Considering using kiss cut labels for your new project? Perhaps you happen to be interested in knowing the unusual features that make these labels. If so, you’ve come to the ideal place. During the span of this article, our objective is to unveil the mechanics of custom kiss cut labels and present you with helpful information on tips to achieve maximum output when placing an order.

1. What are Kiss Cut Labels

Kiss cut labels are a customized labeling product that can be specified to suit your specific requirements. What is different about them is the special border around the customized-shaped part of the label, which creates a distinctive look.

When a kiss cut label is created, it is meticulously cut through the material layer alone, preserving the integrity of the paper backing. This results in a refined border outlining the label. In the design proof provided below, you will observe the delineation between the cutlines. The magenta line represents the border of your label, and the green line represents the outline of the peelable part of your kiss cuts.

2. Key Specifications & Technical Parameters

Before kiss cut label ordering, learning the main specifications that contribute to determining their accuracy, resistance, and application suitability is crucial. They help customers communicate well with suppliers and ensure that each batch meets the anticipated performance level.

1. Cutting Precision & Tolerance

Kiss cutting requires extreme accuracy to cut through only the top material layer without damaging the liner.

Cutting Depth Tolerance: ±0.05 mm

Registration Accuracy: ±0.2 mm

Minimum Line Width: 0.3 mm

This precision allows complex designs, barcodes, and logos to be produced cleanly on various materials.

2. Material Thickness & Layer Structure

General overall thickness of kiss cut labels ranges between 0.05–0.15 mm, depending on the material and adhesive type.

| Layer | Typical Range | Description |

| Face Stock | 50–100 µm | Paper, PP, PET, or vinyl film |

| Adhesive Layer | 20–40 µm | Permanent or removable glue |

| Liner / Backing | 60–90 µm | Silicone-coated release paper or PET film |

Thicker liners are recommended for automatic label dispensers to avoid curling or tearing.

3. Adhesive Strength & Environmental Resistance

- Adhesion (Peel Strength): 1.0–1.5 N/cm

- Temperature Resistance: -20°C to 120°C

- Humidity Resistance: ≤5% deformation after 72 h at 40°C / 90% RH

- UV Stability: No discoloration after 300 h exposure

These properties ensure consistent performance in industrial, retail, and logistics environments.

4. Surface Compatibility

Kiss cut labels adhere well to smooth and non-porous surfaces such as glass, plastic, metal, and coated paperboard.

Avoid rough, oily, or dusty substrates to maintain full adhesion.

5. Label Format & Application

- Available in sheets (A4, A5, or custom layout) or rolls for automatic labeling machines.

- Core sizes: 1″, 3″, or 4″ depending on application.

- Winding direction and spacing can be customized to match labeling equipment.

6. Compliance & Quality Standards

All materials can be produced in compliance with:

- ISO 9001 – Quality Management

- RoHS / REACH – Environmental Safety

- SGS Certification – Adhesive and print surface safety verification

3. What are the Optimum Sizes for Kiss Cut Labels?

In custom label operation, there is no standard size that covers all applications. The greatest advantage of having a custom setup is the ability to select a size of label that perfectly fits into the location it will be used. The ideal dimensions for your kiss cut labels are contingent upon two key factors:

- The expanse of the surface where the labels will be affixed.

- The extent of coverage you desire for your labels.

In case you do not possess a targeted area wherein you will have the ability to attach the labels, or you want to sell the same labels to a broader customer base, you may want to stick with the standard size ranges pre-cut for kiss cut labels.

The sizes usually range between 5 to 10 cm, which is easy to use for decorating laptops and phones with elegance and class.

4. Why Kiss Cut Labels are Popular?

The global popularity of kiss cut labels stems from their remarkable versatility and ease of adaptability. Kiss cut labels offer a ground for creativity, with the possibility of being printed on numerous types of materials, including white vinyl, clear backing, brown paper backing, foil metallic backing, holographic metallic spectrum, and PVC material.

Also, the scope for personalization is endless. Right from die-cutting the label with a square backing to a personalized design printed on the backing, opportunities are endless. Additional touches such as an upscale gold finish, textured recesses, or opulent silver/gold-based prints for hologram labels enhance the beauty and appeal of kiss cut labels even more.

