Membrane switches, in the scenario of modern electronics, are a fundamental man-machine interface. Membrane switches are applied across the majority of industries due to their flexibility, robustness, and inexpensive cost.

This entire FAQ book discusses the intricacies of tactile membrane switches, their types, advantages, disadvantages, repair, and applications. After reading this book, you will have full understanding of tactile membrane switches and their applications in electronics today.

1. What is a Tactile Membrane Switch?

A tactile membrane switch is an operating device that allows the use of electronic devices with thin, flexible, and durable membrane. Tactile membrane switches are unique compared to conventional mechanical switches in which physical motion either creates or deactivates an electrical connection because they operate based on pressure in a way to switch on a circuit found under the membrane. When triggered, a tactile membrane switch will produce a tactile response—ordinarily a small “click” that will advise the user input has been received.

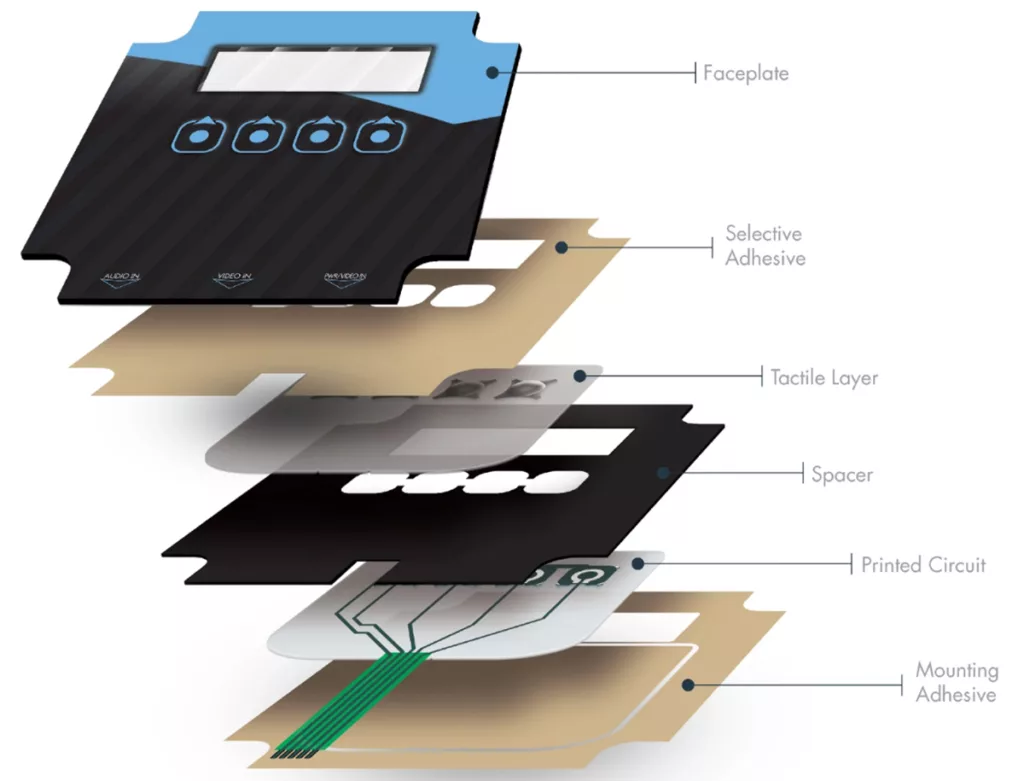

The construction of a tactile membrane switch is typically performed in a number of layers, including a graphic overlay on top, spacer, circuit layer, and backing layer. Tactile sensing is achieved with a domed actuator that will collapse when pressed, making the circuit complete and enabling the desired response.

