to return to its previous position, breaking the circuit and ceasing signal flow.

FPC layers consist of copper traces etched onto flexible polyimide films for improved electrical performance and durability. When compared with traditional membrane switches that rely on printed silver ink circuits, FPC design offers lower contact resistance, higher precision, and enhanced thermal stability.

Some advanced designs also include metal domes or tactile switches to provide a clear feedback “click” when pressed, improving the user experience. Others may incorporate LEDs, resistors or sensors directly onto an FPC for added functionality.

An FPC membrane switch converts a simple mechanical press into an accurate electronic signal, making it perfect for compact devices requiring thin, lightweight control interfaces with long-term durability.

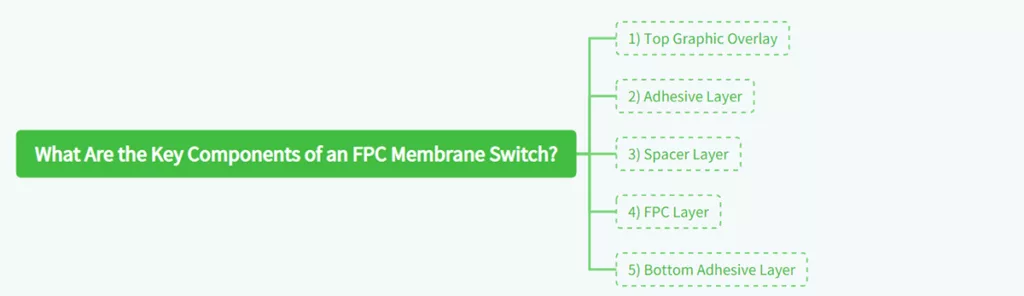

3. What are the principal components of an FPC membrane switch?

These advanced switches consist of principal components carefully designed to offer smooth performance and a user-friendly interface. From the top graphic overlay with symbols and keys to the FPC layer with the important printed circuits, each component plays an important role in offering a superior user experience.Let’s delve deeper into the intricate layers that make up an FPC membrane switch and discover the magic they bring to your devices.

1) Top Graphic Overlay

This layer provides a visual interface for the user, showing the keys and symbols.

2) Adhesive Layer

This secures the graphic overlay to the FPC layer.

3) Spacer Layer

This layer helps keep the top layer separate from the bottom circuit layer, preventing accidental activation.

4) FPC Layer

The core functional part of the switch contains the printed circuits that close the electrical circuit when a key is pressed.

5) Bottom Adhesive Layer

This layer secures the entire assembly of the device or substrate.

