In an branded universe of packaging supremacy, there is one commonly-underestimated hero that quietly grabs center stage: roll labels. These unassuming-yet-powerful sticky heroes become all about product presentation, brand recognition, and customer engagement. Join us on a tour through the universe of roll labels and we’ll delve into all things about these behind-the-scenes superheroes of the packaging universe.

1. What are Roll Labels?

A roll label is an adhesive sticker that is placed on or wrapped around a cylindrical core. They are printed on a customized printer and rolled onto a 3-inch cardboard spindle.

The process of printing on the roll labels results in many stickers that are easily removable from the roll and are attached to the desired surface. Their popularity is due to the fact that they are pre-made and are easily placed, thus making them the ideal solution to label many kinds of products.

2. Roll Label Composition

A roll label comprises several essential components or layers arranged on a cylindrical core, including the face stock, adhesive, liner, top coat, and core. Let’s delve into the composition of a roll label:

1) Face Stock

The face stock serves as the canvas for the label’s design. Positioned over the adhesive layer, it is the exposed surface of the roll label. Face stock can be constructed of a number of varying materials, such as paper, film, fabric, and foil, with these being the most common.

2) Adhesive

The adhesive coating provides the label with its adhesive strength. Attached to the liner, it is simple to remove for easy sticking on the desired surface. Roll labels employ a broad range of adhesives, which can be all-temperature, cold-temperature, permanent, or removable adhesives.

The adhesive employs a mix of materials in order to impart strong adhesion and prevent delamination.

3) Liner

The backing, liner, or carrier is the material holding the adhesive and holding it in place until the label may be used.

Typically kraft paper with a specially coated surface, often silicone, liners provide a simple release of the adhesive. Liners may also be formulated using materials such as polyethylene terephthalate.

4) Top Coat

Acting as a guard for the label, the top coat is an additional coating put on for increased durability. Although not on each roll label, it is typically added to prevent face stock from getting scratched, as well as to prevent other damage.

Top coats can be varying types, from glossy to matte, and give the label’s overall design an extra layer.

5) Core

As the strong backbone of a roll label, the core is a stiff cardboard center providing structural strength. Think of it as the cardboard tube found in a roll of tissue paper. Cores are available in various sizes, depending on the label application equipment used. They typically have 1-inch or 3-inch diameters.

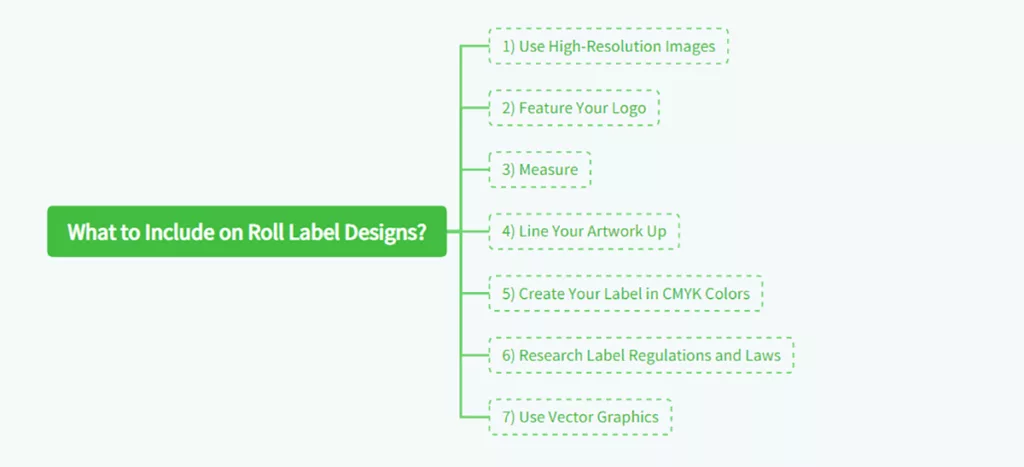

3. What to Include on Roll Label Designs?

Within the rich tapestry of product presentation, roll label designs emerge as the unsung artisans of brand narrative. From bold imagery to crucial information, each element meticulously created on these pressure-sensitive surfaces is a decisive agent in attracting consumer attention and conveying brand personality. Take a stroll through the intricate realm of roll label graphics, where every detail can make a lasting mark on shelves and in customers’ hearts.

