In this high-tech, fast-paced era, membrane switches are a ubiquitous component of electronic equipment. In this in-depth FAQ article, we will walk you through the basics of waterproof membrane switches, from types to advantages and disadvantages to troubleshooting methods and uses. Reading this article, you will be thoroughly knowledgeable about waterproof membrane switches and their applicability in modern electronics.

1. What is a Waterproof Membrane Switch?

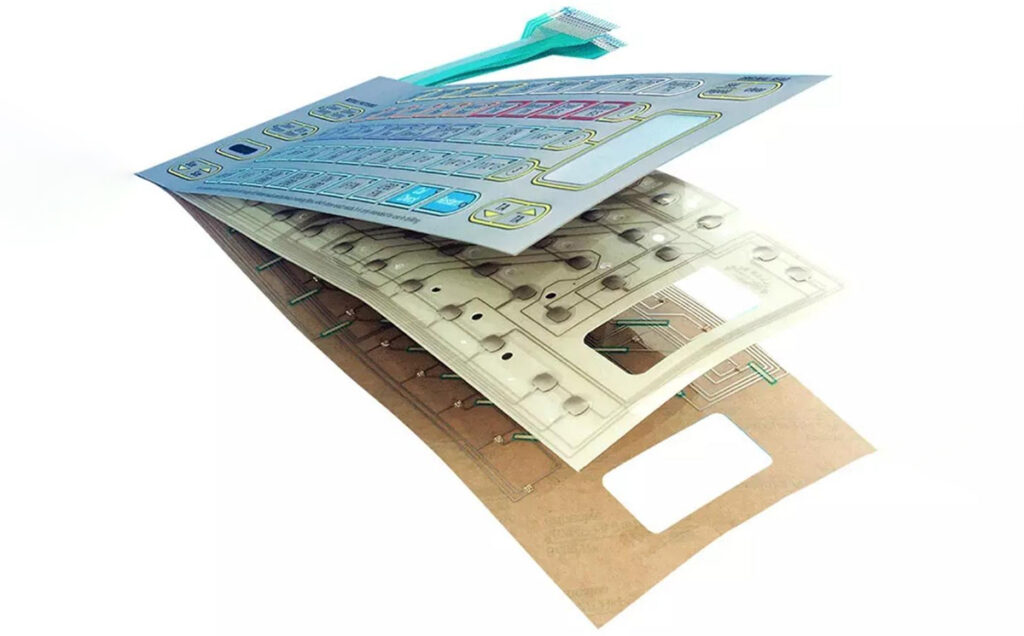

A waterproof membrane switch is a human-machine interface that is specially applied in applications where there is water exposure, moisture, or other liquids. Membrane switches are liquid-damage-sensitive, but waterproof membrane switches are specially made to resist water and function even in wet or damp conditions.

Waterproof membrane switch generally consists of a combination of a number of layers, including graphic overlay, spacer, circuit layer, and backing layer. Switch type changes depending on the use of special sealing technology, i.e., adhesive gaskets, perimeter seals, or conformal coatings, in order to seal the switch to be waterproof.Allows the switch to function in full even submerged in water or other liquids.

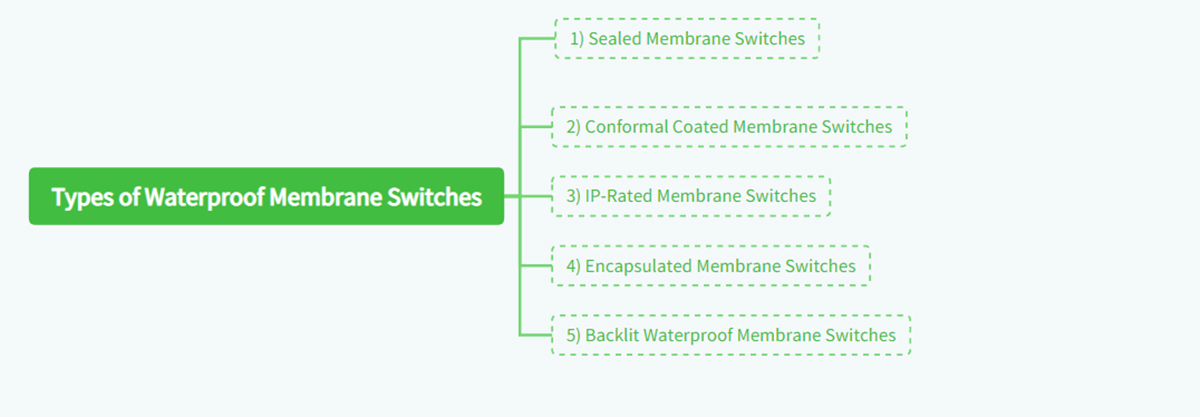

2. Waterproof Membrane Switch Types

There are several types of waterproof membrane switches, and each will require a different application. Being aware of the differences will allow you to find the optimal switch for your particular application.

