Resin domed labels have proven to be a breakthrough in the universe of product labeling and branding, offering a wonderful blend of form, strength, and versatility. In this lengthy guide, we walk you through all the ins and outs of resin domed labels from their composition and manufacturing process intricacies to their extensive applications and numerous advantages. Be you an entrepreneur wanting to thrust your brand into the limelight or a consumer with a penchant for personalized items, this guide is the torch to walk you through the fascinating realm of resin domed labels.

1. What are resin domed labels?

Resin domed labels are labels having a typical clear, domed resin coating on the face. Typically constructed from polyurethane or epoxy resin, the resin layer not only improves the visual beauty of the label but also bestows a wide range of functional advantages on it. Valued for their resistance to a great number of environmental conditions, three-dimensional look, and high-gloss finish, resin domed labels have gained a strong position as a greatly sought-after solution for product labeling, branding, and decoration purposes.

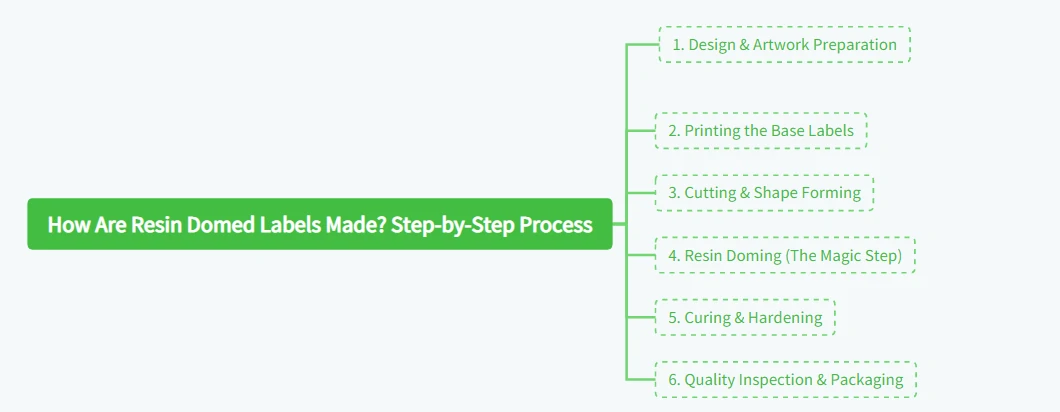

2. How Are Resin Domed Labels Made? Step-by-Step Process

If you have ever been curious about how these shiny 3D labels are produced, you’ll have a behind-the-scenes look at the production process. This allows you to appreciate lead times, quality, and what to anticipate when you order custom resin domed labels.

1. Design & Artwork Preparation

Every order starts with a design file (AI, PDF, or vector artwork). The manufacturer checks size, color layers, cut lines, and bleed margins to ensure your logo or graphic will dome evenly once the resin is applied.

2. Printing the Base Labels

- The artwork is digitally or screen printed onto durable substrates such as polyester (PET) or vinyl (PVC).

- Digital print is most suitable for small runs with deep color gradients.

- Screen printing gives solid, rich colors ideal for logos and brand marks.

3. Cutting & Shape Forming

Printing is followed by sheets being die-cut or laser-cut into individual labels, circular, rectangular, or entirely custom shapes. Smooth edges are a must so the resin drips down stunningly to the edge.

4. Resin Doming (The Magic Step)

A clear polyurethane (PU) or epoxy resin is dispensed onto each label. The resin self-levels, creating that smooth, domed “liquid glass” look. PU is preferred for high-end labels because it stays crystal clear without yellowing.

5. Curing & Hardening

The domed labels are placed in a controlled environment to cure for 12–24 hours. During this time, the resin hardens and forms a glossy, protective 3D surface.

6. Quality Inspection & Packaging

All of the labels are inspected for bubbles, abnormal doming, color uniformity, and clarity prior to packaging. Labels are typically provided in sheets, rolls, or individually, subject to application requirements.

Lead time: 7–10 days for standard orders, 2–3 weeks for large or complex runs.

