Description

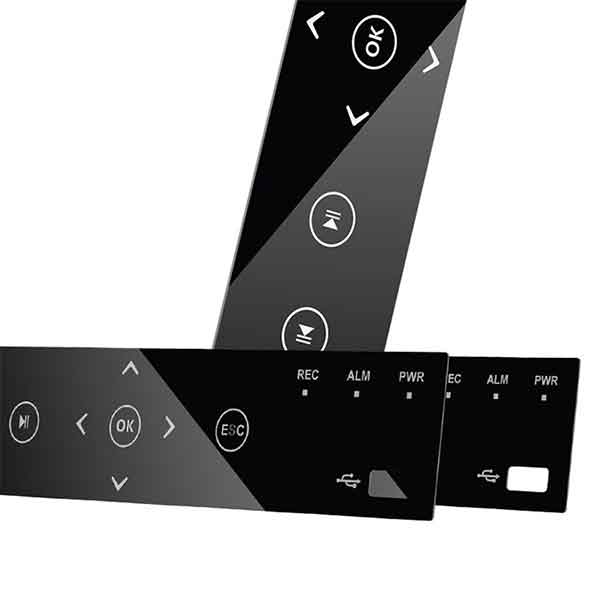

Polycarbonate graphic overlays provides both a protective surface and a communication platform to create a user-friendly, purposeful and well-designed customer interface for branding and functionality.

Polycarbonate graphic overlays are suitable for the solution that requires lots of cut-outs or embossed raised areas, or graphic overlays with many buttons, or graphic overlay with LEDs or windows.

Features

| Product name |

Polycarbonate graphic overlays |

| Material |

Polycarbonate (PC) |

| Thickness |

0.125mm–2.0mm or inform us your requests |

| Finish |

Glossy, frosted, matte, brush finish |

| Application |

Widely used in the external parts of duplicator, telephone, fax machine, DVD, car audio,

domestic air conditioning, medical and health care instruments. |

| Certification |

ISO9001:2015 & ISO14001:2015 for our factory

For material:

MSDS and TDS and SGS data certificates are available |

Order FAQ

Polycarbonate graphic overlays delivery, shipping, and service:

- Lead time: 3 working days for samples and 7 working days for orders;

- Shipping: by express, by air, or by sea, door-to-service would be available

- Service: design, printing, and die-cutting service in one-stop

Q: What format of design file should be provided by you?

A: AI, PDF, COREL DRAW, CAD, vector files first

Q: Can you do OEM service?

A: Yes! Our factory deals with the OEM orders since 2005

Q: What is your minimum order quantity?

A: No MOQ, but the order’s quantity would affect the unit cost

Q: How can I pay for my order?

A: Bank transfer(T/T), Western Union, PayPal, the payment should be paid as the confirmation of orders