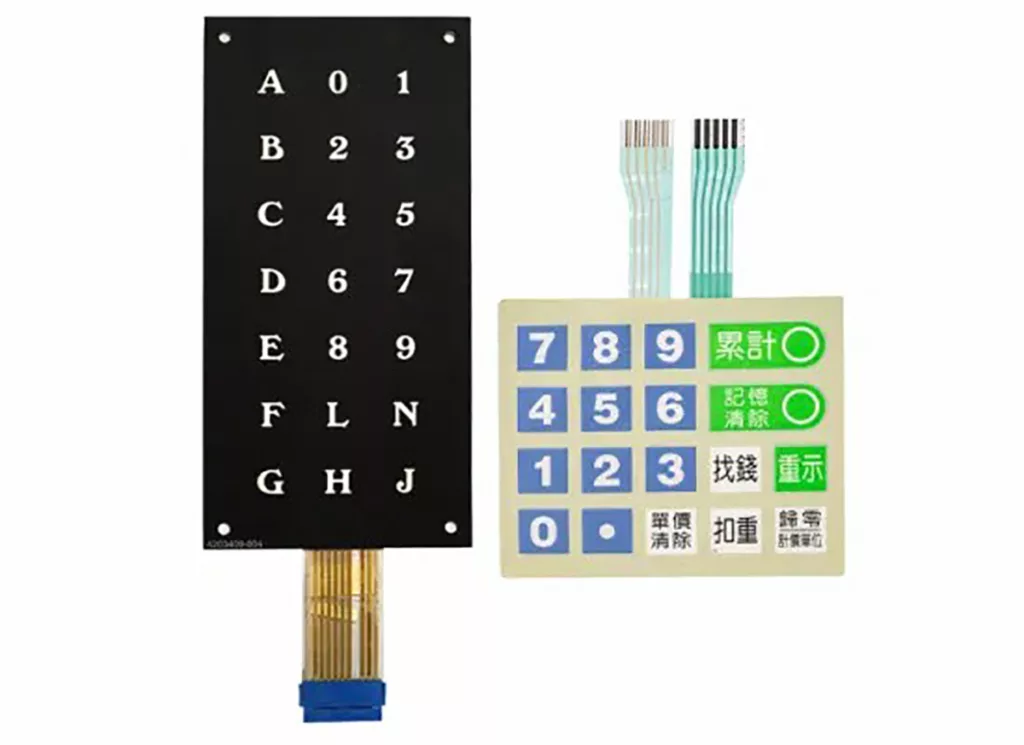

2. Types of Tactile Membrane Switches

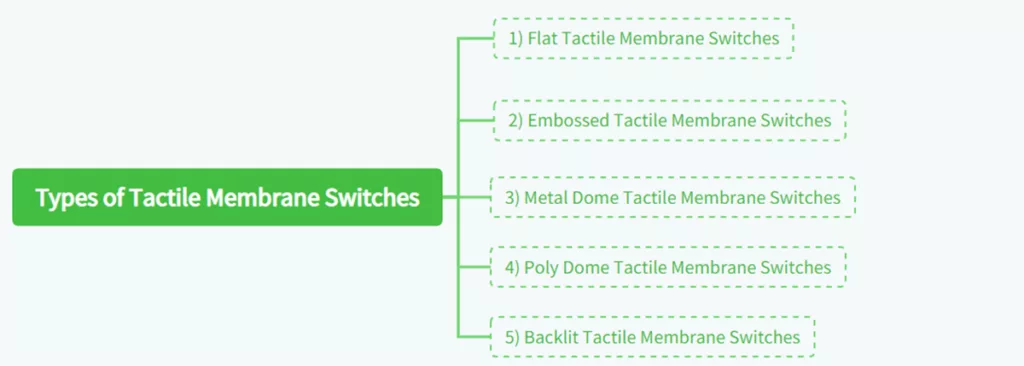

Tactile membrane switches come in various forms, with each intended to meet some application requirement. Familiarity with the forms can guide you in choosing the most appropriate switch to apply to your system or device.

1) Flat Tactile Membrane Switches

Flat tactile membrane switches are the simplest form of these switches. They consist of a flat surface with no raised keys or domes. Even though they also provide tactile feedback, it is generally less substantial than other forms. They are commonly used where space is limited and a low-profile design is required.