1) Sealed Membrane Switches

Sealed membrane switches are the most common type of waterproof membrane switch. They possess adhesive gaskets or edge seals to create a watertight seal around the switch layers. Sealing keeps water from the switch and does not allow it to enter the switch and damage the internal wiring within it. Sealed membrane switches are usually used where the product might be exposed to splashing, rain, or humidity.

2) Conformal Coated Membrane Switches

In conformal-coated membrane switches, there is a coating placed over the circuit layer in order to protect it from contaminants and moisture. Conformal coating is normally of materials comprising silicone, polyurethane, or acrylic and provides water as well as environmental resistance with extremely high levels of excellence. The subject switches are suggested in applications in which the switch has to be directly inserted into water or other liquid form.

3) IP-Rated Membrane Switches

IP-rated membrane switches have been engineered to meet certain **Ingress Protection (IP) ratings**.

For example, ratings against solid foreign objects and water. A good example is an IP67-rated membrane switch, which shall be dust-tight and shall withstand submersion in water for a fixed time period up to a certain depth.

It is particularly useful in conditions of low light or outdoor applications where visibility is a requirement. Backlighting is fully integrated into waterproofing such that the switch is sealed and shielded from water. Waterproof IP-rated membrane switches are utilized non-stop in sea and outdoor industrial control panel instrumentation.

4) Encapsulated Membrane Switches

Encapsulated membrane switches are entirely sealed in a cover that incorporates a secondary amount of protection for water, dust, and other external hazards. Encapsulation allows the switch to be operational with very harsh environments and is the best choice in extreme environments such as military or aviation.

5) Backlit Waterproof Membrane Switches

Waterproof membrane switches with the use of backlighting components such as LEDs or fiber optics illuminate the keys. It is particularly useful in conditions of low light or outdoor applications where visibility is a requirement. Backlighting is fully integrated into waterproofing such that the switch is sealed and shielded from water.

3. Waterproof Membrane Switch Materials and Process Essentials

The performance of the waterproof membrane switch largely relies on the quality and compatibility of its materials. Each layer, from the surface film to the adhesive and backplate, plays a critical role in maintaining waterproof integrity, durability, and tactility. Choosing the right combination ensures reliability and manufacturability.

1) Common Material Selection

The following is an introduction to the material selection for each layer of the structure.

1. Graphic Overlay Materials

The graphic overlay is the outermost surface of the membrane switch and serves as user interface and primary protective cover. The most widely used materials are polycarbonate (PC) and polyester (PET).

Polyester (PET): It is known for good flexibility, chemical resistance, and durability. Polyester accommodates repetitive actuation (over 1 million cycles) and remains colorfast under humidity or cleaning solutions. PET is the preferred material for use in medical, industrial, and outdoor applications.

Polycarbonate (PC): Offers good clarity, printability, and impact resistance. Has smooth or textured finish and is appropriate where appearance is more valuable than extreme durability. But will yellow under prolonged UV exposure unless coated.

In some designs, overlays may be made stronger with UV-curable coatings or hard coats to increase abrasion and chemical resistance, and matte textures can reduce glare and increase readability.

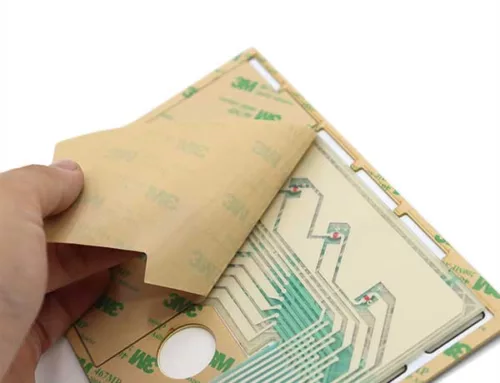

2. Adhesive Layers

The adhesive layer holds the overlay, spacer, and circuit layers together. For wet designs, the adhesive should be moisture-resistant, dimensionally stable, and compatible with the substrate and circuit inks.