1) Use High-Resolution Images

Opt for high-resolution images in your label design endeavors to exude a professional and sharp aesthetic. Remember that, use JPEG files for optimal print quality because PNG and GIF files may not translate properly in high resolution. Attempt to retain all images above 300 dpi to ensure perfect clarity.

2) Feature Your Logo

Set your brand logo on the front of your own personalized label. Locate it centrally at the middle or near the top of the design so that its size is prominent compared to other graphics.

3) Measure

Accurate measurement of your product container size is essential for correct sizing during production. Adhering to meticulous measurements opens the door for smooth production and avoids size changes. Our BOPP labels are standardized with a 3″ core and an outer diameter of up to 6″.

4) Line Your Artwork Up

Harness the ruler tool within your design software to align artwork, text, and all components of your custom label. This meticulous alignment ensures a polished and professional appearance for your design.

5) Create Your Label in CMYK Colors

Use the CMYK color model, cyan, magenta, yellow, and black, now the industry standard for label printing. Avoid the RGB colors, utilized primarily for web use, as they may alter the actual color meaning of your design once printed.

6) Research Label Regulations and Laws

Certain products, especially in the food industry, must adhere to specific labeling regulations. Put research into these regulations at the beginning of your process of making decisions to prevent any potential future legal issues.

7) Use Vector Graphics

Distinguish yourself by leveraging vector graphics over raster counterparts, favored for their ability to maintain image quality and prevent pixelation even when scaled.

These informative guidelines are your blueprint to guide your own custom roll label production. With a deeper knowledge of label design subtleties, let creativity run wild and leave the doing to us to make your top-notch roll-label aspirations a reality. If you require assistance with design, our tailor-made graphic design abilities are available to assist in taking your label production to new heights.

4. What are the Best Sizes, Shapes, and Materials for Custom Roll Labels?

In selecting optimal specifications for custom roll labels, selecting the ideal size, form, and materials is a prime factor in providing an attractive and effective final product.

To most businesses, rectangular labels are oftentimes the preferred first option since they are convenient and versatile. With their wide surface area, plenty of room is available to convey important information, hence can accommodate any amount of uses, whether product marking or promotion mailers.

But for those who desire something more original and creative attraction that best represents your brand image, custom-cut stickers are an extremely appealing option. With the possibility of selecting an alternate custom shape that mirrors your company name or logo precisely, these stickers offer a level of customization that differentiates your brand from others.

In seeking green label alternatives, it is essential to stress more on materials that adhere to sustainability standards and minimize damage to the environment. Compared to regular stickers which may contain plastic films and non-recyclable adhesives, using alternatives such as MSTR’s Custom Roll Labels can contribute significantly.From environmentally friendly materials and non-toxic glue and ink labels, the labels are not only environment-friendly and safe for consumers but also represent a responsible business culture.

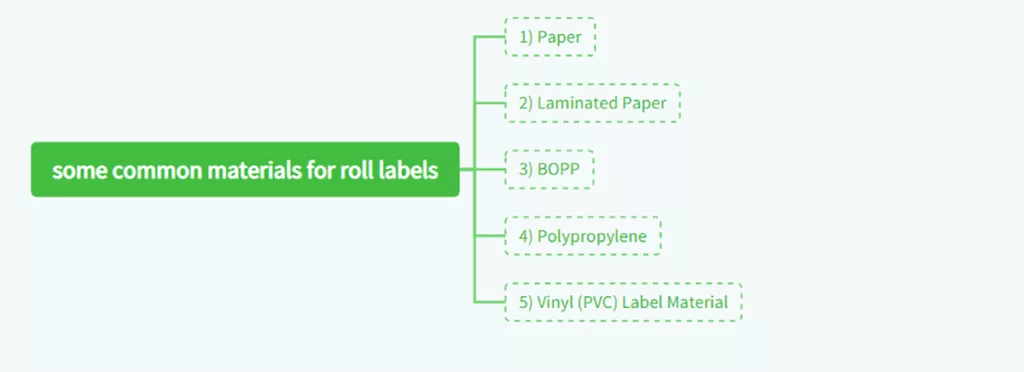

Roll labels take a large range of different materials to create, each possessing special characteristics that will decide the appearance of the label, print quality, and durability. The following are some common materials for roll labels.

