With individualization and branding being the driving forces in our world today, metal transfer stickers have emerged as a new and unique vehicle. Whether personal style or advertising one’s business, metal transfer stickers offer an uncommon way of adding a touch of sophistication to everyday objects or creating long-lasting marketing materials to remember.

So, what exactly are metal transfer stickers? How do they distinguish themselves from conventional stickers? Why have they garnered favor among individuals and businesses alike? The answers lie within this article. First, join us as we uncover the magic behind “What are metal transfer stickers?”!

1. What are Metal Transfer Stickers?

Metal transfer stickers, those lovely pieces of art created from a thin strip of metallic material, possess this remarkable property of adhering to all types of surfaces with ease and grace. These stickers are the epitome of class and sophistication, and they elevate your products and promotional items to a greater level of refinement.

With their mirror sheen and long-lasting adhesive, metal transfer stickers are a dazzling beacon of difference, setting your brand apart and making an indelible impression on your customers. Whether adding the upscale touch to your packaging with metallic accents or creating eye-catching promotional items, the stickers offer a sophisticated and budget-friendly solution to your branding needs.

2. What is the Structure & Material Composition of Metal Transfer Stickers?

On the basis of a close familiarity with the inner reality of metal transfer stickers, I can go ahead and examine their internal make-up.

A common internal make-up of transferable stickers is generally three-layered: a backing paper, a vinyl decal, and a transfer film or tape.

- Backing paper: The backing paper, or substrate, is the lower portion of the sticker. Sometimes coated paper or a transparent film, this component of the sticker is the protective layer that shields the adhesive backing from drying out until it’s applied.

- Vinyl decal: Between the transfer tape and the backing paper lies the vinyl decal, the creative hub of the sticker. Constructed of quality-grade vinyl material, this is the layer where detailed designs and engaging text spring to life in an array of colors.

- Transfer tape: At the top of the structure lies the transfer tape, a transparent, clear sheath usually constructed of clear plastic. The outermost layer gently grasps the vinyl decal, offering an even, silky transfer on the intended surface with grace and finesse.

3. How do Metal Transfer Stickers work?

Custom transfer stickers operate by an innovative three-layer design, and usage entails the following process:

- Remove the backing paper.

- Apply the sticker to the intended clean, dry surface.

- Gently remove the transfer tape, leaving the vinyl decal adhered to the surface.

4. Key Specifications & Technical Parameters of Metal Transfer Stickers

It is helpful to be familiar with the important technical specifications of metal transfer stickers prior to ordering. Those specifications dictate performance, durability, and compatibility with surfaces.

| Specification | Typical Range | Purpose |

| Total Thickness | 0.05–0.15 mm | Defines flexibility and strength |

| Metal Layer | 10–25 µm | Controls gloss and durability |

| Adhesive Layer | 20–40 µm | Affects adhesion to textured surfaces |

| Peel Strength | ≥1.5 N/cm | Adhesion performance |

| Temperature Resistance | -20°C to 120°C | Indoor & outdoor use |

| UV / Humidity Resistance | Stable up to 300 h | Prevents fading or peeling |

| Size Tolerance | ±0.1 mm |

Dimensional consistency |

Surface Compatibility: Applicable to metal, glass, ABS, PC, PET, and painted surfaces. Avoid dusty, oily, or rough textures for best results.

Available Finishes: Mirror chrome, brushed metal, matte metallic, or custom dual-color effects. Pantone color matching available for OEM branding.

Compliance: All materials can comply with ISO 9001, RoHS, and REACH standards.

5. Features of Metal Transfer Stickers

After learning “How do metal transfer stickers work”, we will show you 5 key characteristics features that make them special:

1) Detail Accuracy

The defining characteristic of custom metal transfer stickers is that they have immense accuracy in depicting detailed designs. From subtle lines to small details and tiny typography, the stickers are adept at replicating even the finest details from the original painting.

This precision renders them the perfect choice for showing detailed artwork or creating visually appealing graphics, such as business logos, name tags in elegant handwritten fonts, product labels, etc.

2) Professional Appearance

Metal transfer stickers possess a sophisticated and professional appearance that sets them apart.

Distinct from standard stickers by their lack of background, transfer stickers print onto surfaces without background image, revealing the look of a design having been stamped or painted onto the base itself.

Furthermore, stickers can be given a specialty 3D finish, adding an element of visual sophistication and an upscale, professional appearance.

3) Durability

Made of heavy-duty, weather-proof vinyl material, transfer stickers are extremely durable, withstanding the mistreatment of regular handling.