2) Embossed Tactile Membrane Switches

Embossed tactile membrane switches feature raised keys or symbols on the surface of the switch. The embossing increases the tactile feedback and makes identification and depressing of the buttons easy for users. The form is applied in the majority of devices where the user interaction is recurrent, such as consumer electronics and medical devices.

3) Metal Dome Tactile Membrane Switches

In metal dome tactile membrane switches, a metal dome under the graphic overlay collapses in upon being pressed to form the circuit and provide a clean tactile “snap.” Metal dome switches are renowned for providing more tactile feedback and endurance and are applied in heavy-use applications such as industrial control panels.

4) Poly Dome Tactile Membrane Switches

Polynome tactile membrane switches use a polyester dome instead of a metal one. While the tactile feedback is less pronounced than in metal dome switches, poly dome switches are more cost-effective and can be used in applications where budget constraints are a priority.

5) Backlit Tactile Membrane Switches

Tactile membrane backlit switches have the light-emitting technology, such as LEDs or fiber optic, to provide light for keys. It has special use where there is little lighting, or where it is very necessary to view the keys, such as in the aviation and automobile sectors.

3. Tactile Membrane Switch Key Material Selection

With tactile membrane switches, the material choice is everything, how it feels under the fingertip, how long it lasts, and how it can handle abusive environments. Every layer has its own function: some provide structure, some transmit signals, and some create the satisfying “click.”

Let’s take a closer look at the key materials that make a tactile membrane switch come alive.

1) Overlay / Graphic Layer Materials

(PET, PC, Plastic Films, Surface Coatings)

The overlay, or graphic layer, is what the user actually touches, it’s the face of the switch. Because of that, it needs to be both beautiful and durable.

PET (Polyester) is the material of choice for most industrial membrane switches. It’s tough, resilient, and heat- and chemical-resistant. PET overlays are resistant to millions of cycles without discoloring or cracking, which is why they’re such a great choice for medical, industrial, and outdoor use.

PC (Polycarbonate) is ever so slightly softer and prints beautifully and is great for consumer products or colorful icon control panels. The drawback is that it scratches more easily and doesn’t take harsh solvents at all.

Hybrid Laminates combine the strengths of both, a PC top layer for print quality and a PET base for durability. Surface Coatings are the finishing touch. UV coatings prevent sun damage, matte finishes cut down on glare, and anti-bacterial or anti-fingerprint coatings make the switch easier to clean and safer to use.

Textures and embossing have a strong impact also. Embossed keys help fingers find their way without looking, while a fine matte texture can turn a simple surface into something elegant and professional.

Tip: The overlay should be thin enough to allow tactile feedback, yet strong enough to protect the dome underneath — usually around 0.125–0.25 mm thick.

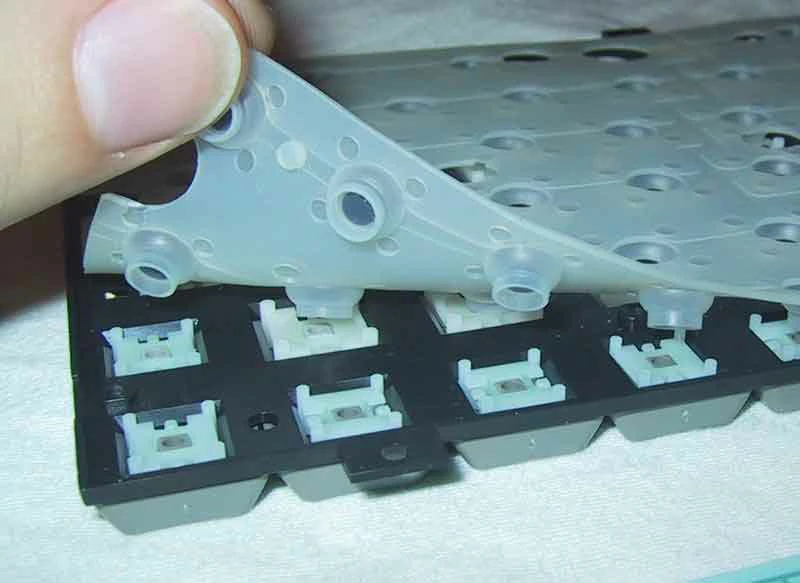

2) Dome Structure Materials

(Metal, Polymer, Conductive Coatings)

The dome is the heart of the tactile membrane switch, it’s what gives that crisp, satisfying “click” when pressed.