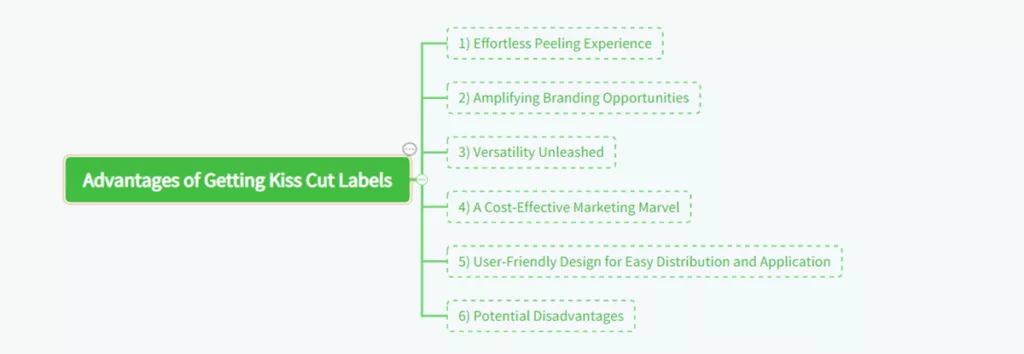

5. Advantages of Ordering Kiss Cut Labels

Enter the realm of kiss cut labels, and you’ll discover a treasure trove of benefits awaiting you. Come along with me to find out the advantages of these custom-cut labels.

1) Smooth Peeling Experience

The beauty of kiss cut labels lies in the ease of peeling. With the backing paper left in place, these labels come with an added border, which results in a silky peeling experience. Not only does this save precious time in applying, but it also enhances the overall customer experience when handing out or selling these lovely stickers.

2) Amplifying Branding Opportunities

Beyond functionality, the added border of kiss cut labels presents an opportunity for enhanced branding. Utilize this space wisely by incorporating a design to be printed onto the border. This strategic move allows for the inclusion of extra marketing messages while enabling consumers to peel off the labels and adorn their possessions solely with your captivating design. The best part? Printing on the border comes at no extra cost!

3) Versatility Unleashed

The characteristic that best describes kiss cut labels is their unparalleled versatility. Their peel-and-stick design makes them suitable for use on a diverse range of surfaces – from cars and product packaging to laptops and personal items. This versatility is a godsend for businesses seeking to increase brand visibility. The more surfaces your logo or branding appears on, the greater the exposure your business receives. Moreover, their ability to be shaped into different forms and patterns renders them ideal for a host of creative applications.

4) An Affordable Marketing Marvel

Among the characteristic advantages of kiss cut labels is the fact that they are inexpensive. Made in sheets rather than as a single unit, the labels offer an economical choice for businesses that are operating on a shoestring budget. Cheap as they are, they offer a significant promotional impact. With a number on each sheet, there are numerous opportunities to dazzle potential customers, making them an excellent inclusion in any advertising campaign.

5) User-Friendly Design for Easy Distribution and Application

The fully intact backing paper simplifies handling, distribution, and application. This aspect eliminates the possibility of tearing or damage, with the appearance and design of the label preserved. Moreover, their sheeted format simplifies distribution, be it at events or through mail, while the simplicity of peel-off functionality simplifies application for end users, boosting a positive experience with your brand. Additionally, we offer complimentary individual cutting for kiss cut labels!

Briefly, the flexibility, affordability, and ease of use of kiss cut labels render them a forceful tool capable of fortifying your marketing efforts, learning initiatives, or personal projects. Whether disseminating your business message or imbuing possessions with personal touches, these labels wait for the varied role.

6) Potential Disadvantages

While kiss cut labels are a great advantage, they are not without their own set of limitations. First, while the backing paper adds convenience, it can occupy more space than individual die-cut labels. They are also less robust than die-cut labels, cutting through the label material and backing paper to yield a freestanding piece.

6. Benefits of Kiss Cut Labels to Small Businesses

For small business entrepreneurs who are struggling to comprehend the intricate reality of small businesses, kiss cut labels are an assurance of hope, offering an array of advantages to be taken advantage of. Let us proceed into the arena of these custom labels and understand the benefits they have to offer to small business owners.