- Acrylic adhesives are widely used as they offer high bonding strength and good thermal and humidity resistance.

- Silicone adhesives are applicable for high-temperature or flexible applications, providing superior sealing.

- Pressure-sensitive adhesives (PSA) such as 3M 467MP or 3M 468MP are often employed in high-end membrane switches because of their clean bonding and durability.

Thickening of the adhesive typically falls within the range of 0.05 mm to 0.2 mm and depends on the design. To achieve enhanced waterproof capability, adhesive edges can be extended beyond the perimeter of the switch to form a complete waterproof seal.

3. Sealing and Waterproofing Materials

Sealing components protect internal layers from water, dust, and other contaminants. Waterproof membrane switches use two-part structural sealing in addition to material-based sealing.

Common sealing methods include:

Silicone gaskets or O-rings: Provide flexible compression seals along the switch border or around the connector area.

Epoxy or urethane encapsulation: Forms an integral solid shield on electronic interfaces or connectors.

Overmolded edges: Used in fully integrated assemblies where switch is overmolded with rubber or plastic housing.

Waterproof coatings: Hydrophobic film or conformal coating applied over the circuit layer to avoid moisture diffusion.

Materials have to be selected so that flexibility, adhesion, and temperature resistance are optimized. For example, silicone is more flexible and weather resistant, and epoxy is harder and chemically resistant.

4. Circuit Layer and Conductive Inks

The circuit layer is usually printed on a polyester substrate in conductive inks. Silver-based inks are most common since they exhibit low resistance and high adhesion. For water-resistant or high-reliability applications, carbon or graphite layers are sometimes deposited to inhibit oxidation.

Key considerations include:

Ink curing temperature (must be compatible with film substrate)

Trace width and spacing to prevent short circuits under humidity

Protective dielectric layers to insulate circuits from moisture penetration

5. Backplate and Support Layer

The backplate provides mechanical support and mounting. Aluminum, stainless steel, polycarbonate, or fiberglass-reinforced epoxy (FR-4) are typical materials.

Aluminum offers high rigidity and heat dissipation and is suited for application on industrial machinery.

FR-4 offers electrical insulation and structural stability for complex assemblies.

Composite or plastic backers are used in low-duty devices where cost and flexibility are the priorities.

For fully sealed assemblies, the backplate can incorporate the gasket interface so that the entire switch structure provides a consistent compression and waterproofing effect.

2) Integration Considerations

In combining these materials, they must be thermally compatible, chemically bonded, and dimensionally stable. Moisture entry or delamination can occur from combining materials in a manner that is incompatible. Most companies perform peel strength testing, humidity aging testing, and thermal cycling testing to confirm long-term adhesion and sealing performance.

An ideal combination material not only enhances waterproof reliability but also enhances tactile feel, backlight clarity, and manufacturing efficiency, ensuring that the switch performs reliably throughout its lifecycle.

4. How Do You Design Waterproof Membrane Switches?-Rules and Standards

Designing a waterproof membrane switch requires careful integration of structural design, material selection, and sealing methods. The goal is to ensure stable electrical performance with full protection against water, dust, and environmental stress. The above listed design rules and standards allow engineers to provide consistent quality and long-term reliability.

1. Dimensional Accuracy and Assembly Tolerances

Precise dimensioning is fundamental to waterproof reliability. Each layer including overlay, spacer, circuit, and backplate must align accurately to prevent internal stress or gaps. The general tolerance for alignment between printed layers should be within ±0.15 mm, while the outer contour tolerance should remain within ±0.25 mm.

For mechanical mounting parts such as LEDs or connectors, maintain sufficient clearance to account for manufacturing tolerance. Avoid sharp radii of internal corners because they concentrate stress and create delamination. Rounded corners of a minimum of 1 mm increase strength and sealing uniformity.

2. Button Layout, Key Travel, and Tactile Response

In waterproof designs, tactile performance must be achieved without compromising sealing. Button spacing should be at least 6 mm for consistent actuation without unwanted presses.

For metal dome tactile switches, key travel is typically between 0.2 and 0.6 mm based on the dome type and the overlay thickness. The embossed areas of the overlay must have smooth curves with a minimum corner radius of 0.5 mm to prevent print stress or cracking.

