Custom Graphic Overlay from MSTR

At MSTR, we specialize in creating high-performance graphical overlays for a broad spectrum of equipment and device user interfaces. With a capacity to manufacture more than 1,000,000 units per month, we offer scalable solutions that cater to the demands of international industries.

We offer a single-source graphic overlay manufacturing service that encompasses design, high-accuracy printing, adhesive selection, and die-cutting. All to your exact specifications relative to size, material, quantity, design, and packaging. Not only do our overlays offer a functional enhancement for products, but they also add a sleek, high-quality appearance that makes your brand highly noticeable in the market.

With over 20 years of experience, MSTR has been the preferred OEM partner to 300+ customers a year from industries ranging from consumer electronics to automotive, industrial equipment, and medical devices. Global world-class brands such as Lenovo, Huawei, Cisco, T&W, Haier, ZTE, and TCL are included. Rely on us for uncompromising quality and consistency.

If you are looking for a reliable graphic overlay manufacturer, MSTR can take your product to new heights, from design to production manufacturing. Contact us for a tailor-made graphic overlay solution.

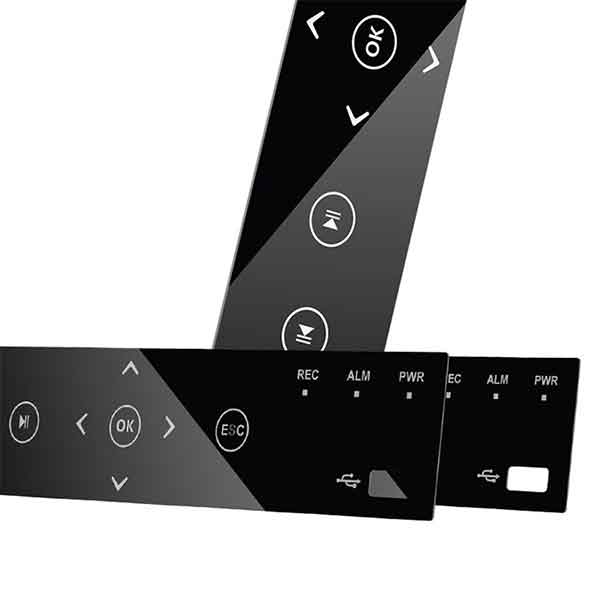

Featured Graphic Overlays

Printed Overlays

MSTR provides printed overlays provide a high-gloss, visually striking surface for electronic and control devices with enhanced color brilliance and graphic definition. We are optimized for both performance and design to ensure they have superior durability with scratch, moisture, and environmental resistance.

We provide high-definition printing of logos, icons, and text that blend with device interfaces with ease. We can provide customized full options, so our printed overlays have a clean, modern look without sacrificing functionality and long-term performance.

Polycarbonate Overlay

MSTR provides polycarbonate graphic overlays that are highly resilient and generally used in control panels, keypads, and machines. Our polycarbonate graphic overlays possess high impact, chemical, and clarity resistance features, and are optimum to utilize in abusive applications.

We can die-cut them to have complex cut-out shapes with clear windows or holes and top with silkscreen printing that’s long-lasting graphics. Pair our products with 3M die-cut adhesive and they possess strong, reliable adhesion on all types of surfaces without involving the cost of tooling.

IML(In Molding Label)

MSTR’s IML features a 2H-4H hardness-hardened PET surface with excellent scratch and wear resistance. Our printing layer between the protective film and injection molding layer can produce a rich, durable color that will not fade.

Precision printing, molding, die-cutting, and back injection molding are merged in this process to create an error-free, strong, and high-quality finish. Our IML highly suited for electronic interfaces, auto panels, and industrial applications.

Steps to Custom Graphic Overlay from China Manufacturers

Material Selection for Optimal Performance

MSTR selects polyester for heat resistance and durability or polycarbonate for flexibility with gloss or velvet finishes, for the best fit for your application.

High-Precision Printing Techniques

Using offset, digital, and screen printing, MSTR delivers vivid colors, sharp graphics, and accurate color matching for a professional finish.

Embossing for Enhanced Usability

MSTR offers rim, pad, or dome embossing to create a tactile, responsive user experience, improving interaction with control panels.

Industrial-Grade Adhesive Application

MSTR applies high-performance 3M adhesives, ensuring secure attachment, strong bonding, and long-lasting durability in various environments.

Precision Die-Cutting and Window Design

MSTR die-cuts overlays to exact specifications, with clear windows, perforations, and through-holes for simple integration.

Rigorous Testing and Quality Control

MSTR performs rigorous quality controls for exact measurements, print quality and adhesive applications to guarantee a perfect finished product.

Custom Graphic Overlay Materials, Finishes, and Structural

MSTR offers fully customizable graphic overlays with a wide range of material, finish, and structural options to meet diverse application needs. We provide PET for industrial and high strength applications, PC for clearer prints for esthetically demanding applications, and specialty materials for chemical resistance, UV protection, and extreme temperatures.

Our surface treatments provide matte for less glare and enhanced wear resistance, gloss for maximum color and contrast, and optional anti-fingerprint, anti-scratch, and chemical-resistant coatings. Thickenesses range from 0.125mm to 0.25mm for tailored solutions for optimum performance and life.

Custom Graphic Overlay Appearance and Printing

MSTR provides totally custom graphic overlays with advanced printing and look capabilities to even further improve functionality and look. We offer silk screen printing for high-volume production with rich, durable colors and digital printing for small-batch customization with gradient effects and high-resolution graphics. Our precise color management ensures PANTONE and RAL color matching for brand consistency.

Transparent and semi-transparent windows are available for LED and LCD displays, with optional light-filtering colors. Backlight diffusion designs can be integrated for LED indicators or illuminated symbols. For a premium look and tactile enhancement, we provide embossing for raised keys, metallic finishes, and laser effects, ideal for high-end electronic applications.

Custom Graphic Overlay Bonding and Connection

MSTR offers customizable bonding and connection solutions to ensure secure and precise integration of graphic overlays with various surfaces. We provide high-quality adhesive options, including 3M and domestic double-sided tapes, suitable for metal, plastic, and glass substrates. For temporary applications, removable adhesives allow easy replacement and maintenance.

Our adhesive backing has standard smooth surface options and foam adhesives for improved adhesion on rough or irregular surfaces. For convenient accurate positioning, we offer alignment holes and positioning marks, making installation on your equipment easy and hassle-free. Each solution is designed to be long-lasting, dependable, and peak-performing in a variety of applications.

Custom Graphic Overlay Additional Features and Application Scenarios

MSTR provides incredibly durable graphic overlays designed to resist harsh environments, with scratch resistance, UV protection, and solvent resistance for outdoor gear, medical equipment, and industrial control panel use. We integrate advanced functionality such as ESD shielding to protect electronic components and EMI shielding to reduce electromagnetic interference, ensuring consistent device performance.

Our overlays are specially made for industries as diverse as industrial machinery requiring wear resistance, medical devices which require chemical resistance and antimicrobial activity, consumer electronics with best-class printing for brand recognition, to automotive control panels that must withstand high heat and harsh environments. Each solution is made to last, to be accurate, and to be reliable.