Kiss cut labels represent the ultimate in customizability that allows you to create each label to exactly serve your company’s unique branding and promotion requirements. This level of customization not only optimizes brand recognition but makes your marketing piece appear to contain high-end, exclusive, sophisticated elements.

In addition, these stickers offer an affordable way to promote your business as versatile tools that can be easily stuck onto packages, promotional items, or even daily items with ease. Their ease of integration into multiple touchpoints of your business ecosystem boosts brand visibility and makes a lasting impression on prospects and customers alike.

Also, the ease of distribution adds an extra layer of convenience to your marketing. Whether in a targeted campaign or a strategic branding initiative, kiss cut label distribution is an easy process, allowing you to extend the reach of your brand with ease and sophistication.

In essence, the benefits of kiss cut labels for small businesses extend far beyond mere looks. They are strategic marketing tools that build brand visibility, generate interest, and boost the overall return on investment of your marketing campaigns, and they are priceless tools in your business operations.

7. The Top Applications of Kiss Cut Labels

While the versatility of kiss cut labels offers endless possibilities for creativity, there are two exceptional applications that best illustrate the unique advantage of these personalized stickers.

1) Sophisticated Designs

Amidst the argument for the significance of the backing paper, it is not feasible to overlook its groundbreaking influence on label design. Where complex designs with thin cutlines and intricate edges are likely to be folded or torn, kiss cut labels step in as the hero, providing the precise amount of protection needed for the preservation of the integrity of your labels.

Moreover, the additional sticker paper not just safeguards the design but also adds to the joy of peeling by offering a smooth and hitch-free application process. This quality of attention heightens the total visual appeal of the labels and makes them an enjoyable addition to any promotion or branding campaign.

2) Interactive Giveaways

Personalized kiss cut labels, which are made specifically for you, are the perfect branded giveaway, offering a blank canvas on which you can imprint your company logo, motivational slogans, or motivational artwork. Through distributing these personalized labels, you not only offer a symbol of appreciation, but you also make a physical connection with your readers.

The popularity of kiss cut stickers giveaways is in deliberately placing branding on the edge so that customers can adorn their goods with a touch of sophistication. This stealth branding strategy convinces customers to showcase your stickers on their machines proudly, making the brand more visible and creating a sense of belongingness and loyalty.

Effectively, the use of kiss cut labels on intricate designs and interactive promotions is more than the usual marketing practices, an elegant and efficient way of captivating your audience and elevating your business to greater heights in the competitive marketplace.

8. Kiss Cut Label Material & Adhesive Selection Guide

Choosing the best label material and adhesive pairing is vital in order to preserve print quality as well as long-term adhesion. The selection depends on your product’s surface type, application, and environmental use.

1) Common Face Stock Materials

| Material Type | Key Features | Typical Applications |

| Paper | Economical, smooth printing surface, easy to cut. | General product labels, indoor use, food packaging, price tags. |

| PP (Polypropylene) | Waterproof, oil-resistant, flexible; excellent for curved surfaces. | Beverage bottles, cosmetics, healthcare products. |

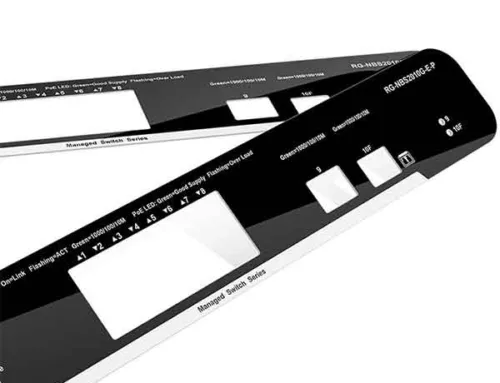

| PET (Polyester) | High durability, heat and chemical resistance; dimensional stability. | Electronics, industrial, automotive labeling. |

| Vinyl (PVC) | Strong adhesion and outdoor resistance; supports intricate shapes. | Outdoor branding, warning stickers, durable signage. |

| Specialty Films | Metallic, clear, matte, or textured options for premium visual effects. |

Luxury branding, electronics, and packaging labels. |

Tip: Paper is appropriate for inexpensive or short-term projects, while PP, PET, and Vinyl are appropriate for industrial or long-term use.