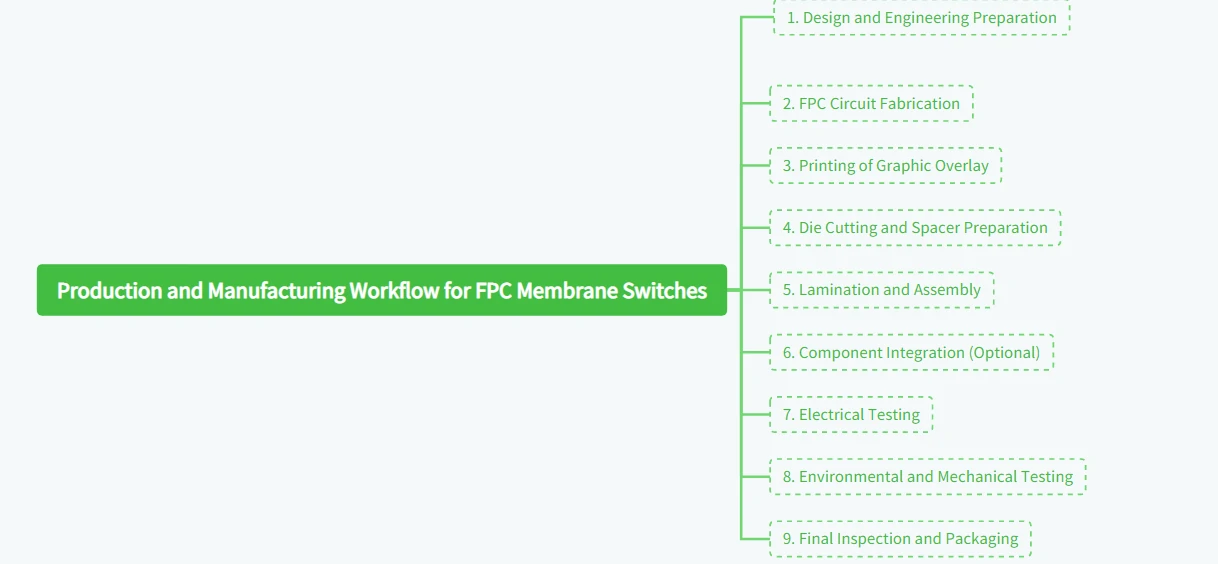

4. Production and Manufacturing Workflow for FPC Membrane Switches

FPC membrane switch manufacturing requires a precise combination of flexible circuit fabrication, lamination and assembly processes that must be accomplished meticulously for maximum electrical performance, durability and visual quality. Below is an outline of a general production workflow used by most professional manufacturers.

1. Design and Engineering Preparation

Starting with customer specifications, engineers develop detailed product designs using CAD software. Engineers then prepare circuit layouts, layer stack drawings and mechanical outlines using these drawings; specifying parameters like key positions, trace widths, connector types and interface locations before producing prototype or small batches as testing ground for accuracy and tactile performance.

2. FPC Circuit Fabrication

Flexible Printed Circuit (FPC) production occurs on polyimide film using copper foil. After being etched to produce desired conductive traces and contact pads, the surface is protected using protective coatings such as coverlay or solder mask to avoid oxidation and short circuiting issues. Additional surface treatments like ENIG (Electroless Nickel Immersion Gold) or OSP (Organic Solderability Preservative) may also be applied to further improve conductivity and solderability quality.

3. Printing of Graphic Overlay

Silk-screen or digital printing methods are used to print the top graphic overlay of polycarbonate or polyester films with colors, icons, logos and symbols that define its appearance – including colors, icons logos and symbols. Once printed, protective coatings such as matte, gloss or UV resistant finishes are applied afterward for enhanced durability and scratch resistance.

4. Die Cutting and Spacer Preparation

All layers including overlay, adhesive sheets, and spacer layers are precision die-cut or laser cut for accurate dimensions. Spacer layers contain openings which only make contact when keys are pressed – this precision of cutting is essential to maintaining correct key travel and tactile feel.

5. Lamination and Assembly

Layers must be meticulously aligned and laminated together under cleanroom conditions to ensure proper switch operation, typically starting with graphic overlay – top adhesive – spacer – FPC circuit – back adhesive. Each layer must adhere within tight tolerances in order for lamination to take place properly, with air bubbles or dust particles removed during lamination to maintain clarity and prevent false contacts from being made during switch operation.

6. Component Integration (Optional)

Some FPC membrane switches come equipped with metal domes, LEDs, resistors or sensors built directly into their circuit. Metal domes provide tactile feedback while LEDs enable backlighting or indicator functions. These components are positioned and fixed using automated placement machines or manual alignment depending on complexity.

7. Electrical Testing

After assembly, the finished switches undergo 100% electrical testing. Each key is pressed to verify conductivity, contact resistance, and proper signal output. Checks of open circuits, short circuits and uneven key responses must be performed regularly for optimal performance. Testing equipment may simulate thousands of actuation cycles to verify durability and reliability.

8. Environmental and Mechanical Testing

High-quality FPC membrane switches are rigorously tested under various environmental conditions to ensure they function reliably, such as temperature cycling, humidity aging, vibration testing and bend resistance. Manufacturers also conduct tactile force and lifecycle tests – sometimes exceeding one million presses per key – in order to guarantee long-term performance.

