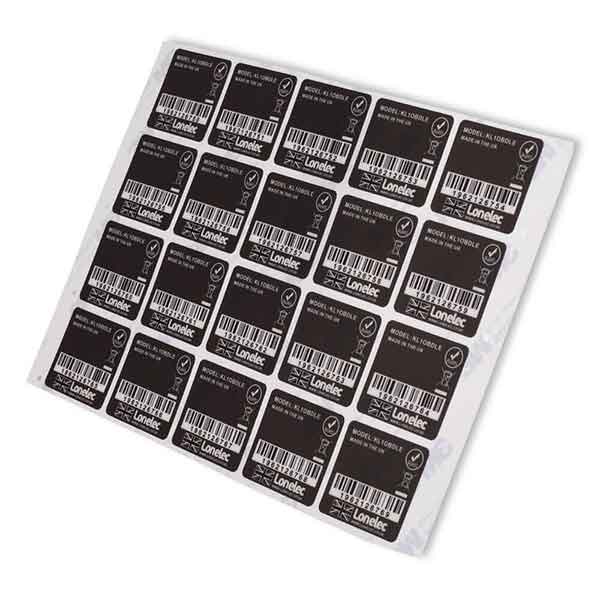

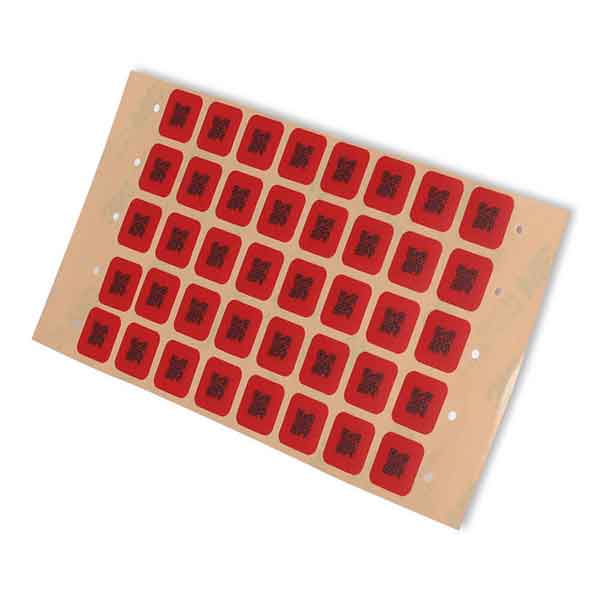

Our label or overlay can print with unique barcode or QR code, This enables branding and product identification on a single label, and this label made of PET or Polycarbonate(PC) ,It can withstand extreme weather conditions, such as water, dust, and oil, which is not possible with ordinary paper labels.

- 100% new material

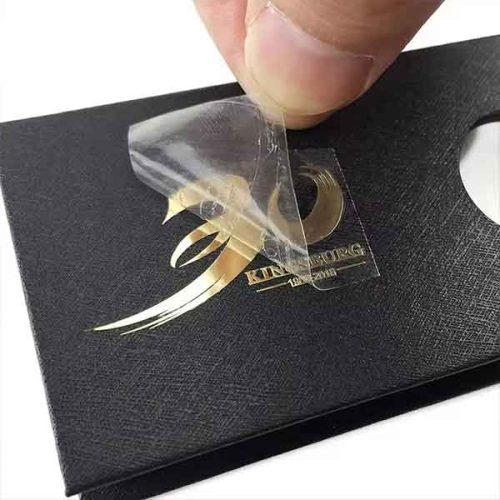

- Clear Windows or cut out die parts

- High-quality printing with cut-out parts and adhesive

- Precision die-cut service with smooth edges as design and good transparency

- Design, printing, die cutting services in one

- No MOQ, no mold tooling extra charge fee