1) Paper

Among the foundational materials for roll labels is paper, known for its affordability compared to other options. While not inherently resistant to oil or water, making it less durable, paper remains a favored choice for businesses seeking environmentally conscious label designs for their sustainable products.

2) Laminated Paper

For an added level of durability, laminated paper offers an adequate alternative to ordinary paper labels. With a liquid and humidity-proof covering coating, laminated paper is more resilient than plain paper.

3) BOPP

Biaxially-oriented polypropylene (BOPP) is a good label film for personal and beauty care, food, and beverage packaging due to its strength and versatility. Water and oil proof, BOPP labels usually possess a permanent adhesive for long lasting and secure adhesion. Variants include clear, white, and removable BOPP options.

4) Polypropylene

Similar to BOPP, polypropylene is especially a water-resistant, tear-proof sheet material ideally used to make high-quality, long-lasting labels that are not influenced by extended exposure to water, oil, and moisture without compromising the quality of print. Polypropylene offers protection from yellowing and color fading, keeping the design intact early in the product’s life cycle.

5) Vinyl (PVC) Label Material

Vinyl roll labels offer greater durability because they are water resistant, chemical resistant, and UV resistant. Suitable for outdoor items or those that experience constant exposure to the elements, vinyl labels are not just durable but can also be paired with a heavy-duty adhesive that is perfect for application on sharp and curved surfaces.

5. Printing & Customization Options of Roll Labels

Selecting the appropriate print process and level of customization is essential to achieving the right visual effect and performance requirements in roll labels. Each print process has advantages and disadvantages in cost, color accuracy, and quantity of order. The key options are briefly summarized below:

1. Digital Printing

Digital printing offers sharp high-resolution output with good color quality, ideal for small to mid-size batch or variable design runs.

- Advantages: No plate charge, fast turnaround, allows variable data (QR codes, serial numbers).

- Best for: Short runs, private-label applications, high design frequencies.

- Typical materials: Paper, PP, PET, and vinyl films.

2. Flexographic Printing

Flexographic printing uses flexible plates and fast-drying inks and is best suited for large volume runs with good consistency.

- Strengths: High-speed operation, stable ink retention, cost-effective for large volumes.

- Best used for: Food, drink, and logistics packaging labels.

- Personalization options: Metallic inks, spot colors, UV coating, and lamination.

3. Thermal Transfer & Direct Thermal Printing

Both of these types of printing are widely used for real-time logistic and barcode printing applications.

- Thermal transfer: Used with a ribbon to provide long-term, smudge-free prints.

- Direct thermal: Ribbon-free, for short-life labels.

- Ideal for use with: Warehousing, shipping, inventory labels.

4. Screen & Specialty Printing

For high-end visual effects or specialty labels, screen printing and hybrid printing technologies are frequently used.

- Strengths: High opacity and tactile effect.

- Effects to be utilized: Embossing, debossing, metallic foiling, matte or gloss varnish.

- Industry recommended for use: Cosmetic, electronics, or promotional product labeling.

5. Finishing & Protective Treatments

Finishing both increases durability as well as appearance, maintaining labels in good condition under functional conditions.

Options include:

- Lamination: Water and scratch-resistant.

- UV Coating: Adds gloss and color depth.

- Cold / Hot Foiling: Metallic or reflective detail.

- Embossing: Creates a luxurious tactile surface.

6. Variable Data & Security Printing

For traceability, branding, and anti-counterfeiting, variable and security printing features can be included:

- Variable data: Serial numbers, batch codes, QR codes.

- Security options: Holographic film, tamper-evident cuts, invisible UV marks.

- Ideal for: Pharmaceutical, electronics, and luxury goods industries.