9. Final Inspection and Packaging

After passing all tests, switches undergo a visual inspection to inspect surface quality, printing alignment, connector position and lamination integrity. Approved units are cleaned, packed in protective films and sealed anti-static or moisture proof packaging before each batch is labeled with traceability information including lot number and inspection record number.

5. What Are the Advantages of FPC Membrane Switches?

Are you looking to increase the performance and user experience of your product? FPC membrane switches offer numerous advantages over rigid circuits. From being flexible and durable, to compact size and customizability – FPC membrane switches offer innovative solutions for applications demanding reliability.

1) Flexibility

One of the primary advantages of FPC membrane switches is their versatility; making them ideal for various applications where rigid circuits would not suffice.

2) Durability

FPC switches can withstand harsh environmental conditions such as fluctuating temperatures, humidity levels and mechanical stresses without succumbing to wear-and-tear damage.

3) Space-Saving

The thin profile of FPC membrane switches makes them ideal for devices where space is limited.

4) Light Weight

Rigid tubes tend to add significantly less weight to a device than their flexible equivalents, contributing less overall.

5) Customization

FPC membrane switches’ design and geometry can easily be engineered to meet desired application requirements.

6. What are the common uses of FPC Membrane Switches?

These new elements have infiltrated a wide range of industry, from consumer goods and medical devices to controls, industrial applications, and automobiles, and, yes, even aerospace technology.

From enhanced functionality of medical equipment, enhanced user experience in consumer devices to delivering high-precision control in mission-critical aerospace use, FPC membrane switches are resistant to abuse and long-lasting in varied industry application.

1) Medical Devices

Used in various diagnostic and monitoring equipment due to their durability and reliability.

2) Consumer Electronics

Commonly found in remote controls, gaming consoles, and handheld devices.

3) Industrial Controls

Employed in machinery and equipment control panels for their robustness and ease of use.

4) Automotive

Integrated into dashboards and control systems for a sleek and functional interface.

5) Aerospace

Applied in cockpit instruments and other control systems of prime importance because of their lightness and space efficiency.

7. How to Design an FPC Membrane Switch?

Starting out on the design journey of an FPC membrane switch involves adopting a strategic methodology to achieve the best functionality and performance.

By going through a precise process of requirement analysis, schematic design, selection of materials, building of a prototype, extensive testing, large-scale production, and hassle-free installation, you can create an error-free and efficient membrane switch that is tailored to the special needs of your application. Join us in the realm of innovative design and bring your concept into existence with precision and perfection.

1) Requirement Analysis

Begin by understanding the specific needs of the application, including the interface layout, type of user interaction, and environmental conditions.

2) Schematic Design

Create a circuit design that meets the electrical requirements. This should include the placement of keys and their connections.

3) Material Selection

Select materials suitable to the operating environment, including adhesives, circuit materials and overlays that will withstand its conditions.

4) Prototype Development

Develop a prototype to test the design. This step allows you to make any necessary adjustments before mass production.

5) Testing

Conduct rigorous testing to ensure the switch performs under various conditions, including pressure, temperature, and humidity tests.

6) Production

After finalizing the design and its test, proceed with mass production so that proper quality control procedures are implemented.

7) Installation

Finally, the FPC membrane switch is mounted into the end product such that it fits correctly and operates as required.

8. FPC Membrane Switch Troubleshooting and Common Problems

Annoying as it is to experience issues with your FPC membrane switch, fear not, since addressing common problems through troubleshooting can lead to successful fixes. Sticky keys, erratic operation, wear, and adhesive failure, all are issues that can be fixed by aggressive inspection and specially targeted remedial action. By requiring circuit breaks, environmental condition testing, maintenance testing, and adhesives compatibility testing, you can make your FPC membrane switch operate smoothly and last longer, which will allow you to deliver a better user experience. Let’s fix these issues together and return your switch to optimal performance.