2) Adhesive Types & Their Characteristics

| Adhesive Type | Performance | Ideal Conditions / Surfaces |

| Permanent | Strong, long-term adhesion; resists peeling and moisture. | Smooth plastics, coated paperboard, metal surfaces. |

| Removable | Allows clean removal without residue; lower tack strength. | Temporary promotions, glass, or reusable packaging. |

| Freezer / Low-Temperature | Maintains adhesion in cold or frozen environments. | Frozen food packaging, refrigerated storage labels. |

| High-Temperature / Industrial | Resists heat, chemicals, and UV exposure. | Automotive, electronic, and machinery labeling. |

| Ultra-Clear / Transparent | Designed for no-label look with clear films. | Cosmetic packaging, bottles, and transparent surfaces. |

Suggestion: Always test the adhesive on your surface of choice to confirm performance, especially for textured, coated, or flexible surfaces.

3) Environmental & Application Considerations

When selecting materials and adhesives for your kiss cut labels, think about where and how they will actually be used. Conditions surrounding it have a huge effect on the long-term performance of a label. Labels used in cold storage or on packaging frozen foods, for example, need an adhesive that stays tacky in sub-zero temperatures. Conversely, applications for high-temperature environments like on machinery or electronics need adhesives that will not peel or soften when exposed to heat.

Moisture, UV light, and chemicals may also affect label life. If your product is exposed to a wet or outdoor condition, research water-resistant films such as PP or PET with UV-resistant coating. For chemical uses, like cleaning supplies or auto fluids, a solvent-resistant adhesive is your best option.

Surface texture matters, too. Smooth materials like glass, metal, or coated plastic generally work with most adhesives, while textured or curved surfaces might need stronger or more flexible options to stay flat and secure. Finally, think about how you’ll apply the labels. If your production line uses an automatic labeling machine, choose a material and liner combination that feeds smoothly without curling or tearing.

By considering these factors in advance, you can avoid common issues like peeling, bubbling, or fading, and make your kiss cut labels look just as pretty months after application as they did on day one.

9. Production Process & Quality Control of Kiss Cut Labels

Every kiss cut label is manufactured by a methodically controlled process so that every piece will be clean in appearance, a perfect fit, and work well when applied. The process may look easy from the outside, but accuracy and consistency are what distinguish good from great.

It all starts with prepping the materials. The face stock and adhesive liner chosen are laminated into a solid, level base to print on. Then, the design is printed—digitally for short runs or flexographically for large-volume orders. During printing, color density, register, and clarity are closely monitored to ensure each batch meets approved artwork.

This is followed by the most important process: kiss cutting. In this, high-end cutting machines slice through the top surface of the material carefully without even touching the backing liner. The cutting depth is regulated to a fraction of a millimeter so that the labels can be removed cleanly and the sheet doesn’t lose its integrity. For detailed graphics or small text, laser or rotary die-cutting systems are used for finer accuracy.

After cutting, every batch goes through a quality inspection. Operators check for consistent cut depth, clean edges, accurate alignment, and smooth peeling. Random samples are also tested for adhesion strength and color stability. Some customers request extra QC checks like barcode readability or liner compatibility for automatic labeling machines, and those are all verified before packing.

Last but not least, the labels are packaged and documented. Every order is labeled with its production batch, material code, and inspection status to guarantee complete traceability. Prior to shipping, our staff conducts a final inspection to ensure the sheets or rolls are flat and ready for use.

In short, behind every set of kiss cut labels is a mix of high-precision equipment, trained technicians, and a strict quality control routine. That’s what guarantees your labels arrive clean, consistent, and production-ready, no surprises, just reliability.

10. Kiss Cut Label Cost Factors & Pricing Guide

The cost of kiss cut labels depends on several key factors. By understanding what drives pricing, you can better plan your order and make smarter sourcing decisions.

1. Material choice matters most

Paper is the least expensive option for short-term, in-house, or throwaway labels. Synthetic materials like PP, PET, or vinyl are more expensive but offer greater durability, flexibility, and resistance to water, oil, and abrasion. Specialty finishes like metallic film, matte coating, or clear labels, offer extra visual appeal but increase production expense.