Resistance to peeling, cracking, and fading, the stickers maintain their as-new appearance over a period of years and continue to be a favorite for long-term usage.

Attached on any of the above-mentioned surfaces – cars, laptops, walls, or windows – personalized transfer stickers prove resistance to diversified environmental situations, sunlight, and random cleaning.

4) Customization

Metal transfer stickers allow for extensive customization options, enabling consumers to bring their personalized concepts to life quickly and with ease.

They may choose any shape, size, and color combination, with the stickers being precisely cut to any desired shape for unique outlines and contours. The ability to create unique designs through this allows logo-shaped transfer stickers or themed icons to be designed.

Additionally, the object and layout position of things in the design can be manipulated to develop an entirely new item, and each application is singly customized.

5) Variety of Uses

Complimented as versatile, transfer stickers are applied onto a broad spectrum of surfaces, from glass and plastic to metal and painted walls.

Applied to personalizing laptops, water bottles, and phone coverings, and to branding cars, shop windows, and promotion products, the versatility of metal transfer stickers makes them an indispensable tool for personal, business, marketing, and event activities.

6. Disadvantages of Metal Transfer Stickers

Educating yourself on the characteristics of metal transfer stickers, you can deduce that they possess several benefits. While custom transfer stickers also possess several benefits, it is essential to note some potential drawbacks that may be involved with the utilization of them.

1) Require Application Skill

The application of metal transfer stickers requires a certain level of finesse because it involves peeling off layers cautiously that may present potential challenges:

- When peeling away the backing layer, there is a possibility of inadvertently pulling away minute, fragile details as well.

- Once the sticker is placed onto the target surface and the transfer tape is pulled off, there is a risk that portions of the vinyl sticker itself will also be pulled away with the tape. While not as probable as the first procedure, this too is something to be on guard for, particularly with extremely fine detail.

In order to minimize such risks, one should be advised to rub and press the sticker lightly before peeling away any layer in order to peel away and should practice the applying process several times to achieve maximum performance.

2) One-Time Use

Custom transfer stickers are typically intended for a single use. While they may be removed from surfaces, it is harder than in the case of regular stickers. Sadly, once a transfer sticker has been used, attempts to move it around may result in sticker damage, rendering it unusable again.

3) Potential Surface Damage

Removal of transfer stickers can also result in both sticker and surface damage. The stickers will likely deposit residue or adhesive marks depending on adhesive properties of the stickers and the nature of the surface to which they had been adhered. The removal of such residual marks may be corrected through wiping with a damp cloth.

In certain situations, aggressive removal can lead to scratching or marring of the material below.

Despite these drawbacks, custom transfer stickers are superior to other choices when it comes to durability, professional look, and print quality.

When weighing putting up transfer stickers, their long-term effects have to be taken into consideration. To a person unaware of how they are applied, it is reasonable to try attaching a single sticker or two as an experiment prior to formally putting them up.

By being careful with application and understanding the adhesive nature involved, tremendous results can be achieved. Transfer stickers, for instance, may be utilized optimally in branding, labeling, and as thoughtful gifts.

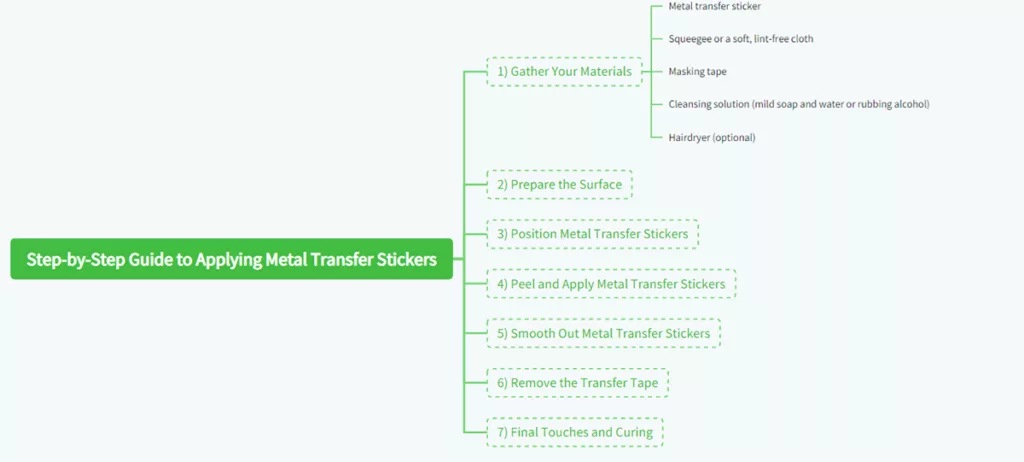

7. Step-by-Step Procedure on Applying Metal Transfer Stickers

The process that follows shall guide you on accurate steps and how-to’s on having your metal stickers placed to perfection.