1) Non-Responsive Keys

If certain keys are not working, check for circuit breaks or poor connections. This can often be resolved by inspecting the FPC layer for any visible damage.

2) Intermittent Functionality

Sporadic functioning of the switch could be due to environmental conditions like temperature or humidity. Use materials for it that are appropriate to operating conditions.

3) Wear and Tear

Wear can build up over time in the graphic overlay and other layers, particularly where usage is high. Conducting regular inspections and maintenance to extend its lifespan.

4) Adhesive Failure

If the switch is peeling or not sticking securely to its substrate material, check that the adhesive used is suitable.

9. How Do You Keep an FPC Membrane Switch?

To ensure the life and top performance of your FPC membrane switch, a preventive maintenance practice is necessary. By observing easy but practical habits such as regular cleaning using mild cleaners, keeping it from being exposed to aggressive environments, making occasional inspections for wear and tear, and discouraging abusive handling by operators, switch life can be prolonged and the likelihood of future problems minimized.

Remember that a small amount of maintenance will go a long way in making your FPC membrane switch continue to work and be reliable.Let’s keep your switch in top shape for error-free operation and enhanced user satisfaction.

1) Regular Cleaning

Keep the surface clean and free of debris. Use non-abrasive cleaning agents to avoid damaging the overlay.

2) Avoid Extreme Conditions

Although FPC membrane switches are durable, avoiding excessive exposure to extreme temperatures, humidity, and mechanical stress can extend their life.

3) Periodic Inspection

Regularly inspect the switch for signs of wear and tear, adhesive failure, or circuit damage. This allows for early intervention before any major issues arise.

4) Gentle Use

Request users to apply suitable pressure when they switch on the switch in order not to exert excess pressure on the layers and circuits.

10. Cost and Pricing Factors for FPC Membrane Switches

The cost of an FPC membrane switch depends on multiple engineering, material, and production variables. Understanding these factors helps buyers prepare accurate budgets and communicate design priorities clearly with manufacturers.

1. Circuit Design Complexity

The most significant cost driver is the complexity of the FPC circuit. Designs with more traces, finer line widths, or multiple connection points require advanced etching and alignment processes. If the circuit includes multiple layers or requires shielding, impedance control, or high-density connectors, the manufacturing cost increases accordingly. Simpler circuits used for basic control panels are usually less expensive than multi-zone or sensor-integrated layouts.

2. Material Selection

Material choice strongly influences both performance and pricing.

- FPC substrate: Polyimide film is the standard base material. Thicker or high-temperature grades are more costly but improve stability.

- Conductive traces: Copper is most common, while gold plating or silver paste for special applications increases cost.

- Overlay material: Polyester (PET) is economical and flexible; polycarbonate (PC) offers better clarity and toughness but is more expensive.

- Adhesives: 3M high-performance pressure-sensitive adhesives add reliability but cost more than standard types.

The right combination balances durability, flexibility, and cost.

3. Printing and Surface Finishing

The appearance and protection of the top overlay also affect pricing. Full-color silk-screen printing or digital UV printing with precise registration requires more production time. Adding protective coatings such as hard coat, matte texture, or UV resistance enhances product lifespan but slightly raises cost. Labels with special visual effects like metallic ink, embossing, or transparent windows are priced higher than standard overlays.

4. Tactile Components and LED Integration

Switches that include metal domes for tactile feedback, LED backlighting, or indicator windows involve extra materials and assembly steps. Metal domes must be precisely positioned and adhered to the contact points, while LEDs require soldering and circuit modifications. Such enhancements can increase the total unit cost by 10–30 percent, depending on design density and complexity.

5. Connector Type and Assembly Method

The type of connector used to link the switch to the main control board also influences cost. Common options include ZIF connectors, pin headers, or custom cable assemblies. ZIF connectors are widely preferred for reliability but require precise FPC tail dimensions, adding a minor cost for precision cutting and testing. Additionally, manual assembly for small orders is more expensive per unit compared with automated lamination and alignment in large-scale runs.