If tactile feedback is not required, a planar non-tactile design can be used. This design makes sealing easier but requires obvious visual or auditory feedback such as LEDs or buzzers for user return.

3. Waterproof Edge and Frame Design

Edge sealing is the most critical aspect of waterproof performance. Ensure all layer edges are co-registered and adhesives completely cover the perimeter. Water entry is prevented by overlapping adhesive borders of 1.5 to 2 mm beyond the circuit area.

For high IP ratings such as IP67 and above, use double-layer sealing, for example combining an inner adhesive seal with an outer silicone gasket. If the switch is mounted into a housing, the frame compression area must be even and flat to provide even pressure. Recommended compression deformation for gaskets is 10 to 25 percent of thickness to provide maximum sealing without permanent deformation.

4. Light Transmission and Backlight Design

If the design includes backlighting, select transparent or semi-transparent overlay materials with consistent optical density. Do not print conductive traces or white opaque inks directly over transparent windows. Best transmittance for areas that are uniformly illuminated is 20 to 40 percent depending on LED brightness.

Place LEDs between the sealing boundary to reduce heat stress to adhesives. Diffusion films or light guides can help balance illumination and minimize hotspots. Always verify that lighted regions maintain waterproof integrity through adhesive reinforcement or transparent sealing films.

5. Venting and Pressure Equalization

Internal air pressure, when the membrane switch is housed in sealed enclosures, may fluctuate with temperature changes. To prevent delamination or false actuation, integrate a microporous vent that allows air exchange while blocking liquid water.

PTFE vent membranes are commonly used for this purpose. They equalize pressure without compromising waterproof performance, improving both tactile response and structural stability.

6. Test Points and Electrical Connections

Test points should be positioned away from the main sealing area to avoid waterproof layers getting damaged. Use gold-plated or carbon-coated contacts to enhance corrosion resistance. For external connectors, use epoxy sealing, silicone encapsulation, or IP67 or more waterproof connectors. Do not bend flexible circuits across sharp housing edges or around screw locations that can bend insulation.

7. Graphic and Text Design Standards

Graphics printed on flexible circuits must remain legible and serviceable following prolonged exposure to moisture, UV radiation, and cleaning solvent exposure. Apply UV-resistance and solvent-resistance inks, and a clear coat protective film when necessary.

Leave printed legends at least 2 mm away from cutouts or raised areas to prevent warping. To provide good high-contrast visibility, light background with dark print and no color gradient in the vicinity of button regions should be eschewed.

8. Compliance and Testing Standards

Waterproof membrane switches should be designed in accordance with industry and international standards.

- IP Rating (IEC 60529) sets ingress protection classes against solids and liquids.

- ASTM D3359 specifies adhesion testing of coatings and printed surfaces.

- ASTM B117 specifies salt spray testing for resistance to corrosion in marine or outside environments.

- ISO 4892 covers UV aging resistance for overlay materials.

- UL 94 specifies flammability standards for plastic films and substrates.

In addition, manufacturers often implement full functional testing for continuity, resistance, and actuation force before final assembly. Periodic batch testing for waterproof integrity ensures consistent performance across production runs.

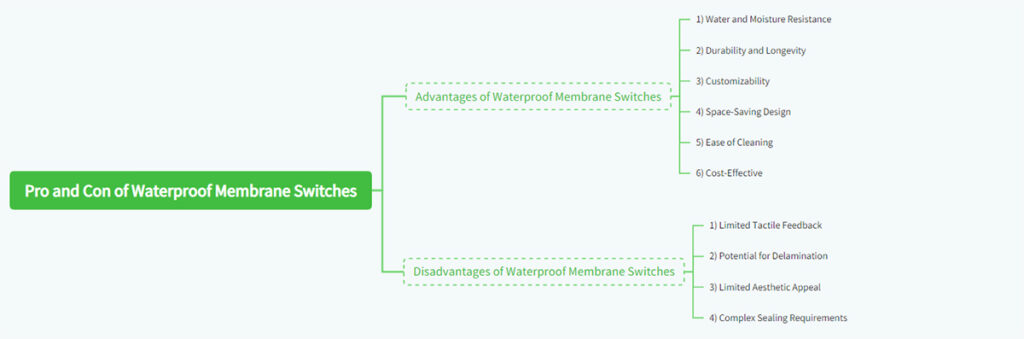

5. Advantages of Waterproof Membrane Switches

Waterproof membrane switches boast several advantages that render them common in a wide range of applications. Some of the key benefits are summarized below:

1) Water and Moisture Resistance

The most apparent benefit of waterproof membrane switches is that it is water-resistant and moisture-free. Waterproof membrane switches are built with the capability to function efficiently even in wet or moist conditions, thus making them suited for use where exposure to liquid is present. From outdoor devices to medical devices, to machinery, waterproof membrane switches offer a promise to their clients that even in bad circumstances, the product will still function.