3. Resin Domed Labels Design Tips & Mistakes to Avoid

Even small design tweaks can make a big difference in quality and cost. Here’s what professionals recommend:

You can do this

- Use vector artwork (AI/PDF/SVG) for crisp printing.

- Keep text bold and simple; fine details may blur under the resin.

- Add rounded corners; sharp edges can causing resin to overflow.

- Plan bleed and spacing so resin has room to dome naturally.

- Test samples first before committing to mass production.

You should avoid this

- Extremely thin lines or tiny fonts (less than 0.8 mm stroke width).

- Overly complex shapes with narrow tips or tight corners.

- Using low-quality resin, it may yellow or crack in sunlight.

- Forgetting to test adhesion before applying to curved surfaces.

A well-prepared design not only saves money but ensures perfect, bubble-free domes every time.

4. Types of resin domed labels

The type of resin domed labels encompasses an extensive variety of types, based on the purity of resin applied and the intricacies of manufacture. A sneak peek at some typical types of resin domed labels is provided below:

1) Polyurethane resin domed labels

Pros: resin domed labels boast a soft texture, exceptional transparency, and resistance to yellowing.

Cons: resin domed labels tend to incur a higher cost and exhibit relatively lower hardness compared to epoxy resin counterparts.

2) Epoxy resin domed labels

Advantages: resin domed labels are characterized by high hardness, commendable chemical resistance, and inexpensiveness.

Disadvantages: resin domed labels are featured by slightly compromised transparency and inclination to yellow over extended periods.

3) UV 3D domed labels

Pros: 3D domed labels feature a rapid curing process, superior transparency, and eco-friendly attributes.

Cons: 3D domed labels mandate specialized UV curing equipment, initial cost implications.

5. Advantages of resin domed labels

The beauty of resin domed labels lies in the extensive range of advantages they offer, making them a popular choice in several applications:

1) Robustness

The tough resin coating of resin domed labels offers better wear and tear resistance, thus the labels look more beautiful for longer durations.

2) Visual appeal

The domed, transparent resin coating gives the labels an interesting three-dimensional look, making them look more beautiful and contributing to the overall look of the product.

3) Weather resistance

resin domed labels possess good resistance to UV light, water, and temperature fluctuation, and thus can be applied both indoors and outdoors.

4) Flexibility

These resin-domed labels are conducive to high degrees of customization in shape, size, color, and appearance, giving unlimited scope for product labeling and branding activities.

6. Disadvantages of resin domed labels

Though the advantages of resin domed labels are numerous, there are certain disadvantages that lie with them:

1) Production cost

The intricate manufacturing process of resin domed labels can translate into elevated production costs vis-a-vis conventional labels.

2) Production time

The curing duration of the resin can prolong the production cycles of resin-domed labels, necessitating patience, and meticulous planning.

3) Environmental concerns

Certain resin materials utilized in resin-domed labels release poisonous elements during curing, leading to environmental issues. However, UV resin emerges as a more environmentally friendly option.

7. Applications of resin domed labels

resin domed labels find versatile applications across a spectrum of industries and settings, including but not limited to:

1) Brand logos

Instrumental in crafting eye-catching logos for products and packaging, thereby amplifying brand visibility and recognition.

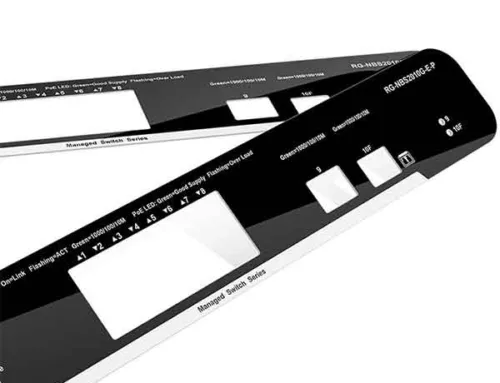

2) Industrial labels

Deployed equipment, machinery, and control panels to furnish durable and enduring labeling solutions.

3) Promotional products

Utilized as part of promotion products, gifts, and merchandise to provide an upscale appearance and texture.

4) Automotive industry

A standard go-to for car emblems, dashboard indicators, and car badges because of their durability and weather-resistant nature.