6. Roll Labels Applications by Industry

Roll labels find use in a wide range of industries, each with a specific material, adhesive, and print requirement. Understanding your product’s environment and label condition provides for both performance and appearance. The following are the most common industrial applications and their label needs:

1. Food & Beverage

Food and beverage packaging labels must be resistant to water, condensation, and temperature change during storage or refrigeration.

- Recommended material: PP, PET, or waterproof lamination vinyl film.

- Adhesive options: Freezer-grade or permanent adhesive for foods stored or maintained in the refrigerator or freezer.

- Common applications: Jar labeling, bottle labeling, nutrition labeling, barcode labeling.

2. Health & Beauty

Cosmetic and personal care products require good appearance and alcohol or oil resistance.

- Recommended material: Gloss or matte PP film, PET, or metallic film.

- Adhesive selection: High-tack adhesive for rounded bottles and squeeze tubes.

- Common applications: Skincare jars, shampoo, lotion tubes, make-up packages.

3. Pharmaceutical & Medical

Pharmaceutical and medical applications call for high print quality, conformity, and precision for safety and traceability.

- Material options: PET film, chemically resistant synthetic materials, or thermal transfer paper.

- Adhesive options: FDA-approved, removable, or tamper-evident adhesives.

- Typical applications: Syringes, vials, prescription bottles, hospital equipment labels.

4. Logistics & Warehousing

For tracking product and supply chain, roll labels must be complemented by automatic labeling machines and barcode readers.

- Material options: Direct thermal or thermal transfer paper.

- Types of adhesives: Chemical and heat resistant adhesive on plastic packaging and cardboard.

- Applications: Tracking pallets, barcode labels, inventory labels, shipping labels.

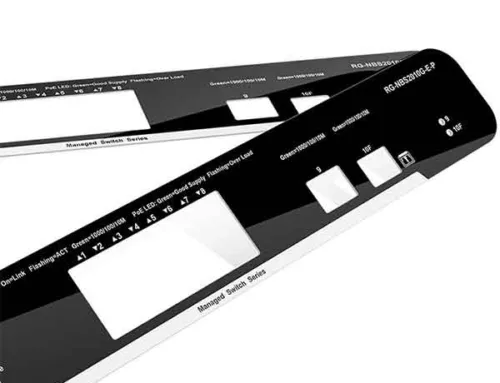

5. Industrial & Manufacturing

Labels used in industrial environments must resist heat, chemicals, and dust exposure.

- Recommended materials: Industrial-strength PET, vinyl, or polyester film.

- Adhesive types: Solvent-resistant or high-temperature adhesive.

- Typical uses: Equipment identification labels, warning labels, asset tags, control panels.

6. Household & Chemical Products

Household products and chemical bottles are exposed to mechanical rough handling and humidity, thus adhesion is of critical significance.

- Material suggestion: Water-resistant PP or PE film.

- Options for adhesives: Permanent chemical-resistant adhesive.

- Typical applications: Spray bottle, detergent containers, auto chemicals.

7. Why would my Business benefit from Custom Roll Labels?

Umbrella Adopting custom roll labels in business activity can provide a vast array of advantages to enhance brand profile and increase customer connection by good design and clever message-making.

Most importantly, however, is that custom labels are an effective branding vehicle. Add your own proprietary design, color, and logo to the mix, and your labels become an on-package manifestation of your firm’s philosophy, creating awareness and loyalty among your consumers.

Beyond branding, custom labels also offer space for creative marketing. Throw in dynamic QR codes that direct your customers to exclusive product promotions or offer step-by-step usage instructions for the product, introducing an element of interactivity to your package. In addition, incorporating Custom Die Cut Stickers provides an edge of class and innovation, making your products stand out in a competitive market environment.

In addition, personalized labels become a billboard for your business and enable you to convey information required such as ingredients, nutrition facts, and storage requirements. Not only does this offer customer experience clarity and guidance, but also enables you to remain regulation compliant when listing of ingredients is obligatory.

In one word, the strategic application of custom roll labels not only makes your brand’s visual impact greater but also allows you to engage customers differently, convey product information well, and meet industry compliance in style and panache.