2) Long Life and Reliability

Waterproof membrane switches are engineered to operate optimally in harsh weather conditions, water submersion, chemicals, dust, and high-low temperatures. Sealed construction and long-life material guarantee that switches can last decades even on hostile applications.

3) Customization

Like in other membrane switches, waterproof designs can also be entirely customized to meet the special needs of a device or system. Graphic overlay can be printed with special colors, symbols, and logos, thereby being fully customized. Sealing, tactile feedback, and backlighting can also be custom-made based on the application demands.

4) Space-Saving Design

Waterproof membrane switches are thin and lightweight, and hence they are ideal for applications where space is limited. They can be installed in devices without occupying much space, hence being the first preference in modern electronics.

5) Ease of Cleaning

Easy cleansing and disinfecting of waterproof membrane switches with a smooth watertight finish is possible. This is most important in food processing, pharmacy, and health care applications where hygiene is the key. Being watertight in design insulates the switch from water, cleaning fluid, and disinfection fluid penetration and thus allows the switch to perform even after numerous cleaning cycles.

6) Cost-Effective

In comparison with other waterproofing technologies, e.g., mechanical seals or mechanical enclosures, membrane waterproof switches are relatively cheap to produce. They have a simple design and raw material cost that is low, making them a cost-effective solution for manufacturers if produced in large quantities.

6. Disadvantages of Waterproof Membrane Switches

Although waterproof membrane switches have a number of benefits, they also suffer from some disadvantages. Some of them include:

1) Poor Tactile Feedback

One of the foremost disadvantages of waterproof membrane switches is that they can yield less satisfactory tactile feedback than mechanical switches. While some waterproof membrane switches contain tactile domes to include the “click” sense, the feedback can be less sharp than that of simple mechanical switches. It is a disadvantage where clear tactile confirmation is required.

2) Delamination risk

As they age, layers of a water-resistant membrane switch can begin to delaminate, a phenomenon known as delamination. Perhaps the result of prolonged exposure to heat, chemicals, or humidity, it will lead to below-average performance or failure of switches. Proper sealing can minimize the chances of delamination, although in some environments, it’s still an opportunity.

3) Limited Aesthetic Appeal

Although the graphic overlay of a waterproof membrane switch may be stylistically designed according to requirement, the overall appearance may not look as good as in some other interfaces, i.e., touchscreens or mechanical keyboards. If aesthetics are a key factor in an application, waterproof membrane switches may not be suitable.

4) Complex Sealing Requirements

To be completely waterproof, it requires precise sealing techniques and materials. Unless sealed, there is water intrusion into the switch and lead to switch failure. The manufacturing process is thus complicated and can be more costly in some cases.

7. How to Choose the Right Waterproof Membrane Switch?

Selecting the correct waterproof membrane switch is a process of balancing technical specifications, environmental conditions, and cost considerations. Because every use has its own operating conditions, i.e., temperature, humidity, outdoor exposure, or level of hygiene, the right choice will deliver long-term reliability and customer satisfaction.

1. Identify the Application Environment

The initial step is to define precisely where and how the membrane switch will be applied. For indoor use such as control panels for medical or lab equipment, a general IP rating of IP54 or IP65 is adequate. In these applications, cleanliness and chemical resistance are more important than protection from harsh weather conditions.

For outdoor or hostile industrial applications, where the switch might be subjected to rain, dust, UV, or high pressure, IP68 or IP67 rated designs are desirable. Such switches will typically employ perimeter sealing using silicone gaskets, waterproof adhesive coats, or molded cases completely preventing water entry.

In seagoing, automotive, or farm equipment, select switches that are capable of withstanding constant moisture, vibration, and temperature changes. In such situations, reinforced sealing materials and flexible adhesives help ensure consistent contact performance.

2. Define Functional and User Requirements

Consider the manner in which the user will interface with the device. Where tactile feedback is essential, for example, in industrial control panels or field instruments, incorporate tactile membrane switches with metal domes or embossed buttons. They possess a good click feel that confirms activation even when gloves are worn.