Metal Domes, typically made of stainless steel, deliver the most distinct tactile feel. They spring back precisely, can last over a million presses, and offer reliable electrical contact. A thin gold or nickel plating can further improve corrosion resistance.

Polymer Domes (or “poly domes”) use flexible films such as polyester or polyimide. They’re lightweight and give a softer touch, often used when space is limited or when a quieter click is desired. Conductive Coatings like carbon or silver may be used to cover domes in order to provide good electrical contact and prevent oxidation over the long term.

Size, shape, and actuation force of the dome all affect the user experience. More actuation force or a larger dome yields a firm, industrial feel; smaller domes give a lighter, faster touch.

Tipping these factors against the flex of the overlay is key to achieving that perfect tactile feedback.

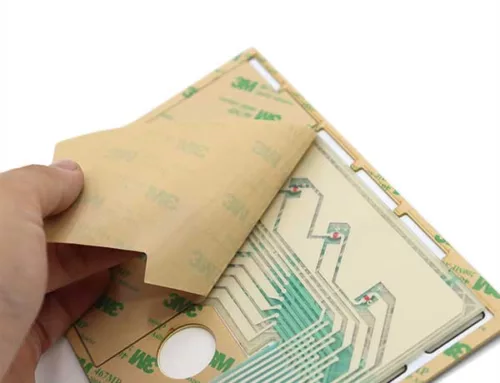

3) Spacer and Adhesive Layers

If the dome is the heart, the spacer and adhesive layers are the skeleton that keeps the whole shebang together. They create the air gap in which the dome can move, and glue the layers together into one solid, reliable shape.

Spacer Films may also be polyester or polyimide, chosen for stability and precise thickness. They define how far the dome can travel when pressed, usually around 0.05–0.2 mm. Adhesive Layers are just as vital. Pressure-sensitive adhesives (PSAs) of high performance, like those offered by 3M, preserve layer alignment against temperature variations and mechanical stress.

In harsh environments, the wrong adhesive can cause delamination or water penetration, small problems that cause enormous failure over time. That’s why professional switch makers always consider temperature, humidity, and chemical exposure before choosing the bonding system.

When laminating, make sure no air bubble or wrinkles are created between sheets. Even a small flaw can change the feel of a button or how long it lasts.

4) Printed Circuit and Conductive Ink Materials

At the heart of every tactile switch is the printed circuit layer, the hidden web that translates touch into electricity. The foundation of the circuit is usually PET film, which is cheap and flexible. For high-heat or high-performance applications, polyimide (PI) substrates take over from PET.

Conductive inks bring the circuit to life. Silver-filled inks are most common because they conduct electricity efficiently and print easily. Some designs add a carbon top layer on contact points to reduce wear and prevent silver migration.

Dielectric Inks separate the traces from each other, preventing short circuits, since protective coatings shield the printed layer from moisture and abrasions. Proper curing is important, under-cured inks might crack or degrade conductivity over the long term. A well-made circuit layer ensures every press is registered accurately, even after hundreds of thousands of cycles.

| Layer | Common Materials | Main Role | Key Advantage |

| Overlay | PET / PC | User interface, protection | Durable, printable, visually appealing |

| Dome | Stainless Steel / Polymer | Tactile feedback | Distinct click, long life |

| Spacer / Adhesive | PET + PSA | Layer bonding, air gap | Stable, precise alignment |

| Circuit | PET + Silver Ink | Signal transmission | High conductivity, flexible |

Each individual layer has its own purpose, but overall, they create something more, a sensitive, consistent, and durable interface that users can trust to work every day.