8. What Factors Do You Have to Look for When Choosing Custom Roll Labels?

Before proceeding with the custom roll label selection process, numerous pertinent factors call for utmost caution so as to accomplish a flawless amalgamation of function, green, and loveliness.

At first, the choice of label material becomes an essential consideration, affecting not only the aesthetic value but also the environmentally friendly footprint of your packaging. Venture into the universe of materials that align with your ethos of sustainable consumption. For MSTR, our Custom Sticker Rolls utilize FSC-certified, acid-free paper, offering a green solution that can be simply composted when done, satisfying environmentally conscious consumers.

Moreover, the lines and shape of your labels matter the most in creating a striking and informative packaging series. Consider the variety of available shapes, from rectangle and square to oval and circle or custom die-cut, to bring an element of innovation and creativity to your brand strategy.

In working your way through the spectrum of sizes, select your choice to match the information load to be conveyed for release on the label. From a small logo to detailed product information, select a size that is consistent with the scope of content, allowing for clarity and visual balance in presentation.

For new businesses and startups, aspects such as minimum order quantities (MOQ) and affordability come into play in thriving in the label buying atmosphere. You should make accessibility a priority by keeping prices competitive and available to low MOQ requirements so that companies can acquire customized label solutions without stretching capital too far.

Essentially, the prudent evaluation of material composition, quantity, shape, and price standards provides businesses with the tools to design customized bespoke roll labels that not only wow customers aesthetically but also address sustainability concerns and operational efficiency.

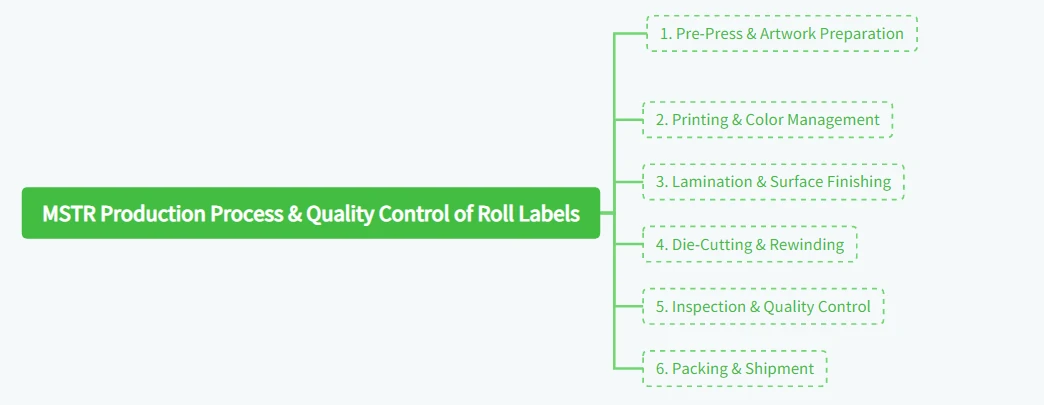

9. MSTR Production Process & Quality Control of Roll Labels

A well-controlled production process ensures consistent quality, accurate die-cutting, and reliable label performance during application. The following is a step-by-step instructional guide on how professional roll label manufacturers produce and quality test each batch:

1. Pre-Press & Artwork Preparation

Artwork supplied by the customer is reviewed for color accuracy, bleed tolerance, and die-line registration. Pantone colors and trapping are verified before printing plates or digital proofs are generated.

Goal: Flawless reproduction and print consistency.

2. Printing & Color Management

Depending on the size of the project, the appropriate printing process, digital, flexographic, or screen, is selected. Color density and registration are continuously checked using spectrophotometers throughout production.

Goal: Maintain consistent tone, saturation, and visual accuracy.

3. Lamination & Surface Finishing

Protective layers of gloss/matte lamination or UV coating are added to enhance durability against water, chemicals, and scratches.

Objective: Extend label life in real use.

4. Die-Cutting & Rewinding

Labels are precision die-cut and rewound to the correct core size, outer diameter, and label orientation for application on automatic labeling machines.