2. Printing method and design complexity affect setup costs

Digital printing is appropriate for low runs and multiple designs because it is not plate-based. Flexographic printing is more appropriate for large runs. More complex designs with thin lines, gradients, or specialty inks (e.g., metallic or spot UV) require additional setup and calibration time.

3. Order quantity drives unit price

Longer runs essentially bring the cost per label down because setup and cutting costs are divided among a greater quantity of units. Small orders are great for testing or limited runs but, of course, more costly per unit. If your design is fixed, buying in bulk is always cheapest.

4. Label size and shape influence cutting efficiency

Geometries as simple as rectangles and circles are quicker and less costly to produce. Irregular or complex shapes require special dies or the precision of laser cutting, which requires both setup time and higher labor cost. Similarly, packaging format, either sheets, rolls, or pieces, determines speed and expense of production.

5. Logistics, compliance, and documentation add value and cost

Shipping distance, protection from packaging, and required certifications (RoHS, REACH, or SGS) contribute negligibly to the overall price. For export orders, proper labeling and traceability documents ensure smooth customs clearance along with quality consistency.

Tip: Always specify your material, finish, size, quantity, type of adhesive, and packaging format when asking for a quote. Clear information helps suppliers to calculate proper prices and minimizes communication time.

In summary, the key to cost-effectiveness is finding the balance between volume and quality. With the right supplier, you can choose materials and processes to meet your project goals, whether you’re shooting for upscale presentation or budget-conscious performance.

11. How to Find a Reliable Kiss Cut Label Manufacturer?

Finding the right manufacturer is as important as finding the right materials. The right partner will not only ensure you consistent quality but also time savings, reduced waste, and easy scalability of production. The following are the key factors to evaluate when selecting a kiss cut label manufacturer.

1. Check manufacturing experience and specialization.

Start by looking for a label maker that specializes in label manufacturing, not generalized printing. A company with a long history of kiss cutting and die cutting will know about depth control, liner compatibility, and print registration, all affecting label performance. Ask for samples of past work or case studies from your sector.

2. Evaluate material and process capabilities.

The good manufacturers should be able to offer sufficient face stock materials such as paper, PP, PET, and vinyl, together with different types of adhesives to suit different environments. They must also be able to offer flexible printing capacities such as digital for smaller orders and flexo for bulk orders, as well as be in a position to process additional finishes such as lamination, UV coating, or metallic effects.

The more material and process variety they possess, the more they can tailor solutions to your needs.

3. Review quality control systems and certifications.

A reliable supplier always has a well-organized QC process. Seek out certifications such as ISO 9001, RoHS, or REACH, which are marks of continuous quality and material safety. Ask what they test adhesion for, color uniformity, and cut depth. Reliable manufacturers can generally provide inspection reports or sample verification photos prior to shipping.

4. Request samples and evaluate accuracy.

Before agreeing on a bulk purchase, request pre-production samples or proof sheets. Check the cut accuracy, adhesive quality, and color registration against your artwork. A supplier who freely provides samples and openly discusses improvements is far more reliable than one that avoids quality checks.

5. Assess communication and responsiveness.

Effective and timely communication is crucial for efficient cooperation. Good suppliers are timely, aware of your technical requirements, and make proactive suggestions when required. Long or uncertain responses generally point to poor in-house coordination, leading to production lag.

6. Consider production lead time and flexibility.

A reliable manufacturer should provide sincere production schedules and update you during the process. For repeat order production or production under tight deadlines, production flexibility is equally important. Ask if they can accommodate rush orders, partial shipping, or rolling production schedules for ongoing supply.

7. Compare overall value, not just price.

Lowest cost is not always best value. Balance the total reliability: quality, lead time, packaging, after-sales service, and consistency. A modest premium from an experienced vendor may save you a costly reprint or product recall later on.

Tip: Select a partner that is respectful of your project as a long-term relationship, not a quick deal. The leading manufacturers are technical consultants, helping you achieve the best material selection, print design, and packaging optimization for best quality and cost trade-offs.