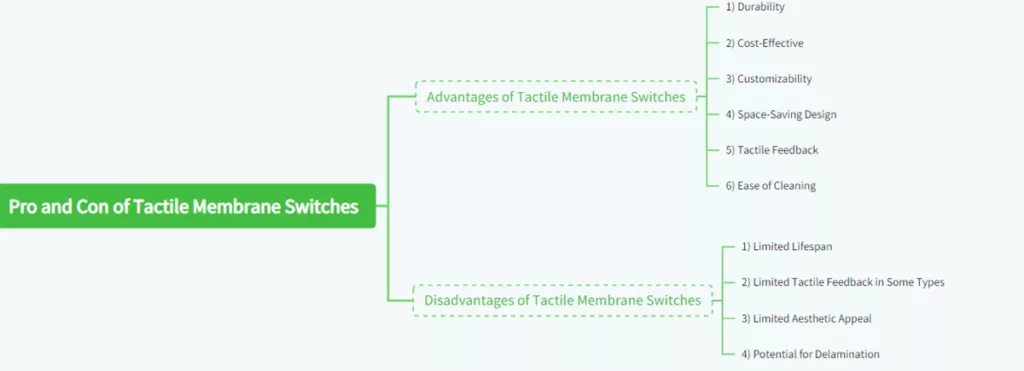

4. Tactile Membrane Switch Benefits

Tactile membrane switches possess a range of advantages that make them widely utilized in all fields of industry. Some of the most critical benefits are listed below:

1) Durability

Reliability is perhaps one of the best aspects of tactile membrane switches. The switches are built with capabilities to resist hostile environmental factors, i.e., chemicals, moisture, dust, etc. Sealed structure prevents contaminants entering inside the switch, thus ensuring the switch becomes long-lasting.

2) Cost-Effective

As opposed to mechanical switches, tactile membrane switches are less expensive to manufacture, especially in volume. They are easy to produce and the use of less expensive materials by them reduces the cost of production by half, hence making them more cost-effective to manufacturers.

3) Customizability

Tactile membrane switches are also designed to meet the unique specifications of a one-of-a-kind device or system. The graphic overlay is printable according to user specifications with logos, symbols, and color, thereby simple to customize. The tactile sensation is also controlled by selecting different dome sizes and material.

4) Space-Saving Design

Since they are built in a thin, lightweight manner, tactile membrane switches are ideal to use where space is an issue. They can be installed into small devices without adding volume too much, and therefore they’re a very appealing option for electronics today.

5) Tactile Feedback

The haptic output of such switches enhances the user experience by mechanical indication of having pressed a button. Such indications are particularly important in applications in which accuracy and precision are first-order considerations, such as for medical devices or industrial control.

6) Easy to Clean

The tactile membrane switch surface is smooth and sealed and easy to clean and sanitize. This is especially crucial in healthcare and food processing settings, where cleanliness is of utmost importance.

5. Tactile Membrane Switch Disadvantages

Tactile membrane switches are not without their drawbacks, even with all the benefits. Some of the potential drawbacks are enumerated below:

1) Limited Lifespan

While durable, tactile membrane switches may not be as durable as mechanical switches, especially in heavy use. The domes utilized within the switch may break down over time, compromising the tactile feedback and leading to eventual failure.

2) Limited Tactile Feedback in Some Types

Although metal dome switches have excellent tactile feedback, some other switches, such as poly dome switches, may provide less intense feedback. This could be a disadvantage in areas where tactile confirmation must be intense.

3) Limited Aesthetic Appeal

While the graphic overlay can be replaced, the tactile membrane switch design is not necessarily so pretty compared to some interfaces such as touchscreens or mechanical keyboards.

4) Potential for Delamination

Over time, layers of a tactile membrane switch can begin delaminating, i.e., become separated. That would lead to reduced function and would necessitate that the switch be replaced.

6. Tactile Membrane Switches Quality Control and Reliability Testing

A tactile membrane switch may seem simple on the surface, but inside it is all about precision and consistency. Quality assurance checks that every layer performs as designed, and reliability testing checks that performance will last for years of use. The following methods are typically used to provide consistent quality from prototype through production in volumes.