If the design calls for a modern, smooth surface with no detectable buttons, flat switches that are not tactile or capacitive touch membrane switches can be the best option. They are most suitable for places where more frequent cleaning or sterilizing is necessary, like in medical or food processing machinery.

If visual signals are integrated into the interface, employ switches with embedded LEDs or backlight layers and seal them so that they are evenly lit without compromising on waterproof integrity.

3. Consider Material and Durability Requirements

All the parts of the membrane switch collectively provide the overall performance. Polyester (PET) is an excellent option where chemical resistance and flexibility are needed, for example, while polycarbonate (PC) is more appropriate for higher mechanical strength and print graphics clarity.

Under wet or exterior environments, avoid adhesives absorbing moisture or suffering loss of adhesion from temperature cycling. Use UV-resistant inks and coatings on graphic overlays exposed to sunlight. Where equipment will be solvent cleaned, choose materials resistant to alcohol or disinfectant contact without discoloration or cracking.

4. Match IP Rating and Sealing Method to Conditions

The level of waterproof protection is determined by the sealing method:

IP54–IP65: Adequate for light splashing and exposure to indoor humid environments. Best suited for hospital or laboratory equipment.

IP66–IP67: More tolerant to heavy splashing and brief water immersion. Best suited for outdoor panels and transport equipment.

IP68: Fully submersible, best suited for marine, military, or field-applications devices with continual water exposure.

Always check sealing materials (silicone gaskets, O-rings, epoxy encapsulation) for compatibility with your substrate and operating temperature range.

5. Evaluate Production and Maintenance Factors

Choose a design that fits your production volume and maintenance plan. Switch designs of a modular type are simple to substitute and have minimal downtime. If the equipment is serviced regularly, use adhesive-mounted switches over a sealed molded design, as they are simpler to replace.

If manufacturing involves multiple units or frequent design alterations, standardizing on a singular membrane switch type and specifying only the graphic overlay can save time and money.

6. Balance Performance and Cost

Improved waterproof ratings, premium materials, and backlight capabilities obviously cost more. In budget-oriented environments, determine which of the specifications are absolutely necessary. For example, indoor equipment might not need an IP68 rating, but premium outdoor systems must have it for safety and reliability.

A good practice is collaborating with the maker at the outset of the design phase. They can recommend affordable structures, subject prototypes to simulated environments, and provide honest criticism of what levels of performance are achievable.

In general, choice of the best waterproof membrane switch depends on an understanding of the surroundings, user interface needs, and material behavior under real conditions. An accurately matched design does more than protect against moisture damage; it provides better usability, reduced maintenance, and extended product operating life.

8. Waterproof Membrane Switch Troubleshooting

Like any electronic product, waterproof membrane switches may also malfunction with usage. Some of the issues and their troubleshooting are:

1) Unresponsive Keys

If a switch key or keys are not functioning, the issue could be caused by a damaged circuit or a damaged dome. In either event, the switch would need to be dismantled and examined for damage. If the dome was damaged, then it will need to be replaced. Check also for water entry that could have damaged the internal wiring.

2) Water Ingress

Should water have penetrated the switch, it will render the switch useless. Check switch layer-to-layer seal for continuity. If there is a break in the seal, the switch may have to be replaced or resealed. Drying out the switch and then sealing it up again will, in many cases, put the switch back into service.

3) Reduced Tactile Feedback

If tactile feedback is eliminated, domes in the switch can wear down. Domes, or even the switch itself, might need to be replaced to restore correct function. Also, keep the switch from being subjected to an overabundance of moisture, which will make the tactile response interfere.

4) Delamination

If switch layers do delaminate, the switch would need to be replaced. Delamination is possible with extended exposure to chemicals, heat, or water, so ensure the switch is used in its proper conditions. Regular inspections during preventive maintenance can be used to detect delamination before failure.

9. Waterproof Membrane Switch Applications

Waterproof membrane switches are utilized in a wide range of markets and industries due to their flexural capability as well as hardness. Among some of the most common uses include:

- Medical Devices: Medical equipment such as diagnostic equipment, patient monitoring equipment, and portable medical equipment

- Outdoor Equipment: Marine electronics, weather station equipment, and outdoor control enclosures

- Industrial Control Panels: industrial plants, warehouses, and other abusive environments

- Consumer Electronics: remote controls, cook equipment, and outdoor electronics

- Aerospace and Military Applications

10. How to Find a Reliable Waterproof Membrane Switch Manufacturer?

The choice of the proper manufacturer is one of the most important decisions while designing a waterproof membrane switch. The quality of the manufacturing partner has a direct effect on the product’s performance, reliability, and long-term stability. An experienced and competent supplier not only ensures production accuracy but also allows for optimal design and cost savings.