8. Resin Domed Labels vs. Other Label Types

It’s easy to get domed labels confused with other labels. Let’s have a brief recap to assist you in choosing the ideal one:

| Feature | Resin Domed Labels | Flat Vinyl Labels | Metal Nameplates | Printed Graphic Overlays |

| Appearance | Glossy 3D look | Flat matte or gloss | Metallic or brushed | Printed, customizable |

| Durability | UV, scratch & weather resistant | Basic indoor use | Extremely durable | High durability, sealed |

| Flexibility | Flexible | Flexible | Rigid | Flexible |

| Tactile Feel | Raised, smooth dome | Flat surface | Solid metal texture | Smooth, optional texture |

| Best Use | Branding, product logos, promotional items | Simple labeling | Industrial machinery, long-term ID | Control panels, equipment faceplates |

| Cost | $$ | $ | $$$ | $$$ |

If you’re after a premium, eye-catching label that adds perceived value to your product, resin domed labels are the best choice.

9. How to choose resin domed labels?

When navigating the realm of resin domed labels to select the ideal fit for your unique requisites, consider the following pivotal factors:

1) Usage environment

Select a resin type that matches the environmental situation in which the labels will be subjected to, e.g., UV resistance for exterior use.

2) Cost considerations

Balance the performance advantages of the resin with the overall cost to ensure it fits your budget constraints and company needs.

3) Brand image

Select resin domed labels that align with your brand values and messaging, contributing to the world-wide visual attractiveness of your product and enhancing brand identity.

4) Environmental impact

For those who place importance on sustainable methods, UV resin domed labels are a responsible choice, offering a more environmentally friendly option.

10. Cost Factors & Pricing Guide of resin domed labels

Pricing for resin domed labels varies depending on size, material, and design complexity. Here are the key cost drivers:

1. Label Size & Shape

Larger labels require more resin and take longer to cure.

Complex shapes (custom contours, rounded corners) require additional tooling.

2. Material & Adhesive Choice

Vinyl (PVC) is economical and flexible.

PET (Polyester) offers better durability and chemical resistance.

3M adhesives or outdoor-grade options increase cost but improve lifespan.

3. Printing Method

Digital printing: Great for small runs, slightly higher per-unit cost.

Screen printing: Lower unit cost for mass production.

4. Resin Type

Polyurethane (PU): Premium quality, non-yellowing.

Epoxy: Cheaper but may yellow over time.

5. Quantity

- Small runs (100–500 pcs): $0.20–$0.50 per piece.

- Large orders (5,000+ pcs): $0.05–$0.15 per piece.

- Complex shapes + PU resin: $0.50–$1.50 per piece.

6. Special Finishes

Metallic inks, clear windows, holographic layers, or anti-counterfeit serials add 10–30% to cost.

Reveal your end use and environment (indoor/outdoor, chemical or UV exposure) to your supplier they can recommend materials that balance cost vs. performance

11. Quality Control & Testing Standards of Resin-Domed Labels

High-quality domed labels are subjected to a number of tests before shipping to guarantee performance and consistency.

1. Bubble & Surface Inspection

Each label examined for air entrapment or resin spill-over.

2. Adhesion Test

Confirms strong adhesion to substrate materials.

3. UV Aging Test

Simulates prolonged sun exposure for outdoor use.

4. Abrasion & Scratch Resistance Test

Ensures surface won’t dull or chip readily.

5. Dimensional Tolerance Check

Inspects shape accuracy and dome evenness.

ISO 9001 compliant factories usually keep batch samples for 12 months for long-term traceability.

