Membrane Switch keypads are well-suited for portable medical electronics and require high visibility. Membrane switches are particularly suitable for handheld medical applications and portable devices because they are lightweight, low profile, durable, easy to clean, and RoHS-compliant.

Waterproof Membrane Switch

Description

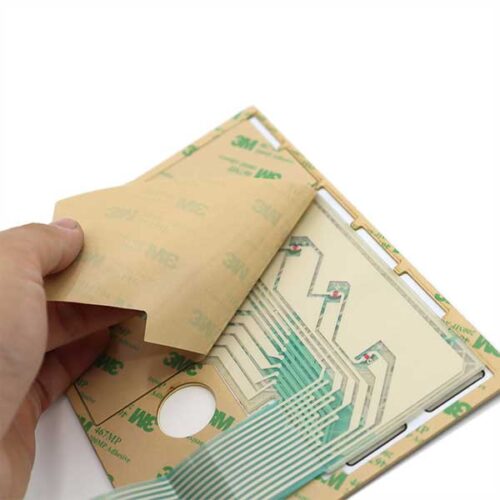

Membrane switches offer numerous design options that enable manufacturers to develop appropriate interfaces that link the end user to the machine’s functionality. A typical membrane switch assembly contains several layers which all serve a distinct purpose for the entire membrane switch, these layers include:

- Graphic overlay- 0.15/0.20mm

- Overlay adhesive-0.1/0.2mm

- Top circuit layer-0.1mm

- Circuit spacer-0.1/0.2mm

- Lower circuit layer-0.1mm

- Rear adhesive layer-3M 467 468

- Rigid support layer-Custom demand

Key Features

- Embossing button

- Circuit encoding

- Hard coat finishes

- Tactile feedback

- Tinted windows

- LED Backlighting

- Panel interconnections

- Subpanels

- Elastomer keypads