12. Kiss Cut Labels Common Issues & Troubleshooting

Even when using quality materials and precise cutting, kiss cut labels can sometimes experience small issues in processing or adhesion. Awareness of these common issues and how to resolve them will avoid delays and unnecessary use of materials.

1. Edge lifting or peeling

If the edges of labels start to curl once applied, it normally means the surface wasn’t completely smooth or clean. Always wipe off oil, dust, and moisture before applying the label. When using textured or curved surfaces, apply a more aggressive or flexible adhesive to form a strong bond.

2. Misaligned cuts or off-center designs

When cut lines are not quite matching printed design, the issue is generally due to misregistration in cutting or printing. Calibrate cutter on a regular basis and align properly before cutting large batches. Uneven liner thickness will also cause slight shifts, so check material consistency too.

3. Bubbles or trapped air

Air bubbles may result from manual application. To prevent it, use even pressure using a scraper or roller from the center to the outside. When manually applying labels, go slowly and do not stretch the material. If using automatic application, use proper tension and speed of feeding on the machine.

4. Weak adhesion or falling off

If a label does not stick well, the adhesive type might not be appropriate for the surface material or temperature conditions. Test the adhesive on your substrate before production. For cold, oily, or rough surfaces, use a high-tack or specialty adhesive for those conditions.

5. Cracked or torn labels during peeling

This problem occurs often when the kiss cut depth has been placed too deep, slightly nicking the liner. Reduce the cutting pressure to only cut face stock. Using a thicker liner or changing to a sharp blade may also aid in better peeling action.

6. Smudged or faded print

Fading or smudging generally indicates inadequate curing of the ink or incorrect coating of the material. Use UV-cured inks on non-porous films like PET and PP, and use the right drying temperature. For outdoor applications, add lamination or UV coating to extend print life.

By intercepting these issues early on and pre-testing products before mass production, you can greatly reduce waste and have consistent, professional output. Well-organized suppliers will also aid in root-cause analysis and offer backup materials or adhesives as needed, saving time and money in the long run.

13. Does the Size of a Kiss Cut Label Incorporate the Entire Label or Only the Peelable Label?

When entering the realm of kiss cut labels, a natural question arises regarding the size specifications of these intricate stickers. As a kiss cut label is made up of two distinct components – the border and the peel-off portion – the question arises: What size should be used when ordering such custom stickers?

It is interesting to note that the size you order includes the two components of the label: the peelable component and the border surrounding it. This implies, for instance, that when you order a 5x5cm kiss cut label, the size you order should include the entire label, i.e., the peelable label and the border that surrounds it. The actual peelable sticker itself will be a little smaller than the ordered size of 5x5cm, considering that there is a border surrounding it.

But the glory of kiss cut labels is the liberty it gives regarding customization. You are free to decide how big or small the border of the peelable sticker should be, giving you a sense of personalized and customized feel to your label.

After your selection of the desired kiss cut stickers, you can decide to add special requirements for our expert design team by opting for “add proofing instructions.” This feature enables you to convey any special requirement or details regarding the size, structure, or composition of your labels such that the final result ensures your idea in harmony.

Effectively, having knowledge of kiss cut label sizes places you in the driver’s seat to make intelligent choices while ordering these functional stickers so that you can select a product consciously that is not just visually appealing but also one that is ideally suited to your requirement, representing your brand in its best and most sophisticated light.

14. Conclusion

Put briefly, kiss cut labels represent the ultimate in flexibility and unlimited customization, attracting visionaries, creatives, and entrepreneurs alike. Commended for their flexibility and easy customization, the labels have become the preferred option for individuals with refined tastes who want to make a statement with a dash of elegance.

The inherent cost-savings and level of customization make kiss cut labels a strategic value in the realm of branding, a cost-saving and hassle-free way of projecting your business persona with panache. Utilizing the potential of kiss cut labels not only raises the visibility of your brand but also creates channels for ease of promotion and engagement with your target audience.

So why not make the leap and unlock the revolutionary power of kiss cut labels and elevate your company’s standing in the dynamic market situation to a new height? Harness the beauty and functionality of these bespoke labels to weave a compelling tale for your business that makes a lasting impression on clients and positions your company a notch above the sea of competition.

Leave A Comment