1) Gather Your Materials

Before you begin the process of application, ensure that all tools required are within your reach:

- Metal transfer sticker

- Squeegee or a soft, lint-free cloth

- Masking tape

- Cleansing solution (mild soap and water or rubbing alcohol)

- Hairdryer (optional)

2) Prepare the Surface

Finish the cleaning of the surface intended to be painted in order to remove all traces of dust, grease, or residue. Employ a weak detergent or water with rubbing alcohol solution. It is important to allow the surface to dry completely before proceeding to the next step.

3) Position Metal Transfer Stickers

Utilize the masking tape in masking the sticker’s position on the target spot without peeling off the backing paper. This strategic approach helps you make corrections until it becomes flawless.

4) Peel and Apply Metal Transfer Stickers

With gentle care, peel the backing paper from one corner of the sticker. Doing so, handle the adhesive side with utmost care to keep it away from external contact. In the event of big stickers, use the wet method by spraying the adhesive side gently using a water and soap mixture. The process provides room for adjustment and facilitates air bubble removal.

5) Smooth Out Metal Transfer Stickers

Smooth out the sticker with a squeegee or with a soft cloth, beginning in the center and moving out towards the edge. This will get rid of any air bubbles that could be trapped and provide good adhesion.

6) Remove the Transfer Tape

If your sticker incorporates a transfer tape, execute its removal in a gradual manner and at a sharp angle. This precautionary measure prevents the inadvertent lifting of the sticker along with the tape.

7) Final Touches and Curing

Press lightly along the edges of the sticker to ensure total adhesion. Let the sticker cure and dry for a minimum of 24 hours before subjecting it to extreme environments or cleaning processes.

8. Industrial & Commercial Applications of Metal Transfer Stickers

Metal transfer stickers achieve world-wide use in commercial labeling and industrial product identification because of their metallic sheen, detailed textures, and industrial durability. Below are the major industries and applications in which they offer form and function benefits.

1. Electronics & Consumer Devices

Metal transfer stickers are commonly used to enhance the visual identity of electronic products.

- Applications: Laptop logos, speaker badges, headphone covers, charger covers.

- Benefits: Good metallic appearance, sharp logo definition, heat- and solvent-resistant.

Optimally used by OEM electronics companies to achieve a thin, durable metal finish without product weight increase.

2. Home Appliances & Smart Devices

Metal transfer stickers are often used on control panels, logos, and trim decoration by home appliance companies.

- Applications: Refrigerators, air purifiers, washers, and smart control panels.

- Benefits: Scratch-resistant, good adhesion to plastic and coated metal, works well on curved surfaces.

Ideal for glossy or matte product surface finishes.

3. Automotive & Transportation

In automotive markets, these stickers serve as light-weight metal nameplate substitutes.

- Uses: Dash emblems, gear knobs, steering wheel logos, motorcycle trim.

- Benefits: Temperature, vibration, and bonding without defect on ABS or aluminum parts.

Utilized by automobile accessory manufacturers for labeling and branding in hostile environments.

4. Packaging & Branding

Metal transfer stickers bring product packaging a little luxury, embossed metal appearance — one popular with cosmetics, spirits, and luxury gift boxes.

- Applications: Perfume packaging, skincare containers, wine labels, jewelry packaging.

- Benefits: Sophistication on visual side, finish can be customized (gold, silver, rose gold), great surface hold.

Increases product and brand perception.

5. Furniture, Decor & Lifestyle Products

Home decor and furniture companies use metallic transfers to show brand marks in a more sophisticated way.

- Applications: Lights, mirrors, wooden frames, metal furniture, decorative panels.

- Advantages: Resistant to wear and tear, resistant to humidity, and can be used in conjunction with wood finishes and varnishes.

6. Industrial Equipment & Machinery

When applied in industry, metal transfer stickers act as working nameplates and product identification.

- Applications: Control panels of equipment, industrial machinery, and precision equipment labels.

- Advantages: Chemical resistant, long-lasting, and suitable in heat- or oil-exposed conditions.

Provides sharp branding and serial identification with minimal maintenance.

7. Fashion Accessories & Custom Merchandise

Metal transfer logos are also used for small-batch, customized branding.

- Applications: Eyewear, watches, mobile accessories, promotional items.

- Benefits: High-end metallic embellishment for small items, giving a luxurious touch feel.

Suitable for OEM and ODM customers producing luxury or design products.