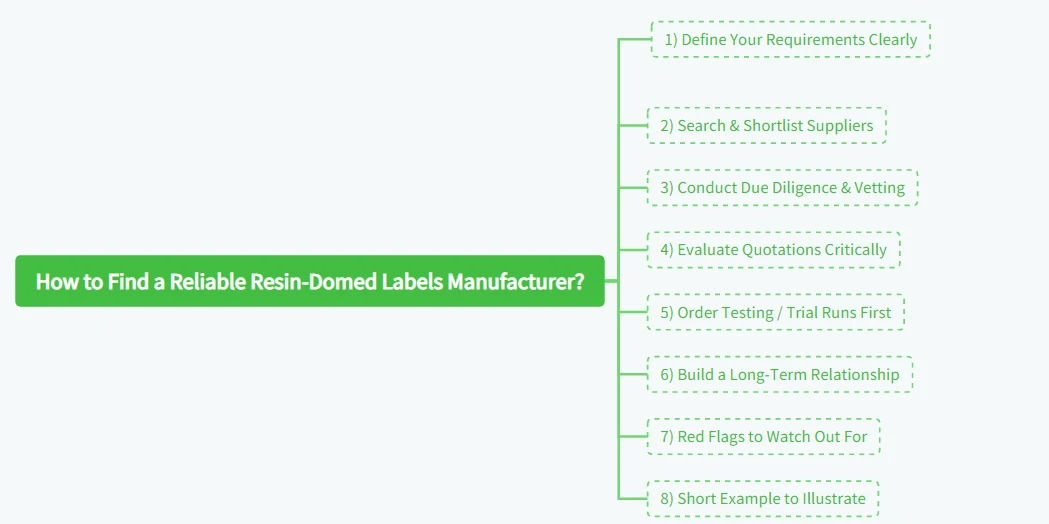

12. How to Find a Reliable Resin-Domed Labels Manufacturer?

Choosing the right manufacturer can make or break your product’s quality, lead time, and cost. The following are step-by-step instructions and due diligence checklist to help you choose a good supplier.

1) Define Your Requirements Clearly

Before going to manufacturers, have a clear spec sheet with:

- Size, shape, and thickness

- Material preference (PVC, PET, etc.)

- Resin type (PU or epoxy)

- Adhesive type (3M, standard, removable)

- Printing requirements (number of colors, special inks)

- Surface finish (matte, gloss, textured)

- Anticipated lead time and quantity

- Application environment (temperature range, chemicals, UV exposure, outdoor, indoor)

Having this spec sheet in your pocket makes it simple to screen out suppliers who claim they can provide what you require.

2) Search & Shortlist Suppliers

Some channels and strategies:

- Industry marketplaces like Alibaba / Global Sources — look for “polyurethane resin domed labels” listings.

- Trade shows & exhibitions (e.g. labeling, packaging, electronics fairs) — on-site inspections build confidence

- Referrals & peer networks — ask other product OEMs or contacts in your industry

- Google / LinkedIn — search manufacturers or factories showing their doming capabilities

- Existing domed label brands — check who they source from (e.g. some brands like MSTR, TLP, Mockridge label this capacity)

3) Conduct Due Diligence & Vetting

When you’ve got a few candidate manufacturers, vet them systematically:

| Check Item | Why It Matters | What to Ask / Verify |

| Factory Visit / Video Tour | See actual production | Do they have doming machines? How many? |

| Equipment & Capacity | To avoid bottlenecks | What resin dispensing & curing equipment do they use? |

| Sample & Prototyping | Quality proof before mass | Request a sample using your exact spec |

| Certifications & Quality Systems | For reliability | ISO 9001, RoHS, UL, etc. |

| Reference Customers / Portfolio | To see real work | Ask for past projects, photos or client references |

| Lead Time & Delivery Performance | For planning | Ask for typical turnaround on your spec |

| Communication & Responsiveness | Smooth working relationship | How fast do they reply? Do they ask thoughtful questions? |

| After-sales / Warranty | To mitigate defects | What are their defect replacement policies? |

4) Evaluate Quotations Critically

When suppliers send you quotes, don’t just pick the lowest. Compare line by line:

- Setup / tooling fees

- Material cost (substrate, resin, adhesive)

- Printing cost

- Doming / resin dispensing cost

- Curing time & energy costs

- Packaging/logistics

- Minimum order quantity (MOQ)

- Payment terms, risk margins

Ask for the landed cost to your factory/warehouse (including freight, import duty). Sometimes, a slightly higher unit price but a closer location is cheaper overall.