Objective: Deliver flawless compatibility with labeling machines.

5. Inspection & Quality Control

Each roll undergoes 100% inspection for color uniformity, registration match, adhesive consistency, and label spacing. Wrinkles, miscuts, or bubbles are automatically rejected as defects.

Objective: Deliver stable, machine-ready rolls with zero application issues.

6. Packing & Shipment

Rolls are shrink-wrapped or inserted in moisture-proof cartons, duly marked with material type, lot number, and date of production for traceability.

Objective: Ensure safe delivery and easy batch management.

Common Certifications: ISO 9001, SGS, RoHS, and REACH compliance for material and ink.

10. Roll Labels Cost Factors & Pricing Guide

The pricing of roll labels is a function of various design and production factors. Understanding the factors enables buyers to control costs and communicate effectively with suppliers.

1. Material Selection

- Paper: Cost-effective, suitable for indoor use.

- PP / PET film: More durable, waterproof, higher cost.

- Specialty materials: Metallic, clear, or textured film add unit cost.

2. Printing Method

- Digital printing: Perfect for small runs or multiple SKUs (no plate fees).

- Flexographic printing: Cost-effective for large runs.

- Special effects: Foil stamping or embossing increases unit cost.

3. Order Quantity

Higher quantities reduce per-label cost due to setup amortization. Typical MOQ for custom roll labels is 1,000 to 5,000 pcs, depending on design complexity.

4. Label Size & Shape

Custom shapes require custom dies and extra cutting time that are factored into tooling costs. Round and rectangle shapes are the most cost-effective.

5. Adhesive & Finish

Removable or specialty adhesives and laminations (gloss/matte/UV) add to the overall cost but improve performance and appearance.

6. Packaging & Shipping

Costs also differ with roll diameter, core size, and shipping method (air, sea, courier). Voluminous but light shipments may incur volumetric charges.

Example Pricing Breakdown (for reference):

| Factor | Example Option | Approx. Cost Impact |

| Material | Gloss Paper | Low |

| Material | PET Film | 15% |

| Printing | 4C Digital | 10% |

| Lamination | Matte Finish | 5% |

| Quantity | 50,000 pcs+ | -20% |

Tips: When requesting a quote, always include: material, core size, roll direction, quantity per roll, and desired finish. This ensures accurate and fast pricing.

11. How to Work with a Roll Label Supplier?

It saves you time, minimizes errors, and guarantees brand consistency to have a professional roll label supplier. The following is how you can make your cooperation process run more smoothly:

1. Provide Detailed Specifications

Before production, share clear information:

- Label size and shape

- Material and adhesive requirements

- Core size and roll winding direction

- Printing colors and artwork file

- Application environment (temperature, humidity, surface type)

This allows the supplier to confirm material compatibility and quote accurately.

2. Request a Sample or Prototype

A physical sample or digital proof is recommended for trial runs on your labeling equipment. Check print quality, adhesive strength, and sensor response before bulk production.

3. Confirm Order Details

After sample approval, finalize:

- Quantity per roll

- Label orientation

- Packaging method

- Expected lead time and delivery terms (EXW / FOB / CIF)

This reduces production delays and communication loops.

4. Quality Assurance & Communication

Ask your supplier about inspection reports, tolerance levels, and tracking labels. Production feedback ensures hiccup-free progress and early correction.

5. Shipping & After-Sales Support

Confirm shipping mode and documentation (CO, packing list, invoice). Good suppliers will assist logistics tracking and after-sales quality feedback.

Long-term partnerships tend to deliver improved pricing, quicker response, and greater consistency on a variety of SKUs.

12. Conclusion

As we strip away the onion layers of roll label land, one thing is becoming very, very apparent: these small stickers are punching above their weight in the world of packaging and branding. The next time you encounter something wrapped in a beautifully designed roll label, stop for a moment and appreciate the function and artistry that has gone into its creation.

From bringing shelf presence to communicating key information, roll labels are the unsung heroes that follow us through every step of the way. Unlock the power of these adhesive marvels and watch your brand’s presence roll to new heights!

Leave A Comment