Tip for Buyers:

When describing your use to a supplier, say:

- Surface type (metal, glass, plastic, coating)

- Environmental exposure (indoor, outdoor, high-temp)

- Desired finish (mirror, brushed, matte)

This ensures optimal material correspondence and adhesive performance for your specific line of products.

9. Common Issues and Solutions of Metal Transfer Stickers

Encountering obstacles is a natural part of the journey when working with metal transfer stickers. Below are some prevalent issues and their corresponding solutions:

1) Inadequate Adhesion of Metal Transfer Stickers

If the sticker won’t adhere, make the surface perfectly clean and totally dry. Apply hard pressure using a squeegee, thereby enhancing adhesion.

2) Battle Against Air Bubbles

To combat air bubble formation, continue with the process patiently, being methodical in your action. Utilize a squeegee to ever so lightly press the sticker flat while gradually making your way through. To address stubborn bubbles, gently peel and reapply the sticker.

3) Pesky Lifting Edges

In the event that the edges of the sticker are peeled up, push down firmly to secure them and allow the sticker to cure longer. Application of a hairdryer at slow speed can help enhance adhesion.

10. Performance Testing & Quality Control of Metal Transfer Stickers

At the factory production facilities, all batches of metal transfer stickers undergo strict inspection and reliability tests for ongoing performance and quality. The tests ensure adhesive strength, durability, and visual correctness required for branding and industrial applications.

1. Incoming Material Inspection

All materials, including metallic films, adhesives, and transfer liners, are examined for surface consistency, thickness, and chemical compliance.

Only RoHS- and REACH-compliant materials are used to guarantee conformity to global environmental regulations.

2. Printing & Coating Quality Check

Metallic coatings and print layers are monitored during production for gloss uniformity, color conformity, and consistent edge definition.

Equipment used: Spectrophotometer, colorimeter, and magnified inspection systems.

Goal: Keep the metallic tone (silver, gold, brushed) uniform in every batch.

3. Adhesion & Peel Strength Test

The most critical test checks the adhesion of the metallic layer to different surfaces.

Standard: ASTM D3330 / ISO 29862.

Requirement: ≥ 1.5 N/cm peel strength after curing for 24 hours.

Purpose: Ensure long-term stability on substrates like aluminum, ABS, and painted surfaces.

Adhesion results can vary depending on surface energy; samples are tested on the client’s actual material when available.

4. Environmental & Aging Tests

Metal transfer stickers are subjected to accelerated weathering and environmental simulations:

| Test Type | Condition | Purpose |

| Temperature Cycle | -20°C to 80°C, 6 cycles | Ensures dimensional and color stability |

| UV Exposure | 300 hours under UV lamp | Confirms colorfastness and gloss retention |

| Humidity Test | 40°C, 90% RH for 72 h | Evaluates resistance to moisture and peeling |

| Chemical Resistance | Exposure to alcohol, detergent, mild solvents |

Tests coating durability |

These tests simulate years of actual use in both indoor and outdoor environments.

5. Visual & Dimensional Inspection

After production, each roll or sheet is inspected for:

- Burr-free edges and accurate cutting

- Uniform metallic reflection

- Absence of bubbles, wrinkles, or dust inclusion

- Dimensional tolerance within ±0.1 mm

Advanced inspection systems and trained QC staff ensure every logo or badge meets premium visual standards.

6. Final Sampling & Traceability

Before shipment, samples from every lot are sealed and archived for traceability. Each package includes:

- Material batch code

- Production date

- QC inspector signature

- Certificate of compliance (if requested)

This ensures accountability and simplifies after-sales service or repeat orders.

7. Certifications

Manufacturing facilities can provide certification and testing reports upon request:

- ISO 9001: Quality management system

- SGS / RoHS / REACH: Environmental and safety compliance

- Custom QC Reports: Adhesion, color, and dimensional data for OEM projects

11. Metal Transfer Stickers Cost Factors & Pricing Guide

The total cost of metal transfer stickers is governed by a series of interconnected variables that dictate appearance, performance, and simplicity of manufacture. Familiarity with them allows buyers to make informed choices and to effectively communicate with suppliers.

1. Material Type & Finish

The choice of material is the primary cost driver.

Unprinted aluminum or PET metal film offers a cost-effective option for basic branding.

Brushed, mirror, or anodized finishes require specialty processing, which increases the cost but also visual effect.

Special metallic finishes (copper, rose gold, black chrome) or texture finishes also create additional value for premium brands.