5) Order Testing / Trial Runs First

Before you commit to full production:

- Order a small batch test with your full spec

- Inspect for visual defects, bubble, resin clarity, adhesion strength

- Test in actual conditions: heat, humidity, sunlight, chemicals

- Use it on your final product (simulate real use)

If everything passes, then go ahead with the full run.

6) Build a Long-Term Relationship

Once you find a good manufacturer:

- Lock in pricing tiers for future orders

- Maintain open communication — share forecast volumes, design changes early

- Request them to stock materials and coolers for faster turnaround

- Ask them to reserve capacity / prioritize your orders when possible

- Periodically audit their QC performance

7) Red Flags to Watch Out For

Be cautious if:

- They refuse to provide real samples or factory images

- Their pricing is unbelievably low for your spec

- They avoid answering technical questions (resin brand, curing method)

- Lead times are vague or constantly shifting

- Poor English / communication (unless you have local oversight)

8) Short Example to Illustrate

Suppose you need a 1000-piece batch of 5 cm PET labels, 1.8 mm PU dome, full-color print, and outdoor usage.

You send this spec to 3 manufacturers.

- Supplier A quotes $0.20/pc, but MOQ 5000, and uses epoxy.

- Supplier B quotes $0.35/pc, MOQ 1000, uses automotive PU, has quality certifications, and is responsive.

- Supplier C quotes $0.18/pc, MOQ 500, but refuses to send a full spec sample, delays answers.

You would likely choose Supplier B, even though it’s not the cheapest; they balance capability, trust, and quality.

13. Resin domed label FAQs

The following are some common questions about resin domed labels.

1) Are resin domed labels Waterproof?

Yes, resin domed labels exhibit waterproof properties, rendering them apt for deployment in damp or outdoor environments.

2) What is the Lifespan of resin domed labels?

resin domed labels boast a lifespan ranging from 5 to 10 years, contingent upon the quality of the resin and the maintenance regimen adhered to.

3) Can resin domed labels be Applied to Curved Surfaces?

Indeed, resin domed labels possess the flexibility to conform to curved surfaces, provided the surface is pristine and devoid of debris for optimal adhesion.

4) Do resin domed labels Yellow Over Time?

Polyurethane resin domed labels showcase resistance to yellowing, whereas epoxy resin labels may exhibit slight yellowing with prolonged exposure to sunlight.

5) How Long Does it Take to Produce resin domed labels?

The production timeline for resin domed labels can fluctuate based on the curing process and intricacy of the design, typically spanning from 3 to 7 days.

14. Conclusion

Resin domed labels recall an imaginary gemstone of labeling and branding with visual attractiveness, durability, and flexibility to fit in custom. By going through resin domed labels by categories, advantages and disadvantages, applications, and selecting standards, you equip yourself with knowledge to make educated decisions that suit your own needs and specifications.

If you want to elevate the status of your brand, or add a bit of personal touch to your products, resin domed labels are here and ready to be a source of opulent addition to your branding and labelling endeavors. We wish that from this comprehensive guide, you have been sufficiently supplied with beneficial information and knowledge that will navigate you through the intriguing world of resin domed labels smoothly and with precision, such that you are able to make sound decisions that will coexist harmoniously with your branding ideas and product label purposes.

This article presents an accessible yet detailed introduction to resin domed labels, outlining their structure, materials, and key benefits in an easily understandable fashion. I particularly appreciated its ability to tie technical aspects like polyurethane or epoxy resin composition together with practical uses in branding and decoration. The writing style makes complex information easily understood – this makes the article particularly beneficial for businesses exploring durable yet visually appealing labeling solutions for product designs. Overall, it was an incredibly informative guide which helps readers gain an appreciation of why such labels have become such a part of product design today.

This guide on resin domed labels is very insightful and well-written, providing clear explanations on their components, materials, uses, and popularity among brands and product decoration companies. I really appreciated how the article tied technical details–such as using polyurethane or epoxy resin–to practical benefits such as durability, 3D appearance and gloss finish – providing designers and manufacturers an ideal introduction for understanding both aesthetics and functionality of domed labels; overall this resource makes an excellent start when considering modern labeling solutions.