Custom Membrane Switches from MSTR

MSTR has been the top membrane switch manufacturer in China since 2005, providing quality solutions for medical, industrial, and consumer electronics applications. At our 5,000 sqm factory with advanced production capabilities we manufacture up to two million membrane switches each month while upholding efficiency and quality in production processes.

Our membrane switches are constructed from durable polyester (PET) or polycarbonate (PC), with switch contacts either printed or chemically etched to maximize performance. Ideal for electronic control panels, keypads, and interface systems alike, our pressure-sensitive membrane switches activate functions through pressure-sensitive actuation to guarantee seamless operation, compact design,n and resistance against moisture, dust, and contaminants.

At MSTR, we specialize in fully customized membrane switches to meet specific client requirements. From tactile to non-tactile interfaces and backlit designs to EMI-shielded solutions, our switches provide high reliability, intuitive operation, and long-term durability – essential features in modern electronic devices and industrial applications alike.

Featured Membrane Switches

Waterproof Membrane Switch

MSTR’s waterproof membrane switches are specifically engineered for harsh environments with high humidity levels, exceeding IP67 ratings. Their fully sealed structure offers IP69 protection to provide greater resistance against moisture intrusion, dust particles, and high-pressure washdown.

Our switches still operating in a regular manner even when wetted through, these switches achieve this through the use of high-bond adhesives, specialty coatings, and careful sealing processes. Suitable for medical, industrial, marine, and outdoor uses; they provide durability, reliability, and silky smooth operation even in extreme conditions.

Tactile Membrane Switch

MSTR’s tactile membrane switches deliver stable circuit activation with positive touch, and it is therefore ideally suited for use in control panels, keypads and interface systems. Their tactile domes deliver crisp tactile responses for accurate operation in industrial, medical and electronic applications.

MSTR tactile membrane switches are engineered for durability and precision, offering customizable actuation force, embossing, and backlighting options to meet any your need. From simple controls to complex multi-layer keypads, we provide high performance solutions designed to meet any challenge with unparalleled results.

FPC Membrane Switch

MSTR’s FPC membrane switches use flexible printed circuit boards (FPC) to produce lightweight, ultra-thin switch interfaces that are ultra durable. Compared with traditional membrane switches, our FPC designs provide greater flexibility, higher circuit density and improved reliability – ideal for compact yet high performance electronic applications.

FPC membrane switches are highly sought after products for consumer electronics, medical devices, automotive interfaces, drones and industrial controls due to their superior bendability, environmental resistance and long lifespan. Though more costly than standard designs, FPC switches deliver exceptional precision, space efficiency and advanced connectivity features needed in demanding applications.

Steps to Custom Membrane Switches

Requirement Analysis & Design

Once receive your requirements, MSTR will carefully consider client’s needs to create membrane switches with custom circuitry, tactile feedback, and durability for an enhanced user experience.

Material Selection & Layer Construction

We use PET, PC, and 3M adhesives for their layer construction projects, offering waterproofing, dust resistant, and backlighting features for increased durability and performance.

Circuit Design & Printing

MSTR offers custom circuit design and printing in silver or copper to provide conductivity and support LEDs, EMI shielding, multi-layered custom designs, LEDs with embedded driver chips and multi-layered custom designs.

Adhesive Layering & Die-Cutting

MSTR provides adhesive layering and die-cutting services, laminating membrane layers with pressure-sensitive adhesives before carefully die-cutting them to meet exact client specifications and designs.

Function Testing & Quality Inspection

MSTR provides rigorous electrical, tactile and environmental tests on each membrane switch in its inventory to ensure it satisfies 100% quality and performance standards.

Final Assembly & Secure Delivery

Final Assembly and Secure Delivery MSTR delivers finalized connectors in protective packaging and ships worldwide with full installation guidance and technical support for easy delivery.

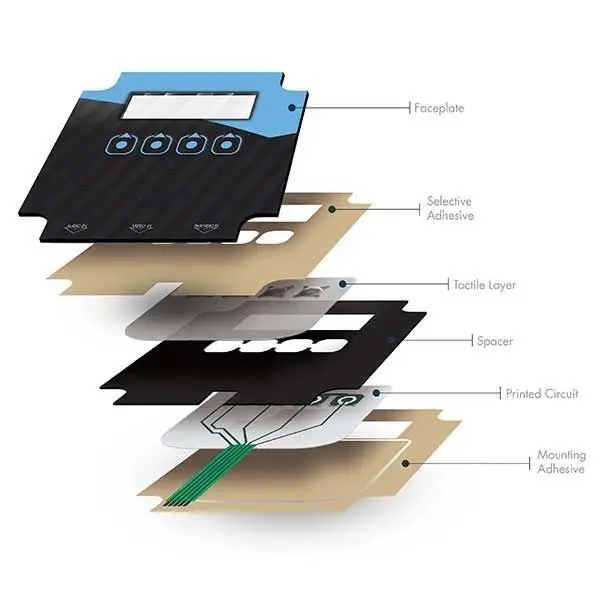

Custom Membrane Switch Structure and Materials

MSTR can customize membrane switches with various structural enhancements and material options to meet your specific application needs. Our designs can incorporate metal domes for tactile feedback, shielding layers for anti-static and interference protection, and waterproof and dustproof design to meet IP-rated requirements.

We offer panel materials such as PET for durability, PC for superior visual clarity, and specialized materials for unique demands. The circuit options are silver paste circuits, FPC, and PCB for optimal performance and reliability. All our membrane switches are completely customised to your design for high quality and reliability.

Custom Membrane Switch Key Design and Appearance

MSTR can customize membrane switch key designs to enhance user experience and functionality. We offer flat keys, embossed keys for a three-dimensional feel, and metal domes for precise tactile feedback. Our printing options include PANTONE color matching, screen printing for long-lasting vibrancy, and digital printing for high-detail graphics.

For improved readability, even in low ambient light levels, we provide a range of backlighting possibilities including LED, EL, and light guide film (LGF) technology. Each design is custom-specific to your application for optimum class performance, aesthetics, and long-term reliability.

Custom Membrane Switch Electrical Performance and Connectivity

MSTR can customize membrane switches with specialized electrical performance and connection versatility to fit your device application. Our designs support customized working voltage, current, contact resistance, and insulation resistance to ensure stable and reliable operation. We offer various connection methods, including FPC, ZIF, terminals, and direct soldering, to fit different integration needs.

Also, tailor-made tail cable lengths for convenient connection with your equipment are available. Each membrane switch is built to deliver optimum electrical performance and durability, adhering to the industry’s best.

Custom Membrane Switch Additional Features and Application Scenarios

MSTR can customize membrane switches with value-added functionalities to meet the requirements of various industries, including outdoor, industrial, medical, and food equipment applications. Our designs can be infused with waterproof and dustproof protection with IP-rated sealing, as well as high-temperature resistance for demanding environments.

We offer integration with premium features such as touchscreens, RFID/NFC technology, and EMI/ESD shielding for anti-interference capability. Our membrane switches have long life with durable construction, which can withstand 500,000 to over 1,000,000 keypress cycles. Each solution is totally customized to offer high reliability, functionality, and durability for rugged applications.