1) Life Cycle Testing

The first step in reliability verification is life cycle testing, sometimes called actuation testing. This test indicates how many times a switch is operated before it begins showing signs of failure.

- Test Setup: Mechanical actuator repeatedly presses each key under controlled force and speed.

- Standard Requirements: Industrial or medical device applications have a goal of more than one million actuations with no detectable change in tactile.

- Points of Evaluation: Actuation force, feedback, and electrical response are monitored by engineers throughout the test. Whether the tactile feeling and signal remain consistent, the design is ready to be produced in the long run.

Tip: PET overlays combined with stainless steel domes usually show the best durability in repeated cycle testing.

2) Contact Resistance Testing

All tactile switches use solid electrical contact. Contact resistance testing confirms electrical resistance at the moment when the circuit is closed and current flows unobstructed.

- Measurement Standard: Resistance should ideally be less than 100 ohms, depending on design.

- Procedure: The switch is operated and resistance is measured with a digital multimeter or precision probe.

- Significance: A rise in resistance can indicate contamination, cracking of conductive ink, or shallow dome contact.

A reliable resistance value proves that there is effective process control of the printing and lamination.

3) Environmental Testing

Tactile membrane switches are generally employed in severe environments. Environmental testing simulates real-world environmental exposures such as temperature, humidity, vibration, or chemicals.

- Temperature and Humidity Cycling: The switch is exposed in a chamber that cycles from high to low temperature and humidity to test expansion, contraction, and moisture absorption.

- Salt Spray Testing: Used for marine or exterior application to verify corrosion resistance.

- Chemical Resistance: Cleaning agents, alcohol, or oils are used to coat the surface for testing the overlay and adhesives.

- Vibration and Shock Testing: Specifically for use in the automotive or aerospace industry, it verifies the switch can withstand motion without layer disconnection or circuit failure.

The switch is then retested for feel, appearance, and electrical stability upon completion of testing.

4) Adhesion and Delamination Testing

Strong bonding between layers ensures long-term reliability. Adhesion testing verifies that overlays, spacers, adhesives, and circuit layers remain firmly attached.

- Peel Test: The tensile tester measures the force required to pull apart one layer from another at a given angle.

- Visual Inspection: Engineers inspect visually for bubbles, edge lift, or entrapped moisture that can lead to premature failure.

- Aging Test: Samples are exposed to hot and humid conditions to observe any long-term degradation of adhesive strength.

Proper bonding prevents delamination, maintains tactile accuracy, and protects internal circuitry from dust or moisture.

5) Consistency and Tactile Feel Testing

The tactile “click” defines user experience. Even with perfect electrical function, an uneven feel can make a product seem unreliable. Consistency testing ensures each key produces the same actuation force and travel distance.

- Force Curve Measurement: Specialized testers record the pressing and releasing curve of the dome to evaluate mechanical uniformity.

- Acceptable Range: A deviation of less than ten percent between samples is generally acceptable for high-end switches.

- Human Feedback Test: Experienced evaluators press keys to confirm that the tactile response feels balanced and comfortable.

Combining data-driven testing with user perception ensures every switch delivers the same crisp and satisfying touch.

7. Troubleshooting of Tactile Membrane Switches

Like any other electrical component, tactile membrane switches can also fail with time. Some of the most frequent issues and their resolutions are explained below:

1) Non-Responsive Keys

If none of the switches’ keys respond, there could be a broken dome or a broken circuit behind the issue. In such a case, the switch can be opened and checked for breaks. If the dome is cracked, it needs to be replaced.

2) Reduced Tactile Feedback

If the tactile feedback has diminished, the domes within the switch may be worn out. Replacing the domes or the entire switch may be necessary to restore proper functionality.

3) Intermittent Functionality

Intermittent operation is due to poor contact between switch layers. This type of flaw can easily be overcome by ensuring that layers are properly aligned in sequence and are free from or not contaminated with any particles.