6. Order Quantity

Like most custom electronic products, larger quantities significantly reduce unit pricing. Setup and tooling costs are spread across more units, and material usage becomes more efficient. Small pilot runs or prototyping batches have a higher cost per piece, especially if they involve manual assembly or frequent design changes. For reference, price per piece for small runs (50–100 units) may be two to three times higher than for bulk production (1000+ units).

7. Testing and Quality Requirements

Comprehensive electrical, mechanical, and environmental testing ensures product reliability but adds cost. High-end projects may require 100% functional testing, lifespan simulation, or environmental certification such as IP65 or UL compliance. While these steps increase production time, they guarantee stable long-term performance, especially in medical and industrial applications.

8. Packaging and Logistics

Proper packaging for delicate FPC assemblies prevents damage during transit. Anti-static bags, foam inserts, and moisture barrier films slightly raise packaging costs but are essential for protecting flexible circuits. International air or express shipping also affects total project cost, depending on order volume and destination.

9. Typical Price Range (for reference)

| Type | Description | Approximate Price (per piece, bulk order) |

| Simple FPC membrane switch | Single circuit, no LED, standard overlay | USD 2.00 – 5.00 |

| Mid-range version | With tactile domes and LED indicators | USD 5.00 – 10.00 |

| Complex design | Multi-layer circuit or backlighting integration | USD 10.00 – 20.00+ |

(Prices vary by circuit complexity, material choice, and order quantity.)

10. Tips for Cost Optimization

- Simplify circuit layout and avoid unnecessary vias or crossovers.

- Use standard connector types instead of fully custom connectors.

- Choose polyester overlay unless high impact or temperature resistance is required.

- Combine multiple switch functions into one flexible circuit to reduce tooling.

- Place orders in larger batches after prototype approval to lower per-unit cost.

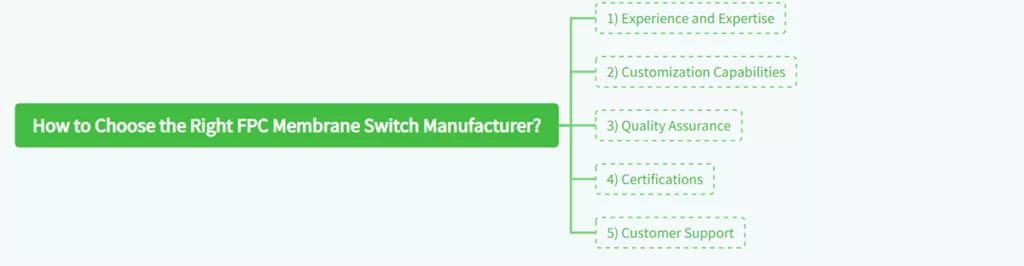

11. How to Choose the Right FPC Membrane Switch Manufacturer?

Selecting the right FPC membrane switch manufacturer is a crucial step in ensuring the success of your project. The manufacturer’s experience, technical capabilities, and quality control directly affect the durability, performance, and consistency of your final product. A dependable partner not only produces high-quality components but also understands your design goals, budget limits, and timelines.

When evaluating potential suppliers, focus on companies that have proven experience, strong industry reputation, and a clear record of producing reliable FPC membrane switches for different industries. Working with an experienced and technically capable manufacturer ensures smooth communication, timely project delivery, and switches that meet your exact design and performance specifications.

Below are the key factors to consider when choosing the right partner for your project.

1) Experience and Expertise

Choose a manufacturer with extensive experience in producing FPC membrane switches for applications similar to yours. Review their portfolio and ask for sample projects or reference clients. A company that has worked with medical, industrial, or automotive products usually has a deeper understanding of technical requirements such as durability, EMI shielding, or temperature stability.

