Electronic products have strict requirements for the precision of die-cutting labels, and excessive errors will seriously affect the aesthetic of products, Sometimes this can cause functional problems. We have cutting-edge equipment to ensure the best quality.

- 100% new material

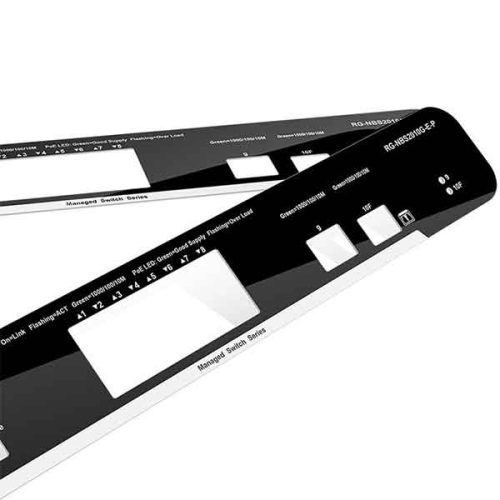

- Clear Windows or cut out die parts

- High-quality printing with cut-out parts and adhesive

- Design, printing, and cutting services in one

- No MOQ, no mold tooling extra charge fee

- Precision die-cut service with smooth edges as design and good transparency