4) Delamination

If delamination of switch layers is occurring, then the switch would need to be replaced. Delamination can also occur due to extended exposure to high temperature, moisture, or chemicals and hence it should be ensured that the switch is operated in good conditions.

8. Applications of Tactile Membrane Switches

Membrane tactile switches are utilized in all types of industries and applications due to the fact that they are resistant and durable. Some of the widely used applications include:

1) Medical Devices

In the medical sector, tactile membrane switches are applied on equipment like diagnostic equipment, patient monitoring equipment, and portable equipment. Since they possess a sealed design, they are simple to clean and disinfect, making them essential in the medical sector.

2) Consumer Electronics

From remote controls to microwaves, tactile membrane switches can be found everywhere in consumer electronics. They are inexpensive and can be designed as per requirement, making them the best option for mass-manufactured devices.

3) Industrial Control Panels

In industrial settings, tactile membrane switches have uses on machines and equipment control panels. They can be used under harsh conditions and are robust and thus suitable for factory, warehouse, and other harsh environment application.

4) Aerospace and Automotive

Tactile membrane switches are utilized by the automotive and aviation sectors in dashboards, control panels, and interfaces. Due to their resilience at temperature and vibration and low weight, they are best fit for use in such areas.

5) Home Appliances

Tactile membrane switches find application in all home appliances, such as ovens, dish washers, and washing machines, as their control devices. They are apt for home appliances since they are convenient and durable.

9. Case Study: How a Specific Device Selects a Tactile Membrane Switch?

To more readily visualize how theory is translated into practice, let’s look at a practical example. Think about a mid-sized industrial control manufacturer producing a new handheld diagnostic product. This product needs a front control panel that is thin, durable, and able to provide clear tactile feedback to gloved operators.

Step 1: Define Application Requirements

The most critical requirements are decided by the design team first. The switch must be compact, water-resistant, and easy to clean, with positive tactile feedback even after repeated use. Also, since the instrument will be used in both factory and outdoor environments, the switch face must be impervious to oil, dust, and exposure to UV.

After consideration, the team decides that a tactile membrane switch is a perfect option as it features a sealed surface in addition to actuation feedback that is customizable.

Step 2: Compare Dome Structures

Two dome options are considered:

- Poly Dome for a soft, quiet touch suitable for light operation.

- Metal Dome for a crisp, audible click and stronger tactile response.

Testing shows that operators prefer the sharp feedback of a stainless steel dome because it confirms activation through both sound and feel. The design adopts a metal dome array rated for one million cycles to ensure long-term reliability.

Step 3: Select Overlay and Adhesive Materials

The surface layer is PET film with a matte UV coating, which is chosen because of its scratch resistance and anti-glare. This not only improves the viewability under high light levels but also resists chemicals typically utilized for cleaning.

For bonding, 3M 467 adhesive is applied to secure the overlay, spacer, and circuit layers. This adhesive maintains excellent strength under temperature changes and humidity, preventing layer separation.

Step 4: Determine Electrical and Circuit Design

The printed circuit layer is designed on PET film with silver conductive ink for fast response and low resistance. A carbon top layer is added at contact points to extend service life and prevent oxidation. To allow for LED indicators, additional transparent windows are included in the overlay, directly above the dome locations.

Step 5: Conduct Reliability and Usability Tests

Before mass-producing the part, the prototype undergoes some significant tests:

Life cycle test: over one million actuations with no tactile degradation.

Contact resistance test: under 100 ohms throughout the test.

Environmental simulation: 60°C, 95% humidity, no delamination or discoloration.

Tactile consistency check: actuation force variation under ten percent between keys.

User testing confirms that operators can easily distinguish every key by feel and get instant confirmation on depression.

Step 6: Final Outcome and Lessons

The chosen tactile membrane switch meets all performance and durability targets in a thin profile and clean surface. Compared with a mechanical keypad, the final design reduced overall thickness by 35 percent and assembly cost by 20 percent.

This example illustrates the importance of matching design priorities with those of the real world. By making trade-offs in tactile preference, environmental durability, and manufacturability, engineers can create control panels that feel professional, last longer, and perform better under stress.