Experienced teams can also provide valuable design suggestions to optimize your product for both performance and cost.

2) Customization Capabilities

Every project has unique functional and aesthetic needs. Ensure that the manufacturer can fully customize the design according to your specifications, including circuit layout, connector type, materials, tactile feedback, and backlighting features.

A strong manufacturer will have in-house design and engineering teams capable of turning your concept or 2D drawings into a complete production-ready layout. Ask if they can handle small prototype batches as well as large-scale production, so you can develop and test your design before mass manufacturing.

3) Quality Assurance

Reliable manufacturers follow strict quality control standards at every stage of production. Confirm that the company conducts 100 percent electrical testing and environmental reliability tests such as humidity, temperature cycling, and lifespan testing. They should also maintain documented inspection procedures covering visual appearance, lamination accuracy, adhesion strength, and circuit conductivity.

4) Certifications

Ask the manufacturer to provide up-to-date certifications that demonstrate compliance with international standards. Typical certifications include ISO 9001 for quality management and RoHS for material safety.

Some manufacturers serving the medical, defense, or automotive industries may also hold specialized certificates or testing capabilities. These documents prove that the production process is consistent, traceable, and aligned with global quality expectations.

5) Customer Support

Excellent customer support is essential throughout the entire project, especially during design and prototyping. A responsive and knowledgeable team can help you make fast design adjustments, resolve technical issues, and meet delivery deadlines. Look for manufacturers that provide dedicated account managers, regular progress updates, and reliable after-sales service.

Strong communication not only saves time but also helps prevent costly errors during production.

6) Technical Capability and Equipment

A top-tier manufacturer invests in advanced equipment such as automated lamination lines, laser cutters, digital printing systems, and precision electrical testers. Modern production tools ensure better consistency, tighter tolerances, and faster turnaround times. You can request a factory tour or video inspection to verify that they own and operate the equipment needed to produce high-quality FPC circuits and overlays in-house.

7) Delivery and Flexibility

Reliable suppliers are able to balance lead time, customization, and production volume efficiently. Ask about their standard delivery time and how they manage urgent orders or design revisions. Factories with flexible scheduling and well-organized logistics systems are more likely to meet your project timelines without compromising quality.

8) Pricing Transparency

While cost is always important, it should not come at the expense of reliability. Look for a manufacturer that provides clear, itemized quotations explaining the cost of materials, tooling, assembly, and testing. Transparent pricing builds trust and helps you make informed decisions about design trade-offs.

12. FPC Membrane Switch FAQs

Below are some frequently asked questions on FPC Membrane Switches:

1) What is an FPC Membrane Switch?

FPC Membrane Switch is a tough, durable human-machine interface which functions by disconnecting electric circuits upon the user pressing keys.

2) What are the main components?

Top graphic overlay, adhesive layer, spacer layer, FPC layer, and bottom adhesive layer.

3) What are its advantages?

Lightweight, space-saving, durability, flexibility, and customizable

4) Where is it commonly used?

Consumer electronics, automotive, industrial controls, aerospace, and medical devices.

5) How is it designed?

Through requirements analysis, schematic design, material selection, prototype development, testing, and production transition.

6) What issues might arise and how to troubleshoot?

Adhesive failure, wear and tear, intermittent functionality, and non-responsive keys. These can be minimized with regular inspection and maintenance.

7) How to maintain it?

Regular cleaning, avoiding extreme conditions, periodic inspections, and encouraging gentle use.

8) How to choose the right manufacturer?

Look for experience, customization capabilities, strong quality assurance, relevant certifications, and good customer support.

13. Conclusion

FPC membrane switches are a cutting-edge and versatile technology highly adaptable to any kind of application. Having their components, advantages, common applications, designing, and maintenance is significant in a bid to enhance the utilization of these versatile interfaces. Choosing a reputable producer also assures your switches’ consistency and durability, providing a seamless user experience for your end products.

Leave A Comment