1. Evaluate Technical Expertise and Experience

Start by verifying the technical and engineering capability of the manufacturer. The good supplier should have a past history of producing waterproof membrane switches to multiple industries such as medical devices, industrial control panels, outdoor equipment, or consumer electronics.

Check whether they can produce switches with various waterproof levels such as IP65, IP67, or IP68. Ask for samples of previous work, especially ones with the same application or working environments. A seasoned manufacturer with real-world project experience can provide professional insights into materials, seal designs, and lifespan.

2. Check Production Equipment and Process Control

High-performance membrane switch manufacturing requires precision cutting, lamination, and printing equipment. Make sure the factory uses automated screen printing presses, clean-room assembly plants, and laser or die-cutting equipment that ensure consistent accuracy and cleanliness.

A professional manufacturer will also stick to standard process control systems, like stringent environmental controls of temperature and humidity during lamination and curing. These controls are required to provide consistent adhesion, prevent contamination, and impart consistent waterproof performance.

3. Review Quality Assurance and Certifications

A good manufacturer should have a documented quality management system, ideally certified under ISO 9001 or ISO 13485 (for components of medical devices).

Inquire about their test processes and what they are able to test for, such as:

- IP waterproof testing

- Adhesion and peel strength testing

- Electrical continuity and actuation force testing

- Aging, salt spray, or temperature-humidity cycle testing

Manufacturer in-house reliability testing can detect defects prior to shipment, resulting in less likelihood of field failure.

4. Assess Material Sourcing and Stability

The quality of a waterproof membrane switch depends upon the stability of overlays, adhesives, and conductive inks. The good manufacturer has to have long-standing relationships with established material suppliers, such as 3M for adhesive coatings or Dupont and Autotype for films and inks.

Request information about where the materials came from and whether they are RoHS and REACH compliant. Consistent sourcing ensures that all production runs are held to identical mechanical and environmental performance requirements.

5. Evaluate Design Support and Customization Capability

A better manufacturer provides design support initially. They can review your drawings, suggest materials for application in your environment, and optimize the circuit layout or seal design.

Ask if they have quick prototyping capabilities. Ability to generate small pilot batches quickly helps with validation of performance before large-scale production. Design assistance and early collaboration often save time and cost in future product development phases.

6. Review Communication and Responsiveness

Successful global projects. Smooth communication is crucial. Evaluate how quickly and accurately the manufacturer replies to technical questions or quotes. Credible suppliers provide clear documents, drawings, and inspection reports.

Whenever possible, speak directly to their engineering staff rather than only sales staff. This matters for technical accuracy and faster resolution of design issues.

7. Request Samples and On-site Evaluation

Before committing to a long-term partnership, always request product samples. Evaluate the tactile feel, sealing quality, graphic printing, and waterproof performance through real-world testing.

If feasible, conduct a factory audit or virtual tour to verify production capacity, cleanliness, and organization. Observing their assembly process provides valuable insight into their reliability and professionalism.

8. Compare Cost Transparency and Delivery Reliability

A trustworthy manufacturer provides a clear and detailed quotation that lists material type, printing method, lamination process, and testing costs. Avoid suppliers who offer unusually low prices without technical explanations, as this may indicate the use of inferior materials or lack of quality control.

On-time delivery is another key factor. Review their typical lead times for prototypes and bulk production. A manufacturer with a stable production schedule and proven supply chain management helps ensure that your project stays on track.

9. Build a Long-Term Partnership

Once you identify a reliable supplier, it is best to establish a long-term partnership. Sharing your standard specifications, test requirements, and quality expectations allows the manufacturer to maintain consistency across multiple orders. Long-term cooperation also encourages technical innovation and cost optimization over time.

11. Conclusion

By knowing this about the replacement types, advantages, disadvantages, and repair of waterproof membrane switches, you will be able to make the right choices regarding the use of them in your work. With their widespread applicability and proven reliability, waterproof membrane switches are sure to remain a fundamental part of the electronics world for a very long time to come.

Leave A Comment