10. Choosing the Right Tactile Membrane Switch Manufacturer for the Future

As tactile membrane switch technology continues to evolve, choosing the right manufacturing partner has become more than an exercise in comparing lead times or costs. A good manufacturer not only should be capable of meeting your current requirements but also should be aware of where the industry is headed and be ready to help you transition. Some of the key areas to question while selecting a long-term, future-ready membrane switch supplier are given below.

1. Technical Expertise and Material Knowledge

A quality manufacturer must possess a quality understanding of materials, dome constructions, and conductive systems. They must be able to define metal compared to polymer domes, suggest adhesive systems for heat or humidity, and comprehend the effect of PET, PC, and coatings on performance.

Ask potential partners how they control layer lamination, alignment, and embossing, and whether they perform life cycle and contact resistance testing in-house. Manufacturers that can guide you through these details are more likely to ensure long-term consistent quality.

2. Advanced Production Capabilities

Membrane switch manufacturing today is no longer just a print-and-cut affair. Leading manufacturers now employ laser cutting, UV printing, auto-alignment, and dome placement systems to achieve higher precision and lower defect rates. Some even use AOI (Automatic Optical Inspection) for printing circuits and robot lamination to eliminate human variation.

When evaluating a supplier, look for signs of cutting-edge production lines, cleanroom assembly, and certifications such as ISO 9001 or ISO 13485 if you are in the medical field. It is sophisticated process control that will set a high-quality switch apart from a standard one.

3. Experience with Your Industry

Different applications have different demands. Medical devices need to be sterilization resistant, auto parts must resist vibration and temperature fluctuation, and commercial products require attractive visual design.

Choose a manufacturer with project experience in your industry, not just general membrane switch production. Ask for past case studies, product photos, or references. A supplier that’s already familiar with your industry will require less start-up time and perform better sooner.

4. Customization and Design Support

Progressive manufacturers don’t merely manufacture – they’re design partners. They might be able to assist with circuit layout, dome selection, LED placement, and backlighting integration, and deliver prototypes that enable you to evaluate tactile feel before full production.

When a supplier can provide rapid prototyping, digital design previews, and material samples, it’s an indication that they value engineering collaboration and are established for customer-driven, flexible production.

5. Testing, Quality Control, and Reliability Assurance

Reliability is paramount in a competitive market. Your manufacturer of choice should perform regular environmental testing like temperature cycling, humidity exposure, and peel strength testing. They should also maintain in-house record-keeping like process control charts and traceable batch records for repeatability.

Don’t hesitate to ask about their test fixtures or how often they calibrate. Leading suppliers will welcome transparency because they know that reliability builds reputation.

6. Innovation and Sustainability Awareness

The trend in technology is for thinner, lighter, and lower-power membrane switches with improved environmental performance. Manufacturers who invest in eco-friendly materials, recyclable substrates, and low-VOC inks will be better prepared for tomorrow’s sustainability requirements.

Innovative vendors also experiment with hybrid designs combining tactile feedback with capacitive or touch-sensor technology for ease of integration with user interfaces of tomorrow.

7. Long-Term Partnership and Communication

Finally, an ideal supplier is one that communicates effectively and is responsive throughout your project. They should be prompt to provide feedback on design changes, provide realistic lead times, and be consistent in quality as well as price.

Look for a partner who views your project as a shared goal rather than a one-off transaction. A good working relationship will allow you to make adjustments to new specifications, adopt new materials, and keep your products in harmony with evolving market trends.

11. Conclusion

Membrane switches are a common component of contemporary electronics, and they represent a cheap, resilient, and versatile solution to user interface. Sure, maybe they might have several disadvantages, but their advantages completely overshadow the detractions, and that is only one of many reasons why so many industries adore them so.

Armed with this knowledge of tactile membrane switch types, advantages, disadvantages, and how to repair them, you can make informed decisions when it comes to incorporating them into your designs. With applications as wide-ranging as they are and with their established record of reliability, tactile membrane switches are sure to remain an electronics staple for decades to come.

Leave A Comment