2. Adhesive & Durability Requirements

Adhesive selection affects performance as well as cost. Permanent, heat-resistant, or outdoor-rated adhesives are more costly than standard indoor glues but offer long-term stability on challenging surfaces like aluminum housings or glass.

3. Printing & Processing Complexity

Multi-layer printing, ultra-fine detail, or embossed effects require more precise tooling and quality control, contributing marginally to setup and production costs.

For large-format designs or precision logos, die-cutting precision and waste control also influence overall cost.

4. Quantity & Batch Size

As with most industrial products, larger batch sizes significantly reduce the per-unit cost due to optimized material utilization and amortized setup time.

Typical pricing tiers may include:

Prototype or small batch (≤1,000 pcs): higher unit cost due to setup fees.

Medium batch (5,000–10,000 pcs): balanced cost-efficiency.

Mass production (20,000+ pcs): lowest per-unit cost.

5. Dimensions & Design Complexity

Complex shapes or very fine logos require custom cutting dies or lasers. Simple rectangular or circular shapes are cheaper, and complicated designs increase labor and alignment accuracy time.

6. Packaging & Logistics

Packaging (sheets, rolls, or singles) affects handling cost. For export orders, foreign freight and protective packaging (from bending or scratching) are included in overall quotations.

7. Additional Cost Variables

Other considerations include surface pre-treatment, certification requirements (RoHS, REACH, ISO), and quality reports or third-party testing as required by the customer.

Example:

A standard silver metal transfer sticker (50×20 mm) with permanent adhesive in an order of 10,000 units may cost $0.03–$0.05 per unit (EXW China), while a brushed gold or two-tone finish with heat-resistant adhesive can reach up to $0.07–$0.10 per unit.

12. How to Work with a Metal Transfer Sticker Supplier?

Cooperating closely with your supplier ensures problem-free production, accurate results, and on-time delivery. No matter if you are an OEM producer, brand owner, or pack designer, following a clearly defined communication process will allow you to achieve the best from your project.

1. Define Your Requirements Clearly

Have a complete specification sheet ready before contacting us with:

- Material and finish: e.g., mirror silver, brushed gold, matte black chrome.

- Size and shape: width, height, and corner radius or contour details.

- Adhesive type: permanent, removable, or heat-resistant.

- Application surface: aluminum, ABS, glass, or painted substrate.

- Quantity and packaging format: in sheet, roll, or unit quantities.

A clear spec sheet allows your supplier to select the correct film, adhesive, and transfer process.

2. Request Samples or Prototype Proofs

Ask for material samples or pre-production prototypes to verify appearance, adhesion strength, and color consistency.

-

Digital proofs confirm design registration.

-

Physical samples test real-world performance on your surface.

Most suppliers offer cheap or refundable sampling to accelerate approval.

3. Confirm Quotation and Lead Time

Once samples are approved, lock in all commercial terms before production:

- Payment terms (e.g., T/T, PayPal)

- Lead time and shipping method (air, sea, courier)

- Packaging and marking details

On large OEM projects, suppliers may offer batch delivery options or rolling production schedules.

4. Approve the Production Confirmation Sheet

Your professional suppliers will send a Production Confirmation Sheet specifying all details of your order, material code, adhesive grade, finish, size, and artwork position.

5. Quality Control and Progress Updates

During production, maintain contact with your supplier’s QC department.

-

Request photos or inspection reports of key stages (printing, die-cutting, transfer testing).

-

For large orders, third-party inspection (SGS or Intertek) can guarantee compliance.

Good suppliers provide transparent updates and final inspection reports for traceability.

6. Shipping, Documentation & After-Sales Service

After production is completed, confirm logistics details such as export carton size, HS code, and shipping marks.

Ensure all packages are protected against bending or scratches.

During delivery, conduct incoming inspection and report any issues within the agreed time for prompt support or replacement.

7. Building Long-Term Partnerships

A stable relationship with your supplier benefits both sides:

-

More favorable pricing and material supply stability.

-

Faster sampling and custom technical solutions.

-

Priority scheduling during your peak production seasons.

Stable partnerships enable you to guarantee consistency of quality across multiple product lines and markets.

When selecting a long-term supplier, look for not only price but also communication efficiency, sampling accuracy, and process transparency, these are the best indicators of a truly professional manufacturing partner.

13. Conclusion

In short, metal transfer stickers have definitely lived up to being a great choice. Their special features and advantages distinguish them from normal stickers, and they are thus the first choice for individuals who wish to make a lasting impression. Offering a mix of imagination and visual stimulation, these stickers turn out to be an excellent solution in the market of personalization and branding, bringing any project to new heights of sophistication and style.

Leave A Comment